Circuit Board Heat Dissipation Strategies

When dealing with heat generation on a PCB, there are various methods to enhance heat dissipation and prevent overheating issues.

1. Utilizing Heat Sinks and Heat Pipes

- For a small number of heat-generating components (less than 3), consider adding a heat sink or heat pipe to the device.

- If temperatures remain high, a heat sink with a fan can be employed for improved heat dissipation.

- When dealing with a large number of heating devices (more than 3), using a customized heat dissipation cover or a flat heat sink tailored to component heights can be effective.

- In cases of height inconsistencies during assembly, a thermal phase change thermal pad can be added to components to enhance heat dissipation.

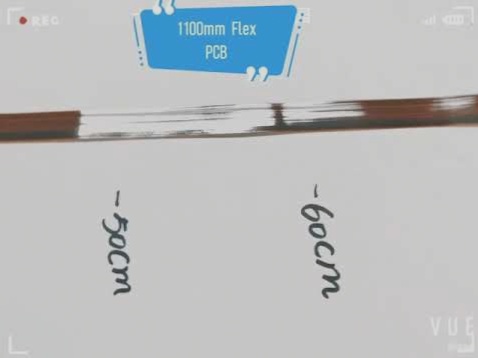

2. Enhancing PCB Heat Dissipation

Traditional PCB boards have limitations in heat dissipation, necessitating additional methods to manage heat effectively.

- Common PCB substrates like copper-clad/epoxy glass cloth lack efficient heat dissipation properties.

- Heat dissipation from component surfaces to the air is crucial as electronic products become smaller and generate more heat.

- Improving the PCB’s heat dissipation capacity through the board itself is essential to dissipate or emit heat effectively.

3. Optimizing Wiring Design for Heat Management

Effective wiring design plays a significant role in enhancing heat dissipation on PCBs.

- Increasing copper foil retention and incorporating thermally conductive holes can improve heat conduction.

- Calculating the PCB’s equivalent thermal conductivity helps assess its heat dissipation capabilities.

4. Strategic Device Placement for Cooling

Proper arrangement of devices on a printed board is crucial for efficient heat dissipation.

- Devices should be placed based on their heat generation and dissipation levels.

- High-power devices should be positioned near the board edge horizontally to reduce heat transfer paths.

- Temperature-sensitive devices are best placed in cooler areas to prevent overheating.

5. Ensuring Balanced Power Distribution

Evenly distributing power consumption across the PCB helps prevent hot spots and ensures consistent temperature performance.

- Placing high-power devices in optimal heat dissipation positions is recommended.

- Avoiding hot spots and maintaining uniform power distribution are essential for stable PCB performance.

By implementing these strategies, PCBs can effectively manage heat dissipation and prevent thermal issues, ensuring optimal performance and longevity of electronic devices.

Optimizing Thermal Management in PCB Design

When connecting high heat dissipation devices to the substrate, minimizing thermal resistance is crucial. Using thermal conductive materials, such as thermally conductive silica gel, on the device’s bottom surface and maintaining a sufficient contact area for heat dissipation can help meet thermal requirements.

Tips for Connecting Devices to the Substrate:

- Shorten the device lead length

- Consider the thermal conductivity of the lead material when selecting high-power devices; opt for larger cross-section leads when possible

- Choose devices with more pins for better heat dissipation

Device Package Selection Recommendations:

- Consider the device’s package description and thermal conductivity for optimal thermal design

- Ensure a good heat conduction path between the substrate and device package

- Avoid air partitions in the heat conduction path; use heat-conducting materials if necessary

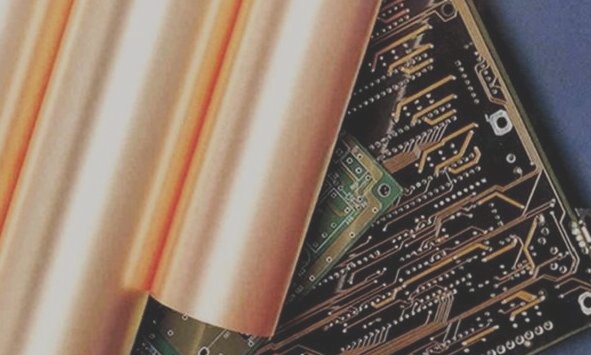

WellCircuits Limited specializes in high-precision double-sided, multi-layer, impedance-controlled circuit boards. Our products include HDI, thick copper, backplanes, rigid-flex, buried capacitance, golden finger, and more, catering to various customer needs.