PCBA Processing Machinery Overview

-

Printing Machine

The printing machine is a crucial component at the beginning of the PCBA processing line. It is responsible for applying solder paste or adhesive onto PCB circuit boards. By aligning the stencil mesh with the PCB pads, the solder paste or adhesive is transferred onto the board, preparing it for the next stage of component placement.

-

Dispenser

The dispenser applies solder paste or adhesive with precision. By dispensing the required amount onto the designated area of the PCBA device, it eliminates the need to change production fixtures, reducing production time significantly. This makes it ideal for small batches and diverse product runs.

-

Mounter (Placement Machine)

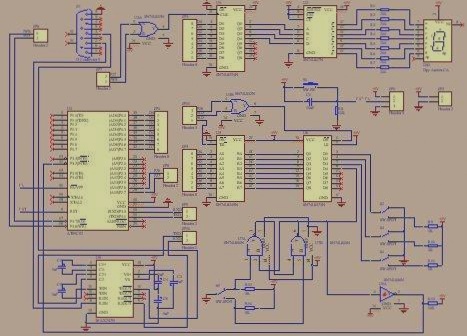

The mounter, also known as the placement machine, is the heart of PCBA processing. Its primary function is to pick materials accurately based on pre-set criteria and place them correctly at specified sites. The speed and accuracy of the mounter are crucial for efficient and precise PCBA processing.

-

Reflow Soldering Machine

The reflow soldering machine creates a stable heating environment to melt the pre-applied solder on the PCB, ensuring reliable adhesion between surface mount components and PCB pads.

-

Testing Equipment

Testing equipment, including X-ray detectors, magnifying glasses, microscopes, and automatic optical inspection devices, assesses the assembly quality and integrity of mounted PCBA products. These tools are crucial for ensuring the functionality and reliability of the final products.

-

Repair Equipment

Repair equipment, such as BGA rework stations and soldering irons, is used to fix identified faults in finished PCBA products. These tools are essential for maintaining product quality and reliability.

-

Cleaning Equipment

Cleaning equipment, like ultrasonic cleaning machines, removes substances that may affect the electrical properties of processed PCBA products. It is crucial for ensuring the cleanliness and integrity of the final products.

PCBA processing has evolved significantly with advancements in machinery and manufacturing techniques, leading to higher yields and improved efficiency in producing electronic products. The integration of sophisticated equipment and technologies has revolutionized the electronic manufacturing sector, making PCBA processing more precise and reliable than ever before.

For more information on PCBA processing and equipment, visit Well Circuits.