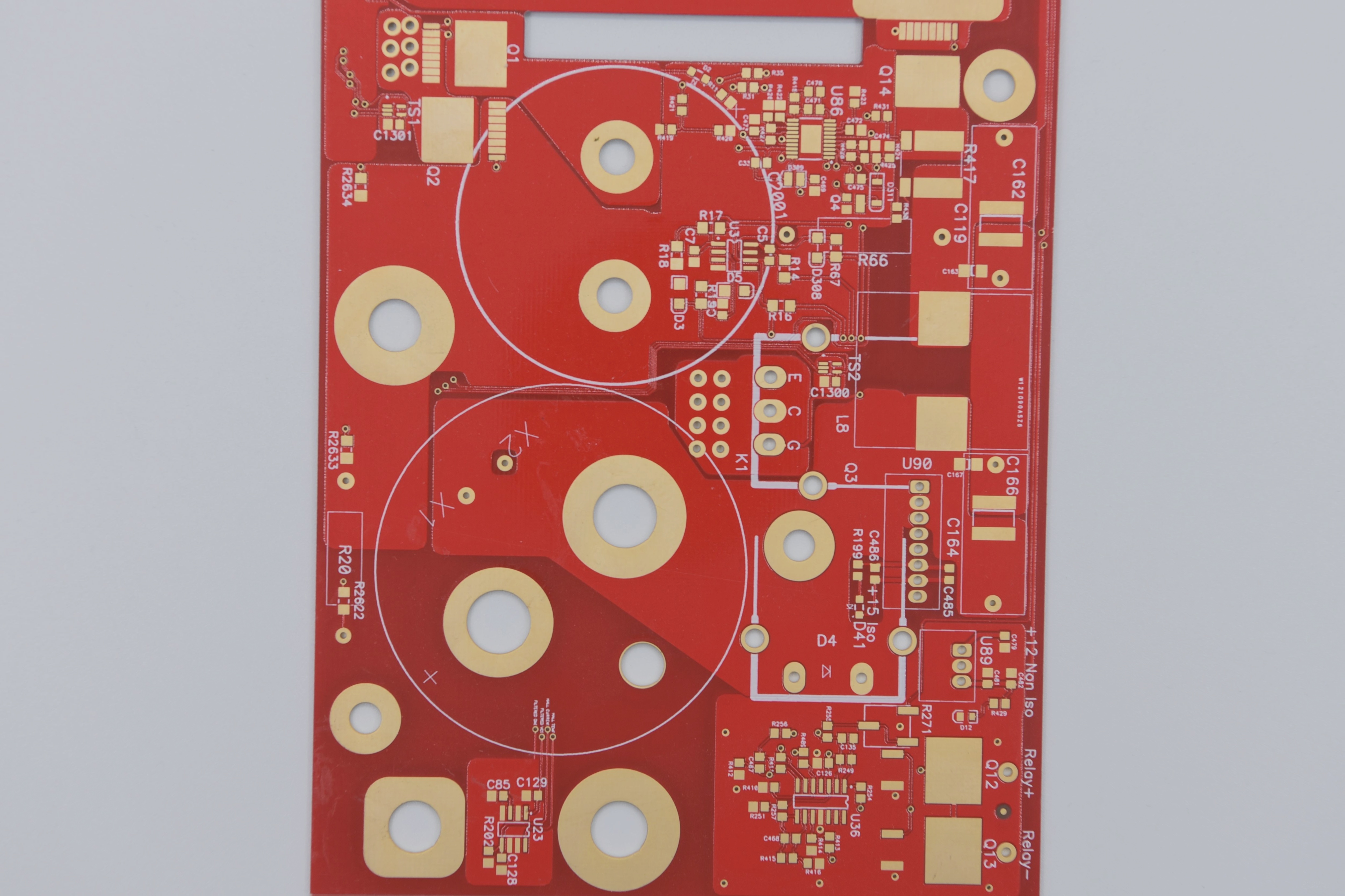

Environmental Impact of Discarded Printed Circuit Boards (PCBs)

With the continuous advancement of electronic technology, the disposal of printed circuit boards (PCBs) has become a growing concern. PCBs, which contain heavy metals like lead and mercury, as well as toxic substances such as polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE), pose a serious threat to the environment due to the pollution they cause. These contaminants can contaminate groundwater and soil, endangering human health.

Recycling Methods for Waste Circuit Boards

- Physical Law

- Crushing: Crushing waste circuit boards to a specific size allows for efficient separation of metals from organic materials.

- Sorting: Various technologies like wind shaker, flotation, cyclone separation, and eddy current separation are used to separate materials based on density, conductivity, and other properties.

Supercritical Technology Treatment Method

Supercritical fluid extraction technology offers a method to purify waste circuit boards without altering their chemical composition. By utilizing supercritical CO2, resin and metals can be efficiently extracted, allowing for effective material recycling.

Research on supercritical fluids focuses on extracting metals like Cd2+, Cu2+, and Zn2+ from waste circuit boards. While this method is effective, it has drawbacks such as high energy consumption and the need for specialized equipment.

Chemical Method for PCB Recycling

Chemical treatment technologies leverage the differences in chemical stability among PCB components for extraction.

Heat Treatment Method

- Incineration: Organic components are decomposed through incineration, leaving behind metals and glass fiber for recovery.

- Cracking Method: Utilizing high temperatures to separate organic matter from metals.

Pyrolysis for Electronic Waste Recycling

Pyrolysis, also known as dry distillation, involves heating electronic waste in a controlled environment without oxygen. This process decomposes organic materials into oil and gas, which can be collected. Unlike traditional incineration methods, vacuum pyrolysis minimizes the formation of harmful substances like dioxins and furans, reducing environmental impact.

Microwave Processing Technology

The microwave method starts with crushing electronic waste and then using microwave heating to break down organic materials. Heating up to 1400 degrees Celsius melts glass fiber and metal, creating a vitrified substance. After cooling, valuable metals like gold and silver can be separated, while leftover glass can be reused in construction. This technology stands out for its efficiency, quick processing, high resource recovery, and low energy consumption.

Hydrometallurgy for Metal Extraction

Hydrometallurgy utilizes acidic solutions like nitric acid and sulfuric acid to dissolve and recover metals from e-waste. This method is widely used due to its benefits, including reduced emissions, easier disposal of residues, economic advantages, and a straightforward process.

Biotechnology for Metal Recovery

Biotechnology uses microorganisms to adsorb metals on mineral surfaces and aid in metal recovery. This process involves microbial metabolites immobilizing metal ions or direct immobilization by microbes. While this approach offers advantages like simplicity and cost-effectiveness, it currently faces challenges such as longer leaching times and lower leaching rates.

Conclusion: Recycling PCBs for a Sustainable Future

Exploring metal recycling technologies for e-waste is crucial for both the economy and the environment. With the complexity of electronic waste, a combination of technologies is necessary for effective metal recovery. Future developments should focus on large-scale processing, maximizing resource recycling, and advancing processing methods. Recycling PCBs not only helps in environmental protection and resource conservation but also contributes to sustainable economic and social development.