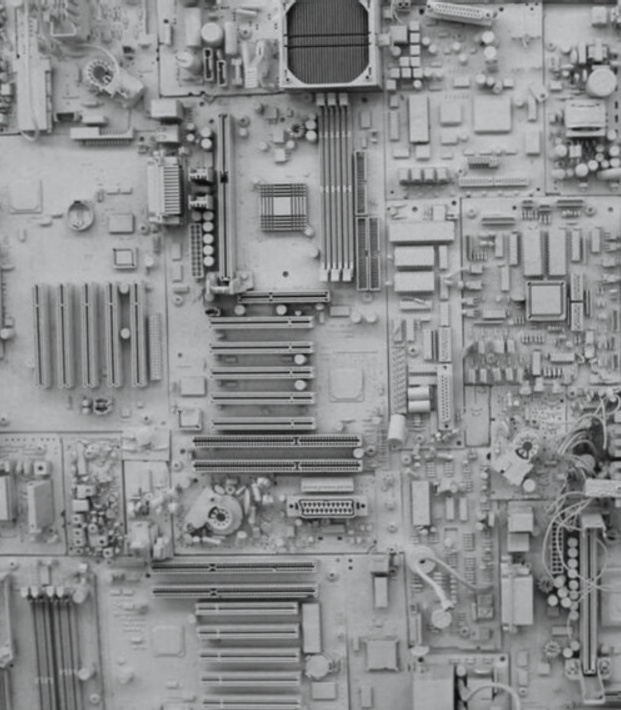

PCB tin spraying, also known as “hot air leveling”, is a crucial process in PCB board production. This process includes lead tin spraying and lead-free tin spraying, both of which are commonly used. Let’s explore the characteristics and basic knowledge of PCB spray tin types below.

Characteristics of PCB Surface Treatment Spray Tin:

Tin spraying is the most widely used process in PCB board manufacturing due to its practicality. It offers good soldering performance, oxidation resistance, and affordable pricing, making it a cost-effective choice. There are two main distinctions in PCB circuit board spray tin: lead and lead-free.

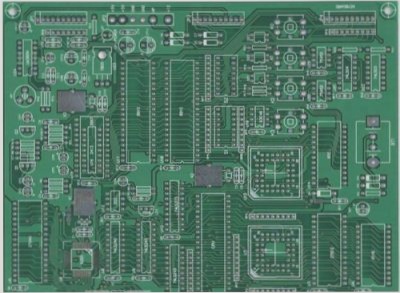

Types of PCB Surface Treatment Spray Tin:

1. Lead Spray Tin

Lead-sprayed tin involves adding lead to the tin in a specific proportion to enhance the tin wire’s activity during soldering. While lead-tin wire performs better than lead-free tin wire, lead is toxic and can be harmful to human health. The eutectic temperature of lead is lower than that of lead-free tin, and the eutectic temperature depends on the composition of the lead-free alloy. Lead also provides better mechanical strength and brightness than lead-free tin. However, the environmental impact of lead makes lead-free tin spray a preferable option.

2. Lead-Free Tin Spray

Lead-free tin spray is an environmentally friendly process with minimal harm to humans, making it a recommended choice. The lead content in lead-free tin does not exceed 0.5, and it has a higher melting point, resulting in stronger solder joints. Lead-free tin spray is safer for humans and the environment, positioning it as a future development trend.

By comparing the characteristics and drawbacks of lead spray tin and lead-free tin spray, it is evident that lead-free tin spray is the preferred choice due to its non-toxic and environmentally friendly nature.

WellCircuits Limited specializes in manufacturing high-precision double-sided, multi-layer, impedance, blind buried vias, and thick copper circuit boards. Our product range includes HDI, thick copper, backplanes, rigid-flex combinations, buried capacitance, buried resistance, Golden Finger, and other types of circuit boards to cater to diverse customer needs.

Characteristics of PCB Surface Treatment Spray Tin:

Tin spraying is the most widely used process in PCB board manufacturing due to its practicality. It offers good soldering performance, oxidation resistance, and affordable pricing, making it a cost-effective choice. There are two main distinctions in PCB circuit board spray tin: lead and lead-free.

Types of PCB Surface Treatment Spray Tin:

1. Lead Spray Tin

Lead-sprayed tin involves adding lead to the tin in a specific proportion to enhance the tin wire’s activity during soldering. While lead-tin wire performs better than lead-free tin wire, lead is toxic and can be harmful to human health. The eutectic temperature of lead is lower than that of lead-free tin, and the eutectic temperature depends on the composition of the lead-free alloy. Lead also provides better mechanical strength and brightness than lead-free tin. However, the environmental impact of lead makes lead-free tin spray a preferable option.

2. Lead-Free Tin Spray

Lead-free tin spray is an environmentally friendly process with minimal harm to humans, making it a recommended choice. The lead content in lead-free tin does not exceed 0.5, and it has a higher melting point, resulting in stronger solder joints. Lead-free tin spray is safer for humans and the environment, positioning it as a future development trend.

By comparing the characteristics and drawbacks of lead spray tin and lead-free tin spray, it is evident that lead-free tin spray is the preferred choice due to its non-toxic and environmentally friendly nature.

WellCircuits Limited specializes in manufacturing high-precision double-sided, multi-layer, impedance, blind buried vias, and thick copper circuit boards. Our product range includes HDI, thick copper, backplanes, rigid-flex combinations, buried capacitance, buried resistance, Golden Finger, and other types of circuit boards to cater to diverse customer needs.