TU-662

Mid-Tg and High Thermal Reliability Laminate and Prepreg

Core: TU-662; Prepreg: TU-66P

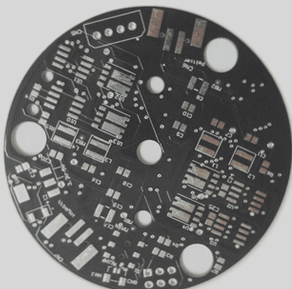

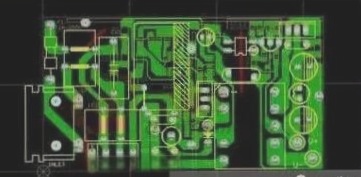

TU-662/TU-66P laminate/prepreg is made from high-quality woven E-glass coated with an epoxy resin system. This composition gives the laminate UV-blocking properties and compatibility with Automated Optical Inspection (AOI) processes. These products are ideal for applications requiring excellent thermal cycle resistance or enduring excessive assembly work. TU-662 laminates offer outstanding coefficient of thermal expansion (CTE), excellent chemical resistance, and thermal stability suitable for lead-free soldering assembly with general CAF resistance.

Main Applications

- Automotive

- Consumer Electronics

Key Features

- Lead-free process compatible

- Excellent coefficient of thermal expansion

- Anti-CAF property

- Compatible with FR-4 processing conditions (oxide, press, drilling, and desmear)

- Superior chemical and thermal resistance

- Fluorescent for AOI

- UV-block optical characteristics

- High interlayer bonding strength with optimal resin flow

- Low moisture absorption

Material Properties

| Property | Typical Values |

|---|---|

| Tg (DMA) | 160°C |

| Tg (DSC) | 150°C |

| Tg (TMA) | 140°C |

| Td (TGA) | 340°C |

| CTE z-axis (50 to 260°C) | 3.2% |

| T-260/T288 | >60 min / >10 min |

| Permittivity (RC 50%) @1GHz | 4.3 |

| Loss Tangent (RC 50%) @1GHz | 0.014 |

Industry Approvals

- IPC-4101 Type Designation: /21, /98, /99, /101

- UL Designation – ANSI Grade: FR-4.0

- UL File Number: E189572

- Flammability Rating: 94V-0

- Maximum Operating Temperature: 130°C

Standard Availability

- Thickness: 0.002” [0.05mm] to 0.062” [1.58mm], available in sheet or panel form

- Copper Foil Cladding: 1/3 to 6oz (HTE) for built-up; 1/3 to 3oz (HTE) for double sides; H to 2oz (MLS)

- Prepregs: Available in roll or panel form

- Glass Styles: 106, 1080, 2113, 2116, 1506, and 7628, etc.

If you have any questions about PCB and PCBA, please contact me at info@wellcircuits.com.