The Evolution of PCBA MCM Technologies in Various Industries

- Alternative PCBA MCM technologies offer cost, size, and weight reduction, strong environmental adaptability, and enhanced performance with fewer interfaces.

- COB technology provides a cost-effective solution in scenarios where PCBA MCM technology is expensive.

- Handheld calculators in consumer electronics commonly utilize COB technology for cost efficiency.

- PCBA MCM technology reduces overall system costs through decreased PCB size and assembly costs.

- PCBA MCM technology is crucial in aerospace and military applications, especially in spacecraft design.

- Notebook computer manufacturers are increasingly adopting PCBA MCM-L technology for improved performance.

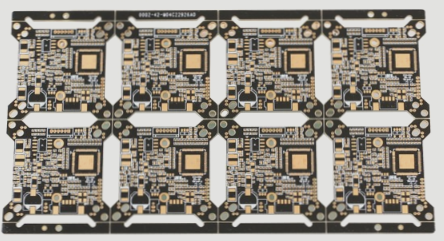

- Ceramic hybrid circuit packaging is widely used in harsh environments like automotive electronics.

- Ceramic packages are preferred for applications requiring isolation from the external environment.

Market Trends and Innovations in PCBA MCM Technology

- PCBA MCM technology is utilized in high-performance telecommunications, data processing, network equipment, and devices requiring high speed and multiple interfaces.

- Continuous performance improvements in low-end systems and multi-processor applications are driving the adoption of PCBA MCM technology in the electronic packaging market.

- PCBA MCM addresses size, cost reduction for low-end products, and size reduction, performance enhancement for high-end products.

- The European PCBA MCM market has shown significant growth, reaching 4 billion USD in 2002 and expected to expand to 10 billion USD by 2007.

- Advancements in design, packaging technology, and materials have reduced the cost of PCBA MCM, making it more accessible internationally.

- Various PCBA MCM types have adopted different single-chip packaging technologies, leading to reduced packaging costs.

Technical Aspects of PCBA MCM Manufacturing

- Sputtered multilayer aluminum interconnection layers in PCBA MCM typically range from 1 to 3 microns in thickness.

- BCB polymer dielectric layers provide stability at THz frequencies and are commonly used in wafer-level chip size packaging.

- PCBA MCMs undergo reliability assessments, including temperature cycles and testing, with a high pass rate, ensuring top-tier quality.

- Equipment investment and production capacity for PCBA MCMs are comparable to single-chip ICs, making them a feasible option for various applications.

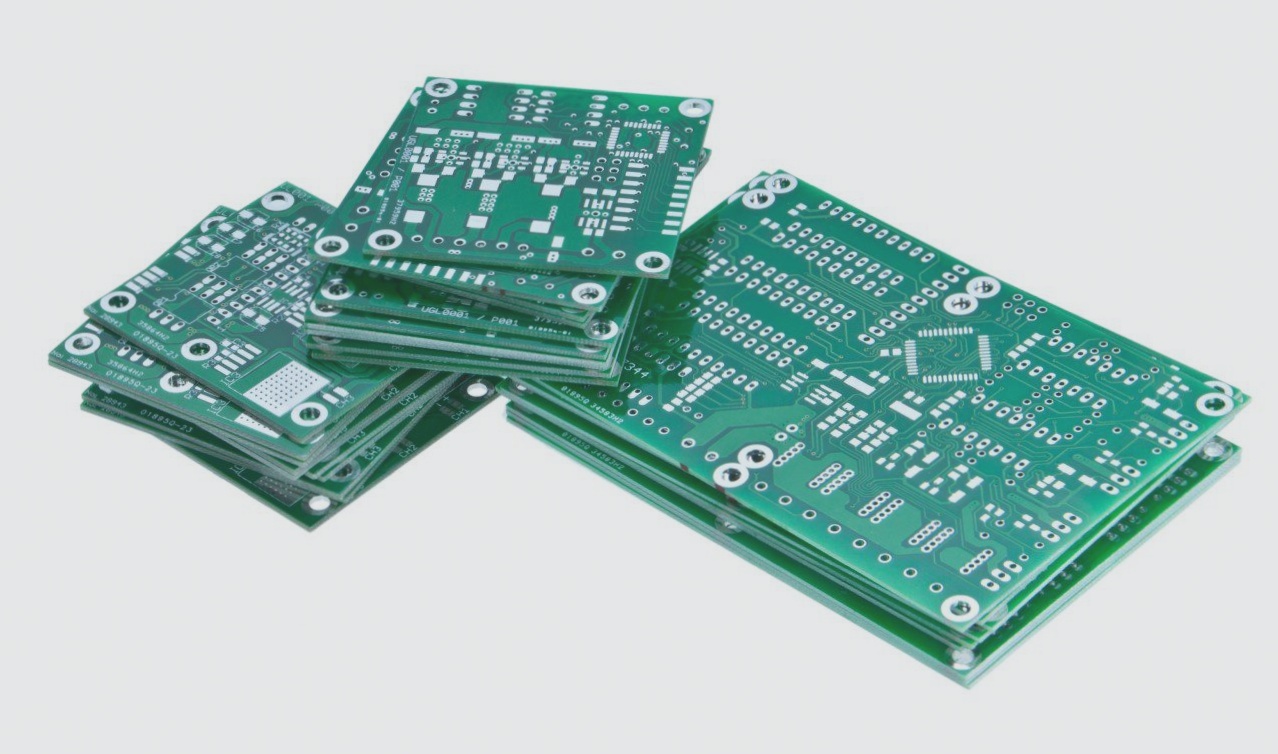

Advanced Packaging Processes for PCBA MCM

Manufacturers of PCBA MCM are implementing innovative packaging processes to enhance the quality of their products. One such method involves creating lead frames with unique structures to improve thermal endurance, especially for larger chips and packages. By carefully selecting materials, the BGAPCBA MCM-L can withstand thermal shock levels similar to those experienced by single-chip PQFPs.

Cost-Effective Packaging Solutions for PCBA MCM

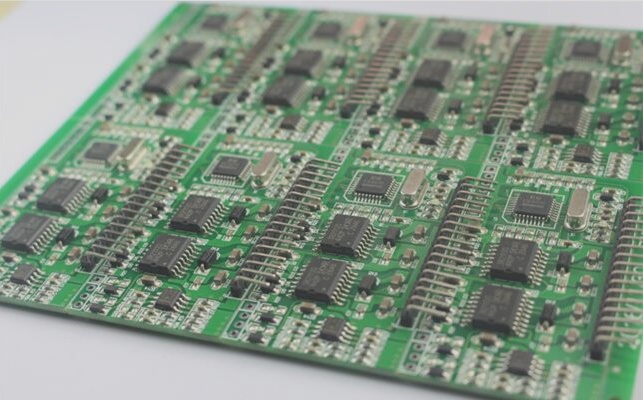

Reducing packaging costs is a key consideration for PCBA MCM production. Choosing the right packaging method is essential for cost efficiency. Some common packaging methods suitable for mass production include:

- Assembly after plastic packaging: Offers low cost and easy assembly

- Overall plastic package: Ideal for mass production scenarios

- COB package: Combines bare chips and surface mount components

- Metal package: Provides durability in harsh environments, albeit at a higher cost

- Ceramic package: Known for high performance

Optimal Packaging for Mass Production

The overall plastic packaging method is widely adopted by manufacturers of PCBA MCM for its suitability in mass production environments.