Understanding RoHS Directive and Its Impact on Electronic Products

What is RoHS?

The Restriction of Hazardous Substances (RoHS) is a crucial EU legislation standard that came into effect on July 1, 2006. It aims to regulate the materials and processes used in electronic and electrical products to promote human health and environmental protection.

Key Points of RoHS Directive

- Eliminates six substances: lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls, and polybrominated diphenyl ethers

- Lead content must not exceed 0.1%

EU RoHS and WEEE Directives

The Waste Electrical and Electronic Equipment (WEEE) Directive and RoHS Directive cover 10 categories and 102 products for hazardous substance restriction and scrap recovery management.

Categories of Restricted Substances

- Mercury: thermostats, sensors, switches, bulbs

- Lead: solder, glass, PVC stabilizer

- Cadmium: switches, connectors, PCBs, batteries

- Hexavalent Chromium: metal corrosion coating

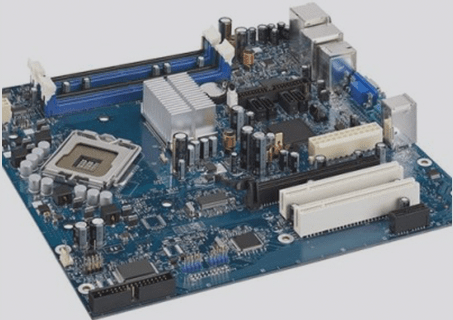

- Polybrominated Biphenyls (PBB): flame retardant, PCBs

- Polybrominated Diphenyl Ether (PBDE): flame retardant, PCBs

RoHS Testing Principles

Products are tested for harmful substances according to material types, including heavy metals and brominated flame retardants.

RoHS Compliance Limits

- Cadmium: < 100ppm

- Lead: < 1000ppm

- Mercury: < 1000ppm

- Hexavalent Chromium: < 1000ppm

Reasons for RoHS Implementation

Rising concerns over heavy metals in electronics, such as cadmium in cables and lead in soldering tin, led to the need for RoHS compliance.

RoHS Implementation Date

RoHS was enforced on July 1, 2006, prohibiting products with harmful substances from entering the EU market.

Products Covered by RoHS

RoHS targets all electrical and electronic products potentially containing harmful substances, including white goods, black goods, IT products, and medical equipment.

Current RoHS Progress

The RoHS directive continues to drive innovation in electronic manufacturing for safer and environmentally friendly products.

The Impact of RoHS on China’s Electronic Industry

- Large companies like SONY are taking measures to comply with RoHS regulations by using lead-free soldering and ink in their products.

- In 2004, the Ministry of Information Industry in China introduced measures similar to RoHS to prevent electronic information product pollution.

- China’s mechanical and electrical products, accounting for 55% of exports, are facing environmental barriers due to RoHS compliance issues with the EU.

- The Chinese government is actively studying countermeasures and implementing regulations to address environmental directives.

- Starting from July 1, 2006, electronic information products in China must not contain toxic substances like lead, mercury, and cadmium.

- The establishment of the “Working Group on Pollution Prevention and PCB Standards for Electronic Information Products” aims to set standards in line with China’s national conditions.

Overall, the impact of RoHS on China’s electronic industry has led to significant changes in manufacturing processes and regulations to meet international environmental standards.