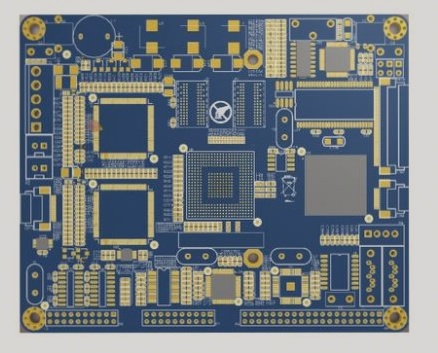

1. PCB board wiring is the process of laying a path for connecting various devices with power and signal connections.

2. It involves the routing of copper traces on the PCB to establish the necessary connections between the components.

3. PCB board wiring requires careful planning and consideration of factors such as signal integrity, power distribution, and electromagnetic interference.

4. With the advancement of technology, the complexity of PCB board wiring has increased, requiring expertise in design and layout optimization.

5. Proper PCB board wiring is crucial for the overall performance and reliability of electronic devices.

6. It is essential to follow best practices and standards to ensure the functionality and safety of the PCB design.

7. The use of advanced software tools and automation has significantly improved the efficiency and accuracy of PCB board wiring processes.

8. Overall, PCB board wiring plays a critical role in the successful functioning of electronic devices and systems.

PCB board wiring

1. In PCB design, wiring is an important step in completing product design. It can be said that the previous preparation work is done for it. In the entire PCB design, the wiring design process has the highest limit, the most detailed skills, and the largest workload. PCB board wiring includes single-sided wiring, double-sided wiring, and multi-layer wiring.

2. There are also two ways of wiring: automatic wiring and interactive wiring. Before automatic routing, it is possible to use interactive pre-wiring for lines with strict requirements. The wiring between the input and output ends should avoid adjacent parallelism to avoid reflection interference. If necessary, ground wires should be added for isolation. The wiring of adjacent layers should be perpendicular to each other, while parallel layers are prone to parasitic coupling.

3. The wiring rate of automatic wiring depends on a good layout, and the routing rules can be pre-set, including the number of bends in the wiring, the number of through holes, and the number of steps. Generally, exploratory wiring is carried out first to quickly connect short lines, and then maze wiring is carried out. The wiring to be laid is first optimized for global wiring paths, which can disconnect the laid lines as needed.

4. PCB board wiring rules

a. The distance between SMD devices should be greater than.

b. The distance between the outer side of the SMD device pad and the outer edge of adjacent THD components should be greater than 2mm.

5. Ground circuit rules

a. The minimum rule of the loop is that the area of the loop formed by the signal line and its loop should be as small as possible.

b. When segmenting the ground plane, it is necessary to consider the distribution of the ground plane and important signal lines to prevent problems caused by ground plane slots and other factors.

c. In the design of double-layer boards, while leaving sufficient space for the power supply, the remaining part should be filled with reference ground and some necessary holes should be added to effectively connect the double-sided ground signals.

d. For some key signals, ground wire isolation should be used as much as possible.

e. For some high-frequency designs, special consideration should be given to the ground plane signal circuit problem, and it is recommended to use multi-layer boards.

6. CrossTalk control

a. Refers to the mutual interference caused by long parallel wiring between different networks on a PCB, mainly due to the distributed capacitance and inductance between parallel lines.

b. The main measures to overcome crosstalk are to increase the spacing of parallel wiring and follow the 3W rule.

c. Insert a grounded isolation wire between parallel lines.

d. Reduce the distance between the wiring layer and the ground plane.

7. Shielding protection

a. The corresponding ground circuit rules are actually aimed at minimizing the circuit area of the signal as much as possible, and are commonly seen in some important signals, such as clock signals and synchronization signals.

b. For signals that are particularly important and have high frequencies, a copper shaft cable shielding structure design should be considered, which means that the wires on and off the line are separated by ground wires on the left and right sides.

8. Direction control rules for wiring

a. The routing direction of adjacent layers is in an orthogonal structure.

b. Avoid running different signal lines in the same direction in adjacent layers to reduce unnecessary inter-layer interference.

c. When it is difficult to avoid this situation due to board structure limitations (such as certain backplanes), especially when the signal rate is high, it should be considered to isolate each wiring layer with a ground plane and each signal line with a ground signal line.

9. Open loop inspection rules for wiring

a. Dangling lines with one end floating are not allowed, mainly to avoid “antenna effects” and reduce unnecessary interference radiation and reception.

10. Impedance matching check rules

a. The wiring width of the same network should be consistent.

b. The change in the line width will cause an uneven characteristic impedance of the line.

c. Under certain conditions, it may not be possible to avoid changes in line width, and the effective length of inconsistent parts in the middle should be minimized as much as possible.

11. Wiring closed-loop inspection rules

a. Prevent signal lines from forming self-loops between different layers.

b. This type of problem is prone to occur in the design of multi-layer boards, and self-circulation will cause radiation interference.

12. Control rules for branch length of wiring

a. Try to control the length of the branches as much as possible, with the general requirement being Tdelay<=Trise/20.

13. Resonance rules for wiring

a. Mainly for high-frequency signal design, the wiring length should not be an integer multiple of its wavelength to avoid resonance phenomenon.

14. Line length control rules

a. The short line rule is that when designing, the wiring length should be as short as possible to reduce interference caused by excessively long wiring.

b. Especially for important signal lines, it is important to place their oscillators very close to the device.

15. Integrity rules for power and ground layers

a. For areas with dense conductive holes, attention should be paid to avoiding interconnections between the holes in the excavated area of the power supply and the formation, forming a division of the plane layer.

16. Rules for overlapping power and ground layers

a. Different power layers should avoid overlapping in space.

b. The main purpose is to reduce interference between different power sources, especially for some power sources with significant voltage differences.

PCB board wiring skills and precautions

1. Precautions for wiring between the power supply and ground wire

a. Coupling capacitance shall be added between the power supply and the ground.

b. Try to widen the power and ground wires as much as possible.

c. A large area of copper layer can be used as a ground wire, connecting unused areas on the printed circuit board to the ground for use as a ground wire.

2. Processing when mixing digital and analog circuits

a. Consider the issue of mutual interference between digital and analog circuits.

b. High-frequency signal lines should be as far away from sensitive analog circuit components as possible.

c. Only at the connection between the PCB and the outside world is there a short circuit between the ground of the digital circuit and the ground of the analog circuit.

3. Treatment of Line Corners

a. Corners have the worst effect on the thickness variation of lines, with a right angle being the worst, a 45-degree angle being better, and a rounded corner being the best.

Good PCB board wiring can handle practical issues such as adjusting the component layout, handling wire thickness, spacing, and routing to meet production standards.

2. It involves the routing of copper traces on the PCB to establish the necessary connections between the components.

3. PCB board wiring requires careful planning and consideration of factors such as signal integrity, power distribution, and electromagnetic interference.

4. With the advancement of technology, the complexity of PCB board wiring has increased, requiring expertise in design and layout optimization.

5. Proper PCB board wiring is crucial for the overall performance and reliability of electronic devices.

6. It is essential to follow best practices and standards to ensure the functionality and safety of the PCB design.

7. The use of advanced software tools and automation has significantly improved the efficiency and accuracy of PCB board wiring processes.

8. Overall, PCB board wiring plays a critical role in the successful functioning of electronic devices and systems.

PCB board wiring

1. In PCB design, wiring is an important step in completing product design. It can be said that the previous preparation work is done for it. In the entire PCB design, the wiring design process has the highest limit, the most detailed skills, and the largest workload. PCB board wiring includes single-sided wiring, double-sided wiring, and multi-layer wiring.

2. There are also two ways of wiring: automatic wiring and interactive wiring. Before automatic routing, it is possible to use interactive pre-wiring for lines with strict requirements. The wiring between the input and output ends should avoid adjacent parallelism to avoid reflection interference. If necessary, ground wires should be added for isolation. The wiring of adjacent layers should be perpendicular to each other, while parallel layers are prone to parasitic coupling.

3. The wiring rate of automatic wiring depends on a good layout, and the routing rules can be pre-set, including the number of bends in the wiring, the number of through holes, and the number of steps. Generally, exploratory wiring is carried out first to quickly connect short lines, and then maze wiring is carried out. The wiring to be laid is first optimized for global wiring paths, which can disconnect the laid lines as needed.

4. PCB board wiring rules

a. The distance between SMD devices should be greater than.

b. The distance between the outer side of the SMD device pad and the outer edge of adjacent THD components should be greater than 2mm.

5. Ground circuit rules

a. The minimum rule of the loop is that the area of the loop formed by the signal line and its loop should be as small as possible.

b. When segmenting the ground plane, it is necessary to consider the distribution of the ground plane and important signal lines to prevent problems caused by ground plane slots and other factors.

c. In the design of double-layer boards, while leaving sufficient space for the power supply, the remaining part should be filled with reference ground and some necessary holes should be added to effectively connect the double-sided ground signals.

d. For some key signals, ground wire isolation should be used as much as possible.

e. For some high-frequency designs, special consideration should be given to the ground plane signal circuit problem, and it is recommended to use multi-layer boards.

6. CrossTalk control

a. Refers to the mutual interference caused by long parallel wiring between different networks on a PCB, mainly due to the distributed capacitance and inductance between parallel lines.

b. The main measures to overcome crosstalk are to increase the spacing of parallel wiring and follow the 3W rule.

c. Insert a grounded isolation wire between parallel lines.

d. Reduce the distance between the wiring layer and the ground plane.

7. Shielding protection

a. The corresponding ground circuit rules are actually aimed at minimizing the circuit area of the signal as much as possible, and are commonly seen in some important signals, such as clock signals and synchronization signals.

b. For signals that are particularly important and have high frequencies, a copper shaft cable shielding structure design should be considered, which means that the wires on and off the line are separated by ground wires on the left and right sides.

8. Direction control rules for wiring

a. The routing direction of adjacent layers is in an orthogonal structure.

b. Avoid running different signal lines in the same direction in adjacent layers to reduce unnecessary inter-layer interference.

c. When it is difficult to avoid this situation due to board structure limitations (such as certain backplanes), especially when the signal rate is high, it should be considered to isolate each wiring layer with a ground plane and each signal line with a ground signal line.

9. Open loop inspection rules for wiring

a. Dangling lines with one end floating are not allowed, mainly to avoid “antenna effects” and reduce unnecessary interference radiation and reception.

10. Impedance matching check rules

a. The wiring width of the same network should be consistent.

b. The change in the line width will cause an uneven characteristic impedance of the line.

c. Under certain conditions, it may not be possible to avoid changes in line width, and the effective length of inconsistent parts in the middle should be minimized as much as possible.

11. Wiring closed-loop inspection rules

a. Prevent signal lines from forming self-loops between different layers.

b. This type of problem is prone to occur in the design of multi-layer boards, and self-circulation will cause radiation interference.

12. Control rules for branch length of wiring

a. Try to control the length of the branches as much as possible, with the general requirement being Tdelay<=Trise/20.

13. Resonance rules for wiring

a. Mainly for high-frequency signal design, the wiring length should not be an integer multiple of its wavelength to avoid resonance phenomenon.

14. Line length control rules

a. The short line rule is that when designing, the wiring length should be as short as possible to reduce interference caused by excessively long wiring.

b. Especially for important signal lines, it is important to place their oscillators very close to the device.

15. Integrity rules for power and ground layers

a. For areas with dense conductive holes, attention should be paid to avoiding interconnections between the holes in the excavated area of the power supply and the formation, forming a division of the plane layer.

16. Rules for overlapping power and ground layers

a. Different power layers should avoid overlapping in space.

b. The main purpose is to reduce interference between different power sources, especially for some power sources with significant voltage differences.

PCB board wiring skills and precautions

1. Precautions for wiring between the power supply and ground wire

a. Coupling capacitance shall be added between the power supply and the ground.

b. Try to widen the power and ground wires as much as possible.

c. A large area of copper layer can be used as a ground wire, connecting unused areas on the printed circuit board to the ground for use as a ground wire.

2. Processing when mixing digital and analog circuits

a. Consider the issue of mutual interference between digital and analog circuits.

b. High-frequency signal lines should be as far away from sensitive analog circuit components as possible.

c. Only at the connection between the PCB and the outside world is there a short circuit between the ground of the digital circuit and the ground of the analog circuit.

3. Treatment of Line Corners

a. Corners have the worst effect on the thickness variation of lines, with a right angle being the worst, a 45-degree angle being better, and a rounded corner being the best.

Good PCB board wiring can handle practical issues such as adjusting the component layout, handling wire thickness, spacing, and routing to meet production standards.