Understanding PCB and PCBA in Electronics

Introduction

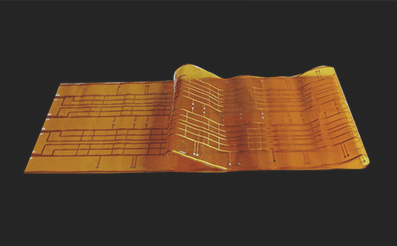

PCB (Printed Circuit Board) is a vital electronic component that provides support and electrical connections for electronic parts, earning it the title of the “mother of electronics.” Before PCBs, wires were directly used for connections, but now PCBs dominate the industry.

PCB Production Process

- Contacting the manufacturer

- Cutting and drilling

- Copper sinking and pattern transfer

- Pattern plating and film removal

- Etching and green oil application

- Character printing and gold-plated fingers

- Final steps: forming, testing, and inspection

Advantages of PCBs

PCBs offer high density, reliability, design flexibility, ease of manufacture, testability, and maintainability.

Evolution to PCBA

PCBA (Printed Circuit Board Assembly) involves SMT (Surface Mount Technology) or DIP (Dual In-line Package) processes to populate a PCB with components.

SMT (Surface Mount Technology)

SMT places small components on the PCB without the need for drilled holes. It involves PCB positioning, solder paste printing, mounter placement, reflow soldering, and inspection.

DIP (Dual In-line Package)

DIP inserts components into the PCB, suitable for larger parts. Methods include manual or robotic insertion, with steps like adhesive application, insertion, wave soldering, and cleaning.

PCB vs. PCBA

PCBA is the completed assembly of a PCB, while PCB refers to the bare board. Understanding this difference is crucial for electronic solution providers seeking suitable PCBA suppliers for their research and production needs.

Explore the world of PCB and PCBA to enhance your electronic projects!