1. As a PCB expert, I am familiar with the common drilling methods used in PCB fabrication, which include through holes, blind holes, and buried holes.

2. Through holes are drilled all the way through the PCB, allowing components to be soldered to both sides of the board.

3. Blind holes are drilled to a specific depth, only extending partway through the PCB, and are used for components that do not require connections on both sides.

4. Buried holes are similar to blind holes, but they are located between inner layers of the PCB and are not visible from the outer layers.

5. Each drilling method has its own advantages and considerations, and understanding these differences is crucial in the design and manufacturing of PCBs. 1. Through holes

1. Through holes

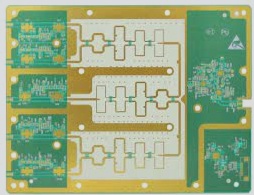

Through-holes (VIAs) are common holes used to conduct or connect copper foil lines between conductive patterns in different layers of the circuit board. They include blind holes and buried holes, but cannot accommodate component lead legs or other reinforcement materials. Due to the accumulation of many copper foil layers, each layer is covered with an insulation layer, preventing direct communication between copper foil layers. Signal connection is achieved through the through hole (VIA), hence the name.

Features: To meet customer needs, the circuit board through-holes must be plated, requiring changes to the traditional aluminum plug process. The use of white mesh enables stable production and reliable quality. The conduction hole mainly plays the role of connecting the circuit, in line with the electronic line. The rapid development of the industry has also led to higher requirements for the process and surface mount technology of printed circuit board production.

The plugging process of through-holes requires meeting the following requirements: 1. Copper should be found in the through-hole, and solder stopper can be plugged or not. 2. Tin lead should be present within the through-hole, with a certain thickness requirement (4um). Solder resistance ink should not be present in the hole, to avoid tin beads. 3. The pass-through hole must have solder resistance ink plug hole, opaque, with no tin ring, tin bead, and flat requirements.

2. Blind holes

Blind holes: these are electroplated holes connecting the outermost circuit in the PCB with the adjacent inner layer. As they are not visible from the opposite side, they are referred to as blind holes. They serve to increase the utilization of space between PCB circuit layers, providing a through-hole to the surface of the printed board.

Features: Blind holes are located on the top and bottom surfaces of the circuit board and have a certain depth for linking the surface line with the underlying inner line. The depth of the holes usually does not exceed a certain ratio (aperture). Special attention must be given to ensure the drilling hole depth (Z-axis) is appropriate, as improper drilling can cause plating difficulties.

3. Buried holes

Buried holes are links between any circuit layers inside the PCB that do not extend to the outer layer. This type of hole is not channeled to the surface of the circuit board.

Features: This process requires drilling at the time of individual circuit layers, followed by local bonding of the inner layer and electroplating treatment, before finally completing all bonding. This method is more time-consuming and, consequently, more expensive. It is usually used for high-density circuit boards to increase usable space on other layers.

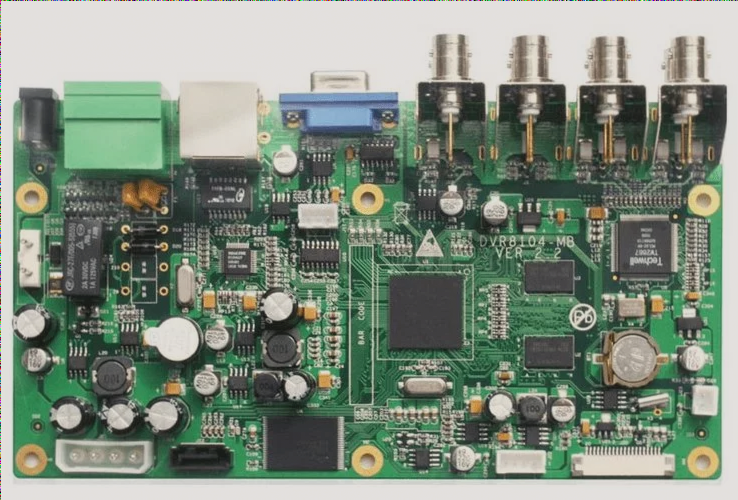

In the PCB production process, drilling is crucial as it provides electrical connections and fixed device functions. Improper drilling can result in devices not being properly fixed on the circuit board, affecting its functionality or leading to the scrapping of the entire board.

The rapid development of the electronics industry has driven the need for high-density, high-precision PCBs. Different types of through-holes, such as blind holes and buried holes, have emerged to meet these evolving requirements.

2. Through holes are drilled all the way through the PCB, allowing components to be soldered to both sides of the board.

3. Blind holes are drilled to a specific depth, only extending partway through the PCB, and are used for components that do not require connections on both sides.

4. Buried holes are similar to blind holes, but they are located between inner layers of the PCB and are not visible from the outer layers.

5. Each drilling method has its own advantages and considerations, and understanding these differences is crucial in the design and manufacturing of PCBs.

1. Through holes

1. Through holesThrough-holes (VIAs) are common holes used to conduct or connect copper foil lines between conductive patterns in different layers of the circuit board. They include blind holes and buried holes, but cannot accommodate component lead legs or other reinforcement materials. Due to the accumulation of many copper foil layers, each layer is covered with an insulation layer, preventing direct communication between copper foil layers. Signal connection is achieved through the through hole (VIA), hence the name.

Features: To meet customer needs, the circuit board through-holes must be plated, requiring changes to the traditional aluminum plug process. The use of white mesh enables stable production and reliable quality. The conduction hole mainly plays the role of connecting the circuit, in line with the electronic line. The rapid development of the industry has also led to higher requirements for the process and surface mount technology of printed circuit board production.

The plugging process of through-holes requires meeting the following requirements: 1. Copper should be found in the through-hole, and solder stopper can be plugged or not. 2. Tin lead should be present within the through-hole, with a certain thickness requirement (4um). Solder resistance ink should not be present in the hole, to avoid tin beads. 3. The pass-through hole must have solder resistance ink plug hole, opaque, with no tin ring, tin bead, and flat requirements.

2. Blind holes

Blind holes: these are electroplated holes connecting the outermost circuit in the PCB with the adjacent inner layer. As they are not visible from the opposite side, they are referred to as blind holes. They serve to increase the utilization of space between PCB circuit layers, providing a through-hole to the surface of the printed board.

Features: Blind holes are located on the top and bottom surfaces of the circuit board and have a certain depth for linking the surface line with the underlying inner line. The depth of the holes usually does not exceed a certain ratio (aperture). Special attention must be given to ensure the drilling hole depth (Z-axis) is appropriate, as improper drilling can cause plating difficulties.

3. Buried holes

Buried holes are links between any circuit layers inside the PCB that do not extend to the outer layer. This type of hole is not channeled to the surface of the circuit board.

Features: This process requires drilling at the time of individual circuit layers, followed by local bonding of the inner layer and electroplating treatment, before finally completing all bonding. This method is more time-consuming and, consequently, more expensive. It is usually used for high-density circuit boards to increase usable space on other layers.

In the PCB production process, drilling is crucial as it provides electrical connections and fixed device functions. Improper drilling can result in devices not being properly fixed on the circuit board, affecting its functionality or leading to the scrapping of the entire board.

The rapid development of the electronics industry has driven the need for high-density, high-precision PCBs. Different types of through-holes, such as blind holes and buried holes, have emerged to meet these evolving requirements.