1.0 Introduction

The screen printing process in PCB manufacturing can encounter various faults, leading to issues with the printing material and the overall screen printing process. This article aims to identify the causes of these failures and provide appropriate countermeasures.

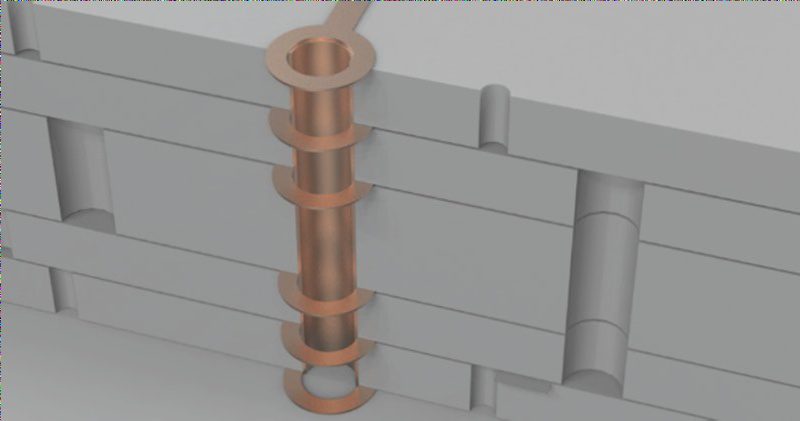

1.1 Plugging Holes

One common issue arises when using a new screen for the first time, where printing material may be of poor quality due to plate issues or residual glue on the mask. Scrubbing the screen with a solvent can eliminate the residual glue. If the problem persists, remaking the screen may be necessary. Additionally, if the printing material coating becomes thinner and pitted during the process, it may be due to excessive drying or blockage of the holes. Adjusting the printing material with a slow-volatility solvent and gentle scrubbing of the screen can help mitigate this issue.

1.2 Screen Ink Leakage

During screen printing, ink leakage onto the printed board can occur due to dust or debris on the board or the printing material, screen damage from the scraper pressure, insufficient exposure of the glue, or screen mask defects. Taping over the screen holes or using screen glue for repair can address this problem.

1.3 Broken Screen and Reduced Accuracy

Long-term use of the screen can lead to wear and reduced accuracy due to printing pressure, impacting the screen’s lifespan. Different methods of making the screen affect its durability, with direct method screens typically lasting longer. Proper maintenance and consideration of environmental factors can help prolong the life of the screen.

1.4 Failure Caused by Excessive Printing Pressure

Excessive printing pressure can result in issues such as the bending and deformation of the squeegee, poor image quality, and screen wear. Controlling the printing pressure based on screen tension, squeegee length, and screen distance is crucial to achieving optimal results in screen printing.