Understanding the Impact of Short Pin Length on Through-Hole Components

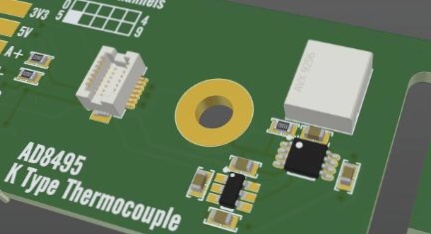

When dealing with through-hole components on a PCB, it’s crucial to consider the pin length in relation to the PCB thickness. If the pin length is smaller than the PCB thickness, it raises concerns about the component’s stability and long-term performance.

One common scenario is when you need to mount a PCB flush to a substrate, ruling out the option of using pins that stick out. While hand soldering may seem feasible initially, there are potential long-term issues that could arise from this setup.

It’s essential to assess the mechanical strength and electrical connections in such cases. Short pin lengths may compromise the reliability of the component, leading to issues like poor solder joints, mechanical stress, and thermal management challenges.

Latest Insights:

- Recent studies suggest that inadequate pin length can result in increased susceptibility to vibration-induced failures in through-hole components.

- Manufacturers are developing innovative solutions to address the limitations of short pin lengths, such as specialized soldering techniques and reinforced mounting structures.

- Engineers are exploring alternative component placement strategies to mitigate the risks associated with short pin lengths, emphasizing the importance of thorough testing and validation.

Considering these factors, it’s advisable to consult with PCB experts and explore alternative component options to ensure the reliability and longevity of your PCB assembly.