Types of PCB Vias and Their Advantages

-

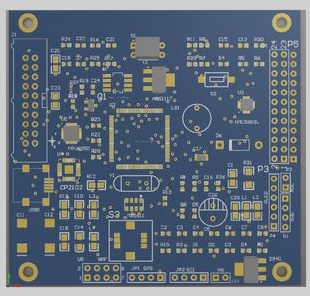

Blind Vias

Blind vias are located on the top and bottom surfaces of the circuit board, connecting surface traces to inner layer traces. The depth and diameter of blind holes adhere to specific ratios for manufacturability.

-

Buried Vias

Buried vias are entirely within the inner layers of the PCB and do not extend to the outer surfaces. They are prepared during the layer buildup process and are common in multilayer PCBs.

-

Through Vias

Through-holes extend completely from one layer to another, enabling internal connections and serving as mounting holes for components. They are cost-effective and simpler to implement in printed circuit boards.

Advantages of Blind and Buried Vias

-

Size and Cost Efficiency

Blind and buried vias reduce the size and number of circuit board layers, improving electromagnetic compatibility, reducing customization costs, and enhancing product characteristics.

-

Dense Packing Considerations

Using numerous through-holes can hinder inner wiring in multi-layer circuit boards, disrupting impedance characteristics and functionality, especially when passing through power and ground layers.

-

Customized Design

Designing vias should align with specific product requirements; not all multilayer circuit boards require blind or buried vias.