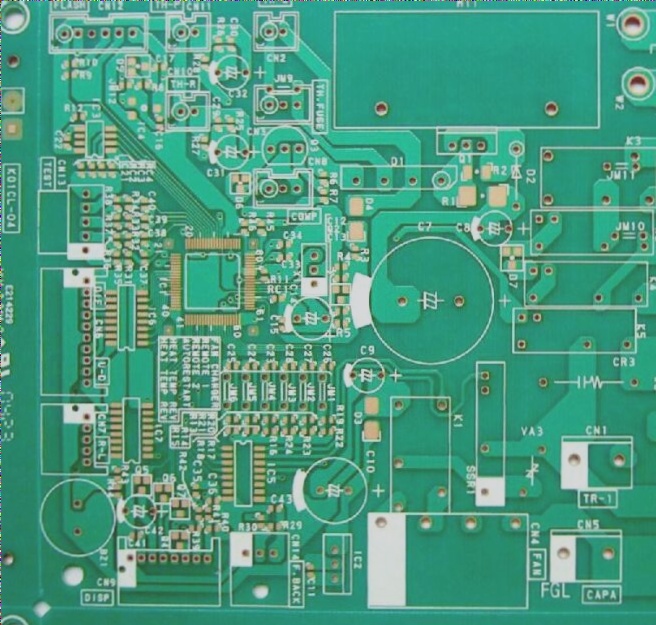

With so many varieties of integrated circuits and components available, there’s a seemingly infinite number of configurations and combinations that you can use. This is a considerable concern when dealing with surface mount technology (SMD) devices.

However, even if you’re working with whole components, assembling a PCB board is a task that will come up repeatedly for years on end.

These days, PCBs have become an essential component of technology. However, assembling a PCB board is not so easy for newbies. This blog will help you!

Top 13 Ways to Assemble A PCB Board

- Learn the Basics of PCB Circuit Boards

Step one in creating a PCB board is understanding how they work. The essential parts of any circuit board are the copper planes, called traces, which carry signals throughout the device. Atoms are connected by pads on which components are attached.

Pads are small areas of copper on the surface of the board, usually circular or rectangular shaped, and they have holes or slots in them for connections to other parts of the board or for inserting wires or legs on components.

Printed on each side of each PCB board is a legend that shows where each part goes; make sure that this matches your diagram before continuing with your project.

- Understand Good Assembly Practices

Not every aspect of PCB assembly is as well standardized as others. For instance, it’s generally understood that you should use a flux pen when soldering. Still, there are disagreements about how to solder specific components, what materials to use for certain parts of a PCB, or how to manage the placement of elements on the board.

When learning how to assemble a PCB board, it’s essential to do your research before starting. There are many different ways to sell an SMT part, and some work better than others.

You can learn from experience, but it’s much faster and easier if you know what to expect when trying something first.

It might seem like it will take longer at first, mainly as you learn about techniques that didn’t work for you or ones that turned out not to be worth your time, but this knowledge will help you tremendously in the long run!

- Observe Proper Term Usage

Suppose you’re not familiar with electronic terminology and abbreviations. This will come as a surprise: there are specific terms used to describe parts and functions on a printed circuit board, and they may differ slightly from the terms used in other fields (i.e., mechanical and electronics). To avoid confusion later, make sure all parties involved use the exact words.

- Take Note of the Specific Instructions for Each Assembly Technique

There are many ways to assemble a PCB board; however, each method has unique features and instructions. Always read the instructions carefully before you begin any PCB assembly project. The instructions will tell you what tools to use and how. This is especially important because each tool has its own set of instructions and tips for proper use.

It is recommended that you read over all the assembly methods before construction and follow the steps required for each process.

- Plan and Prepare Your Tools

Various tools can be used when creating a PCB board. Depending on your budget, you can choose how many devices you want to use and what will work best for your project.

It is essential to plan to ensure that you have everything available before getting started with the construction of your device.

- Review Your Design

It is always helpful to review your design quickly before starting the assembly process. This can help ensure no errors or problems with your initial strategy and save time during construction if any changes need to be made. This way, it also provides that you are working fully understanding what is required.

- Keep Your Work Area Clean

This is an easy step to forget, but keeping your work area clean can make the process significantly more accessible, especially if parts need to be moved around or taken off. Make sure your space is well-lit and clear of clutter to find what you need quickly.

- Be Aware Of Soldering Guidelines

It is imperative to be aware of soldering guidelines before starting to solder your printed circuit board. If you do not follow the rules and recommendations, you will probably get a malfunctioning board or even damage the board.

Soldering is an operation that generates heat and can easily damage sensitive electronic components, so you must know how much heat you can use without damaging the parts. It would help if you used low temperatures for soldering.

- Beware of Heat

While assembling a PCB board, there is one thing that you should be aware of: heat. When you are soldering components, the solder has to melt to allow the connection between the two wires.

However, most of us don’t realize that excess heat can ruin your board and make soldering difficult or impossible. If it takes longer than this, stop immediately and let it cool down for two minutes before continuing. You may need to repeat this process many times during the assembly process.

One way to avoid excessive heat is by using a low-wattage iron. Using an iron with too much power will cause it to get hot quickly and make matters worse.

A 40-watt iron is high enough for most boards, and even then, it should be used for as little time as possible. Another thing you can do is put something between the PCB board and your iron’s tip.

A small piece of aluminum foil is good—it won’t conduct heat very well but still allows you to get enough pressure on the tip to get a good connection.

- Know-How to Solder Using a Wave Machine

Assembling a circuit board isn’t as difficult as it might seem, but there are a few tips and tricks. Working with printed circuit boards is a great skill to have, and it’s not something that you should let get rusty. Luckily, this guide can help you re-familiarize yourself with the basics of PCB assembly.

The most important thing to remember is that you’ll need the right equipment to make this work. A soldering iron, solder, flux pen, and the correct wire will make your job easier.

You’ll be using a wave machine to create a buzz or flash of electricity that turns the solder into liquid, so you can use it to connect different parts of the circuit.

Some people also like to use a PCB drilling machine, but this isn’t strictly necessary if you’re making one or two small circuit boards. It’s faster if you’re having trouble finding the exact drill bits in the sizes you need for your project.

- Learn To Solder Using a Reflow Oven

Reflow ovens are great for teaching new soldiers how to solder, and they’re also great for advanced soldiers working with surface-mounted components. Reflow ovens use higher temperatures, so you don’t have to worry about the effects of heat on your board.

Many people like to use a reflow oven for SMD soldering because the temperature is tightly controlled, giving you a very professional-looking result.

If you want to learn the basics, check out this video from Sparkfun. If you are starting in electronics, one of the best ways is by using a reflow oven to solder your first circuit together!

- Choosing a PCB Software

You will be using this software when creating your PCB board. There are many types of software available, but the most common one is the accessible version of Eagle CAD.

This software is easy to use and allows you to have great control over all aspects of your project, including the shape and size of each component on your circuit board.

- Getting Your Gerber Files Ready

The Gerber files are a set of files that contain all of the information regarding layers, copper pours, silkscreen overlays, and more. These files are essential in creating your PCB boards because they let manufacturers know how to start your printed circuit boards.

These files can only be created once you have completed your design and finalized all of the components you want.

Final Thoughts

Making a PCB board is not easy, but that does not mean doing it yourself is impossible or very difficult. There are many methods for creating your PCB board, and even you can make a PCB board at home. It’s up to you to choose the suitable way that works well and produces a high-quality result.

Every assembly process is unique and has its pros and cons. However, in the end, it all comes down to the designer’s preference and their project’s budget. Assembling a PCB board can be a time-consuming but rewarding process that you should do yourself.

Hopefully, these methods and tricks will help you in the future when you need to create a PCB board design. If you know some other exciting ways that are not included in this list, you can always leave a comment below and share it with us!