Automatic Optical Inspection (AOI) in SMT Industry

1. AOI testing is a crucial aspect of the Surface Mount Technology (SMT) industry. AOI, short for Automatic Optical Inspection, is a state-of-the-art technology that has gained popularity in recent years. It provides features like automated scanning, real-time alerts, anomaly detection, and complete automation. Let’s explore the principles and benefits of AOI testing in SMT.

Principle of AOI Testing

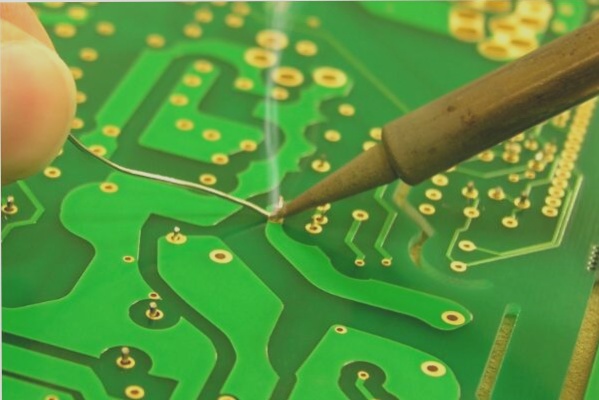

2. AOI testing employs optical principles by using cameras embedded in the equipment to scan the PCB. It captures images, compares them with approved data stored in the machine’s database, and evaluates the soldering quality of the PCB after image processing.

Advantages of AOI Detection

3. As electronic devices become smaller and PCB designs more complex, manual PCB inspection is becoming increasingly difficult. Manual inspection is slower than automated methods and is prone to human errors and fatigue. AOI technology offers a more efficient solution to these challenges.

Key Benefits of AOI Technology

- Rapid and accurate inspection of PCBs

- Reduction in human errors and fatigue

- Enhanced efficiency in the production process

- Real-time alerts for immediate issue resolution

- Automation leading to increased productivity

4. Despite the numerous advantages AOI testing provides over manual inspection, there are limitations to consider. Technical blind spots may arise, resulting in incorrect assessments. In such instances, manual intervention is necessary to maintain product quality.