Key Points About Aerospace PCB Assembly

- Fabrication

- Design

- Assembly

Designing Military and Aerospace PCB Assembly involves special considerations:

Mil-spec grade components: Military-grade components with tight tolerance 1-2 percent are essential.

Current load: PCBs must withstand high current loads.

High & Low-frequency components: Clear differentiation is crucial to prevent signal quality issues.

Clock signal: Protect the clock signal from interference by enclosing it in aluminum.

Heat resistant material: Use quality materials like FR408 and Pyralux to endure extreme temperatures.

Thermal compounds: Utilize thermal compounds for heat dissipation.

Pre-tinned wires: Braided wires should be pre-tinned for better solderability.

Press-fit components: Use press-fit components to prevent vibration-induced faults.

Finishing material: Choose appropriate finishing materials for durability.

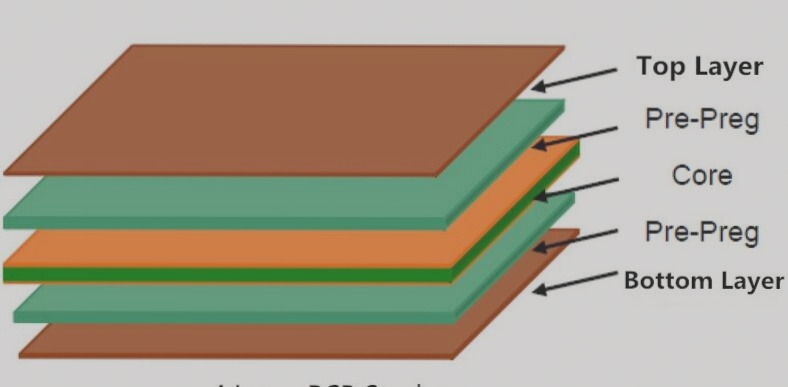

The Importance of Choosing the Right Materials for PCB Performance

- Lead-free HASL

- Immersion silver

- Electrolytic Nickel and gold

- Electroless Nickel with gold coating

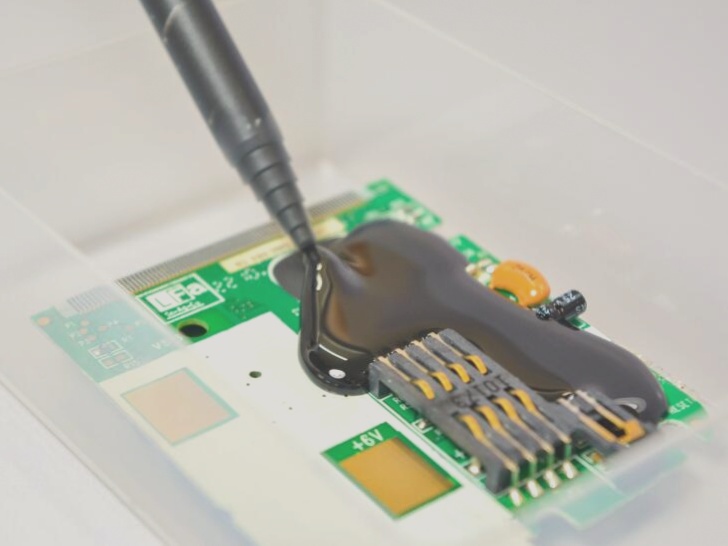

Enhancing PCB Performance through Coating

Sprays (Acrylic based) provide an additional protective layer for PCBs.

The Significance of Software in PCB Design

The software used in PCB design significantly impacts board quality by aiding in load calculations and necessary design modifications.

Optimizing PCB Routing for Efficient Current Flow

Maintain a 45-degree routing angle for smooth current flow through the circuit.

Adhering to Industry Standards for Quality Assurance

Manufacture Aerospace and Military grade PCBs according to MIL-50884, MIL-PRF-31032 & MIL-PRF55110 standards.

Aerospace and Military Applications of PCBs

- Ground stations

- Detection systems

- Satellite equipment

- FADEC (Full Authority Digital Engine Control System)

- CADC (Central Air Data Computers)

- Electronic Flight Instrumental System

Utilization of Military Grade PCBs in Various Applications

- Rugged computers and laptops

- Robotic systems

- Mortars and Artillery guns

- Communication systems and Defense navigation

- UAVs and unmanned vehicles

- Base security and camp protection

Key Considerations for Aerospace PCB Manufacturing

The manufacturing process for Aerospace PCBs differs from commercial PCBs due to their unique application requirements. Extra care and attention are essential to ensure functionality in harsh environments.

WellCircuits Electronics: Your Partner for Military & Aerospace PCB Assembly

Planning a startup for Aerospace PCB board assembly? Consult WellCircuits Electronics Services, a premier manufacturer of PCB Assembly for Military & Aerospace, offering expertise and quality services.

Expert PCB Solutions

Looking for professional PCB services? You’ve come to the right place! Our team of experts specializes in providing top-notch PCB solutions tailored to meet your specific needs.

Why Choose Us?

- Years of experience in the industry

- High-quality and reliable PCB products

- Customized solutions for every project

- Fast turnaround times

Our Services Include:

- PCB design and layout

- Prototype assembly

- PCB fabrication

- Testing and quality control

Get in Touch

Ready to get started? Contact us today to discuss your PCB needs and find out how we can help you achieve your project goals.