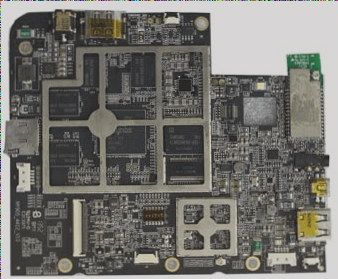

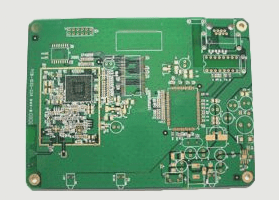

1. A PCB (Printed Circuit Board), also known simply as a printed circuit board, is a vital electronic component that provides support for electronic parts and serves as a medium for their electrical interconnection. It derives its name from the process of electronic printing used in its fabrication.

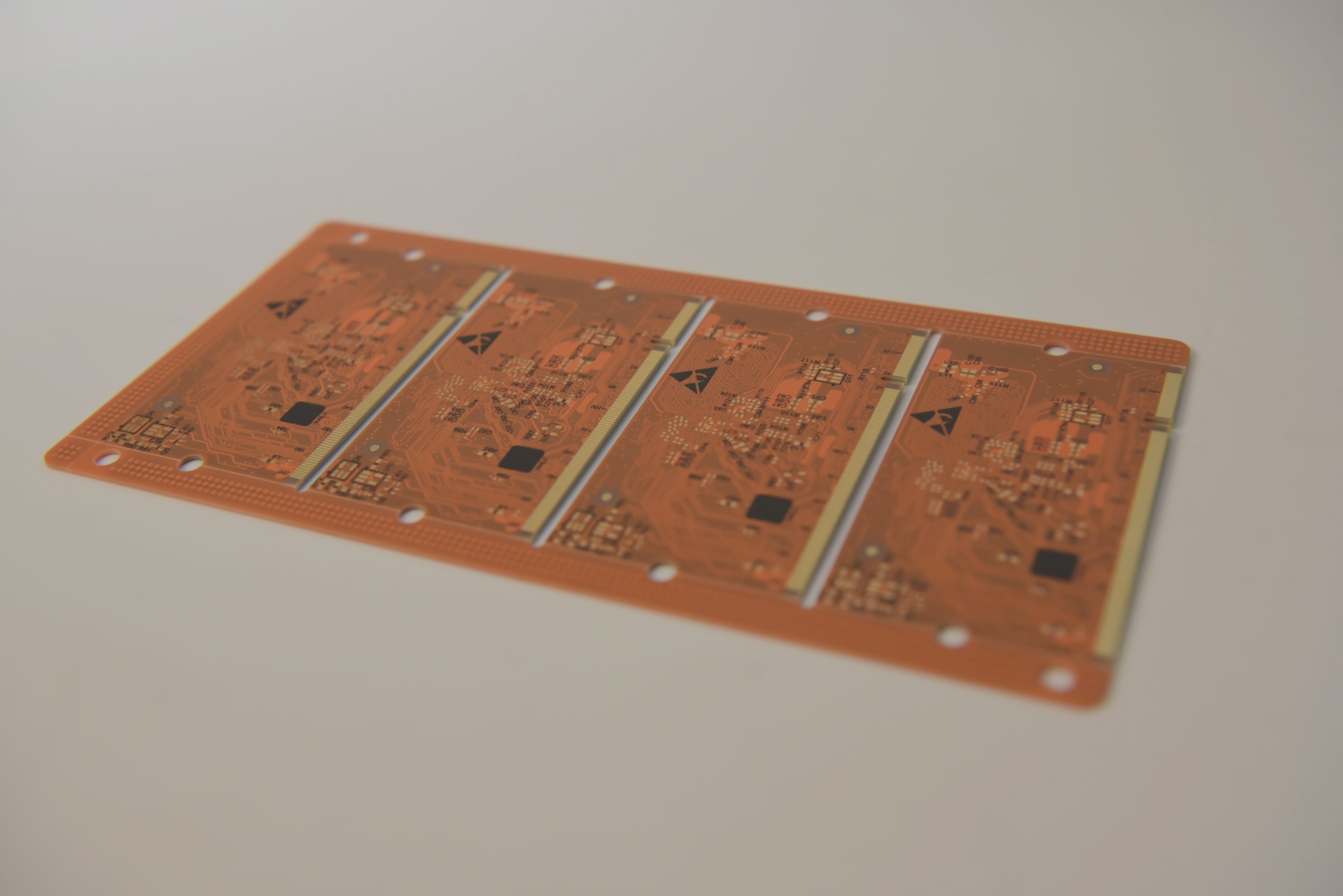

2. An FPC (Flexible Printed Circuit Board), or flexible circuit board, offers high reliability and exceptional flexibility compared to traditional rigid PCBs. It boasts characteristics such as high wiring density, lightweight construction, slim profile, and excellent flexibility.

3. COF (Chip on Film) is a soft film technology used to mount integrated circuits (ICs) onto flexible circuit boards. This method involves bonding chip carriers to flexible substrate circuits, achieving high-density configurations, reduced weight and volume, and facilitating straightforward and complete installation.

4. The COF flexible packaging substrate represents an advanced offshoot of FPC technology. It plays a crucial role during chip packaging by providing structural support, circuit connectivity, and insulation. It enhances chip protection, improves signal transmission rates and fidelity, ensures impedance matching, relieves stress, aids in heat dissipation, and enhances moisture resistance.

1. **FCCL Soft Copper Foil Substrate** (Flexible Copper Clad Laminate), also known as flexible copper clad, flexible copper clad, or soft copper clad, is a substrate used in FPC (Flexible Printed Circuit) processing.

In addition to its thin, light, and flexible nature, FCCL features a polyimide base film (PI film), providing excellent electrical and thermal properties, as well as superior heat resistance. FCCL is categorized into two types: the traditional three-layer soft board matrix (3L FCCL) and the newer two-layer soft board matrix (2L FCCL). These two types are manufactured differently, leading to distinct material properties.

2. In terms of application, the products made from the two types of FCCL serve different purposes. 3L-FCCL is typically used for large-scale soft board products, while 2L-FCCL is preferred for advanced soft board manufacturing, such as for soft cardboard, COF, and more.

PI film, or polyimide film, is a high-temperature resistant organic polymer film, known for its electrical grade insulation and heat resistance. It is highly elastic, has a low coefficient of expansion, and meets various electronic performance standards. As a specialized engineering material, electronic-grade PI film is unparalleled by other polymers. It offers excellent heat resistance, oxygen resistance, mechanical properties, electrical performance, and chemical stability, often being referred to as “gold film.”

3. Currently, the largest application of microelectronic PI film is in flexible copper-clad laminates (FCCL), which serve as key insulating substrates.

The Tpi PI carbonized film, produced through polymer sintering, is a deep-processing product of PI film. Its exceptional thermal and electrical conductivity, along with features like battery shielding and stealth capabilities, make it ideal for use in flexible semiconductor devices, heat-dissipating chips, flexible displays, and solar power generation systems.

4. **Current Market of FPCs**

The largest application of FPCs is in smartphones, accounting for over 40% of total output. Consumer electronics generally require 2-15 FPC products, with smartphones typically using 10-15, and leading models such as Apple’s reaching 16-18 FPCs. As smartphone technology continues to innovate—such as with dual-lens cameras, OLED screens, fingerprint recognition, and wireless charging—demand for FPC products is set to increase.

5. **Apple’s Role in FPC Innovation**

Apple plays a crucial role in driving global FPC technology forward. In 2010, the iPhone 4 introduced the use of multi-layer HDI (High-Density Interconnect) boards, marking the start of the mobile phone industry’s lightweight transition. By 2014, the iPhone 6’s fingerprint recognition technology paved the way for FPC’s role in mobile security. Subsequent iPhone models, such as the iPhone 7 with its dual-camera system and the iPhone X with OLED displays and wireless charging, have significantly expanded FPC’s application, generating new market opportunities.

Additionally, Apple remains the primary customer for the world’s six largest FPC manufacturers.

6. **Vertical Integration in the Flexible PCB Industry**

The flexible PCB industry exhibits a clear vertical division of labor. Leading companies in developed countries control core processes such as key material technology, raw material supply, product development, design, marketing, and branding. Meanwhile, production and assembly tasks are often outsourced to professional factories in developing nations, establishing a system of independent, specialized labor. This includes raw material production, substrate manufacturing, chip packaging, and template assembly.

7. **China’s Rapid Growth in FPC Manufacturing**

China’s FPC manufacturing industry has seen rapid growth, driven by industrial transfers and the expanding consumer electronics market. The domestic FPC market now exceeds 30 billion yuan, representing over 30% of the global industry share. Currently, around one-third of FPC manufacturing enterprises in mainland China are foreign-invested, accounting for approximately 80% of the total output value.

8. **Future Application Trends**

1. **Smartphone Evolution Drives FPC Demand**

The continuous advancement of smartphones, especially in features like mobile payment, fingerprint recognition, and secure unlocking, is significantly boosting FPC shipments. The demand for FPCs in this sector continues to grow rapidly.

2. **Automotive Electronics as a Growth Driver**

The electrification, automation, and connectivity of vehicles are expected to drive an explosion in FPC usage in the automotive sector. Automotive electronics are poised to account for more than 50% of a vehicle’s total cost in the future.

3. **Wearable Devices Expanding Across Multiple Fields**

Wearables, such as smartwatches, fitness trackers, smart glasses, and medical devices, are becoming more prevalent in areas like health, entertainment, smart homes, and more. This market will likely continue to expand, with FPC playing a crucial role in their development.

4. **High-Frequency FPC Development**

As 5G technology advances with innovations like millimeter waves and Massive MIMO, high-frequency FPCs will find new growth opportunities, especially in telecommunications and related fields.

2. An FPC (Flexible Printed Circuit Board), or flexible circuit board, offers high reliability and exceptional flexibility compared to traditional rigid PCBs. It boasts characteristics such as high wiring density, lightweight construction, slim profile, and excellent flexibility.

3. COF (Chip on Film) is a soft film technology used to mount integrated circuits (ICs) onto flexible circuit boards. This method involves bonding chip carriers to flexible substrate circuits, achieving high-density configurations, reduced weight and volume, and facilitating straightforward and complete installation.

4. The COF flexible packaging substrate represents an advanced offshoot of FPC technology. It plays a crucial role during chip packaging by providing structural support, circuit connectivity, and insulation. It enhances chip protection, improves signal transmission rates and fidelity, ensures impedance matching, relieves stress, aids in heat dissipation, and enhances moisture resistance.

1. **FCCL Soft Copper Foil Substrate** (Flexible Copper Clad Laminate), also known as flexible copper clad, flexible copper clad, or soft copper clad, is a substrate used in FPC (Flexible Printed Circuit) processing.

In addition to its thin, light, and flexible nature, FCCL features a polyimide base film (PI film), providing excellent electrical and thermal properties, as well as superior heat resistance. FCCL is categorized into two types: the traditional three-layer soft board matrix (3L FCCL) and the newer two-layer soft board matrix (2L FCCL). These two types are manufactured differently, leading to distinct material properties.

2. In terms of application, the products made from the two types of FCCL serve different purposes. 3L-FCCL is typically used for large-scale soft board products, while 2L-FCCL is preferred for advanced soft board manufacturing, such as for soft cardboard, COF, and more.

PI film, or polyimide film, is a high-temperature resistant organic polymer film, known for its electrical grade insulation and heat resistance. It is highly elastic, has a low coefficient of expansion, and meets various electronic performance standards. As a specialized engineering material, electronic-grade PI film is unparalleled by other polymers. It offers excellent heat resistance, oxygen resistance, mechanical properties, electrical performance, and chemical stability, often being referred to as “gold film.”

3. Currently, the largest application of microelectronic PI film is in flexible copper-clad laminates (FCCL), which serve as key insulating substrates.

The Tpi PI carbonized film, produced through polymer sintering, is a deep-processing product of PI film. Its exceptional thermal and electrical conductivity, along with features like battery shielding and stealth capabilities, make it ideal for use in flexible semiconductor devices, heat-dissipating chips, flexible displays, and solar power generation systems.

4. **Current Market of FPCs**

The largest application of FPCs is in smartphones, accounting for over 40% of total output. Consumer electronics generally require 2-15 FPC products, with smartphones typically using 10-15, and leading models such as Apple’s reaching 16-18 FPCs. As smartphone technology continues to innovate—such as with dual-lens cameras, OLED screens, fingerprint recognition, and wireless charging—demand for FPC products is set to increase.

5. **Apple’s Role in FPC Innovation**

Apple plays a crucial role in driving global FPC technology forward. In 2010, the iPhone 4 introduced the use of multi-layer HDI (High-Density Interconnect) boards, marking the start of the mobile phone industry’s lightweight transition. By 2014, the iPhone 6’s fingerprint recognition technology paved the way for FPC’s role in mobile security. Subsequent iPhone models, such as the iPhone 7 with its dual-camera system and the iPhone X with OLED displays and wireless charging, have significantly expanded FPC’s application, generating new market opportunities.

Additionally, Apple remains the primary customer for the world’s six largest FPC manufacturers.

6. **Vertical Integration in the Flexible PCB Industry**

The flexible PCB industry exhibits a clear vertical division of labor. Leading companies in developed countries control core processes such as key material technology, raw material supply, product development, design, marketing, and branding. Meanwhile, production and assembly tasks are often outsourced to professional factories in developing nations, establishing a system of independent, specialized labor. This includes raw material production, substrate manufacturing, chip packaging, and template assembly.

7. **China’s Rapid Growth in FPC Manufacturing**

China’s FPC manufacturing industry has seen rapid growth, driven by industrial transfers and the expanding consumer electronics market. The domestic FPC market now exceeds 30 billion yuan, representing over 30% of the global industry share. Currently, around one-third of FPC manufacturing enterprises in mainland China are foreign-invested, accounting for approximately 80% of the total output value.

8. **Future Application Trends**

1. **Smartphone Evolution Drives FPC Demand**

The continuous advancement of smartphones, especially in features like mobile payment, fingerprint recognition, and secure unlocking, is significantly boosting FPC shipments. The demand for FPCs in this sector continues to grow rapidly.

2. **Automotive Electronics as a Growth Driver**

The electrification, automation, and connectivity of vehicles are expected to drive an explosion in FPC usage in the automotive sector. Automotive electronics are poised to account for more than 50% of a vehicle’s total cost in the future.

3. **Wearable Devices Expanding Across Multiple Fields**

Wearables, such as smartwatches, fitness trackers, smart glasses, and medical devices, are becoming more prevalent in areas like health, entertainment, smart homes, and more. This market will likely continue to expand, with FPC playing a crucial role in their development.

4. **High-Frequency FPC Development**

As 5G technology advances with innovations like millimeter waves and Massive MIMO, high-frequency FPCs will find new growth opportunities, especially in telecommunications and related fields.