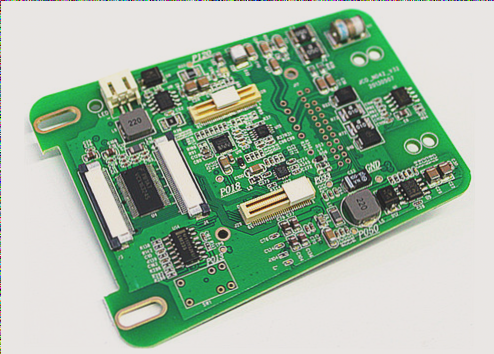

Troubleshooting Component Placement Issues in PCB Assembly Machines

Are you facing challenges with component placement in your PCB assembly machine? You’re not alone. Many users encounter issues with components being slightly off position or rotated during the assembly process. One common solution is to enable the machine’s auto fiducial recognition feature.

When loading the board, the machine may prompt you to calibrate to three components. This step is crucial for ensuring accurate placement, especially after the solder paste has been applied. However, it can sometimes require manual tweaking, leading to soldering problems like insufficient points or shorts.

If you’ve tried the two-point setup method without success, don’t worry. There are tips and tricks to help you get your machine up and running smoothly. Stay tuned for expert advice on optimizing component placement in your PCB assembly process.