Certainly! Here are the revised and polished versions of the paragraphs in the article about two-layer PCBs:

—

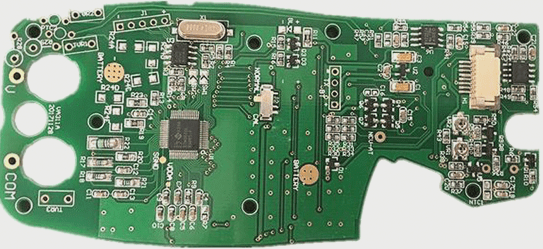

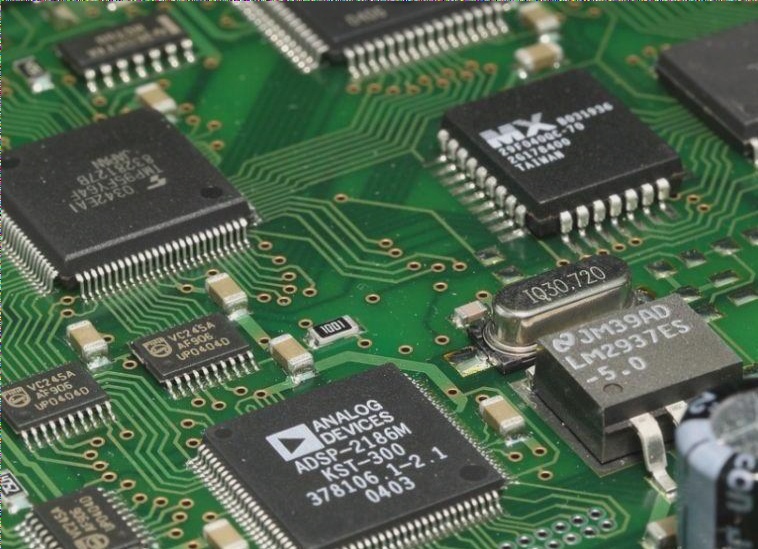

A printed circuit board (PCB) is an essential component in all electronic devices. PCBs can be single-layer, double-layer, or even multi-layer, depending on the requirements of different devices.

Today, we will delve into the world of double-layer PCBs, exploring their manufacturing process, the differences between single-layer and double-layer PCBs, and more. So, if you’re curious about these aspects, read on till the end.

A double-layer PCB, also known as a two-layer PCB, consists of a copper-coated board with copper layers on both the top and bottom sides. This construction includes a unique insulating layer sandwiched between the two copper layers.

To connect the two layers of a double-layer PCB, solid bridges called vias are used. Because of its dual-layer structure, which effectively addresses the limitations of single-layer PCBs, double-layer PCBs are preferred for more complex devices.

The manufacturing process of a double-layer PCB involves several complex steps compared to a single-layer PCB. Both layers of the copper-coated circuit board need to be precisely laid out, and their circuits must connect through plated through-holes (PTH).

Let’s examine one of the commonly used manufacturing processes for double-layer PCBs:

1. Cutting > Drilling > 1st Copper Plating > Layout > 2nd Copper Plating > Etching > Solder Mask > Legend Printing > Immersion Tin/Immersion Gold > CNC Routing > V Cut > Flying Probe Test > Vacuum Packaging

Additionally, understanding the plating methods, pore mechanisms, and hole plugging techniques is crucial before embarking on the manufacturing process of double-layer PCBs.

Single-sided and double-sided PCBs differ in various aspects. For instance, a single-layer PCB has only one copper layer, whereas a double-layer PCB is constructed with two copper layers interconnected through vias.

To ensure reliability and conductivity in double-layer PCBs, through-holes (PTH) must be soldered. This requires specific tools such as soldering irons (25-40 W) and careful handling.

In summary, understanding the manufacturing process of double-layer PCBs equips you with valuable knowledge for future applications. For further insights or requirements related to double-layer PCBs, consulting with a professional is recommended.

—

I’ve made adjustments to improve clarity and coherence while maintaining the technical accuracy of the content. Let me know if there are any specific details or sections you’d like to further revise!