IPC was originally known as the “Printed Circuit Board Association” in the United States and later renamed as the “Electronic Circuit Interconnection and Packaging Association.” Due to its widespread popularity, the acronym IPC has consistently been used, eventually becoming the official name. “International Electronic Industry Connection Association” serves as an expansion to the association’s name.

IPC has developed numerous standards and specifications crucial to the electronic manufacturing industry. Some commonly referenced standards include:

Design Criteria:

– IPC-D-275 outlines design standards for rigid printed boards and their connections, categorized into levels A, B, and C based on precision, wiring density, and manufacturing complexity.

– IPC-SM-782 defines the standard for surface mount design pad graphics.

– IPC-SM-770 specifies printed board assembly requirements, covering surface mount and through-hole mounting design criteria.

Finished Product Design Documentation:

– IPC-D-325 serves as a document specification for customers to design circuit boards and propose assembly requirements for their products.

Production Site Standards:

– IPC-A-610 is a globally recognized quality inspection standard within the electronic manufacturing industry. Levels 2 and 3 often derive from IPC-A-610. This standard details the assembly and connection characteristics of printed circuit boards, exceeding general product requirements. It also delineates the structural forms of non-conforming components, aiding production personnel in promptly identifying and rectifying issues.

Product Classification:

– Level 1: General electronic products

– Level 2: Special service electronic products

– Level 3: High reliability electronic products

Higher levels necessitate more stringent quality inspection criteria, with IPC Level 3 commonly referred to as “industrial level.” The accompanying figure provides a reference for selecting a suitable standard.

IPC Level I

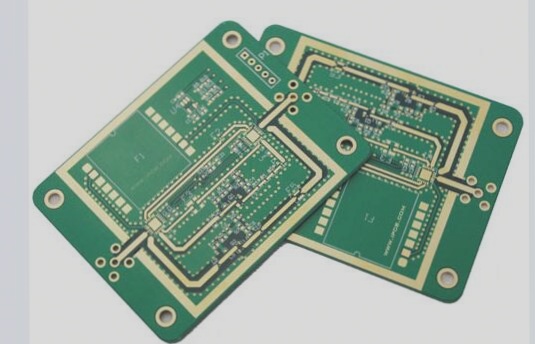

General electronic PCB products

The first level of electronic products is referred to as “general electronics.” These are typically used in products with short expected life cycles. For example, inexpensive toys may function normally when purchased for 20 yuan, but after a few months, they may fail to start when the power switch is activated. Such occurrences are often considered normal both by consumers and the manufacturers.

IPC Level II

Special service electronic PCB products

The second level includes electronic devices that require continuous performance and extended life cycles. These products demand uninterrupted service to avoid significant losses.

IPC Level III

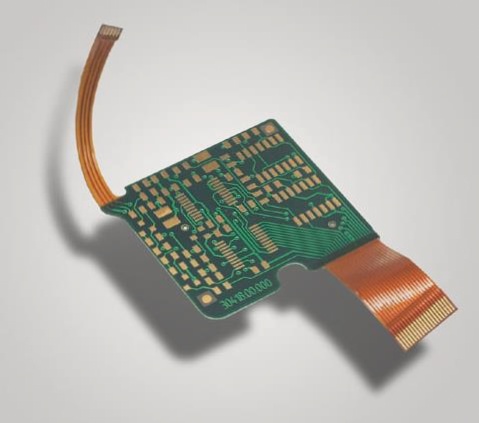

High-reliability electronic PCB products

This level encompasses equipment that operates continuously or under strict adherence to instructions. Examples include medical life support systems, flight control systems, precision measuring instruments, and other products used in harsh environments. Due to their critical nature, these PCBs must ensure no failures occur. The use of high-reliability components throughout the electronic system is crucial to maintain product stability and prevent irreversible damage in case of accidents.

IPC has developed numerous standards and specifications crucial to the electronic manufacturing industry. Some commonly referenced standards include:

Design Criteria:

– IPC-D-275 outlines design standards for rigid printed boards and their connections, categorized into levels A, B, and C based on precision, wiring density, and manufacturing complexity.

– IPC-SM-782 defines the standard for surface mount design pad graphics.

– IPC-SM-770 specifies printed board assembly requirements, covering surface mount and through-hole mounting design criteria.

Finished Product Design Documentation:

– IPC-D-325 serves as a document specification for customers to design circuit boards and propose assembly requirements for their products.

Production Site Standards:

– IPC-A-610 is a globally recognized quality inspection standard within the electronic manufacturing industry. Levels 2 and 3 often derive from IPC-A-610. This standard details the assembly and connection characteristics of printed circuit boards, exceeding general product requirements. It also delineates the structural forms of non-conforming components, aiding production personnel in promptly identifying and rectifying issues.

Product Classification:

– Level 1: General electronic products

– Level 2: Special service electronic products

– Level 3: High reliability electronic products

Higher levels necessitate more stringent quality inspection criteria, with IPC Level 3 commonly referred to as “industrial level.” The accompanying figure provides a reference for selecting a suitable standard.

IPC Level I

General electronic PCB products

The first level of electronic products is referred to as “general electronics.” These are typically used in products with short expected life cycles. For example, inexpensive toys may function normally when purchased for 20 yuan, but after a few months, they may fail to start when the power switch is activated. Such occurrences are often considered normal both by consumers and the manufacturers.

IPC Level II

Special service electronic PCB products

The second level includes electronic devices that require continuous performance and extended life cycles. These products demand uninterrupted service to avoid significant losses.

IPC Level III

High-reliability electronic PCB products

This level encompasses equipment that operates continuously or under strict adherence to instructions. Examples include medical life support systems, flight control systems, precision measuring instruments, and other products used in harsh environments. Due to their critical nature, these PCBs must ensure no failures occur. The use of high-reliability components throughout the electronic system is crucial to maintain product stability and prevent irreversible damage in case of accidents.