Enhancing Flexible PCB Performance with PCB Stiffeners

PCB stiffeners play a crucial role in reinforcing and supporting flexible circuit boards, improving their durability and reliability. These supplementary components provide mechanical support, flexural resistance, thermal management, and protection for connection points, among other benefits.

Flexible PCBs often require additional rigidity in certain areas to withstand bending, flexing, and stress. PCB stiffeners address these challenges, making them essential for various applications.

Latest Updates: Recent advancements in PCB stiffener technology have focused on enhancing heat dissipation capabilities, improving material durability, and optimizing component alignment for better performance.

Advantages of PCB Stiffeners

- Mechanical Support: Enhances strength and rigidity, reducing bending and deformation.

- Flexural Resistance: Resists bending stress, ensuring stability and reliability.

- Improved Thermal Management: Aids in heat conduction and dissipation, preventing overheating.

- Protection of Connection Points: Safeguards delicate components against stress and damage.

- Supporting Additional Components: Simplifies installation of extra components, increasing functionality.

- Precise Alignment: Acts as positioning guides, minimizing assembly errors.

- Vibration and Resonance Mitigation: Minimizes interference and enhances signal integrity.

Types of PCB Stiffeners

Polyimide (PI) Stiffeners

Polyimide offers heat resistance and strong bond strength, ideal for various applications.

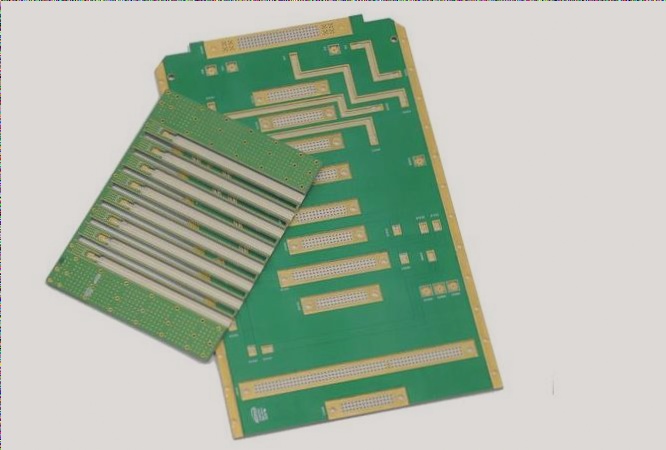

FR-4 Stiffeners

FR-4 provides flat support during assembly processes, reducing costs and simplifying assembly.

Stainless Steel or Aluminum Stiffeners

High-performance options for formability, corrosion resistance, and durability in flexible PCB designs.

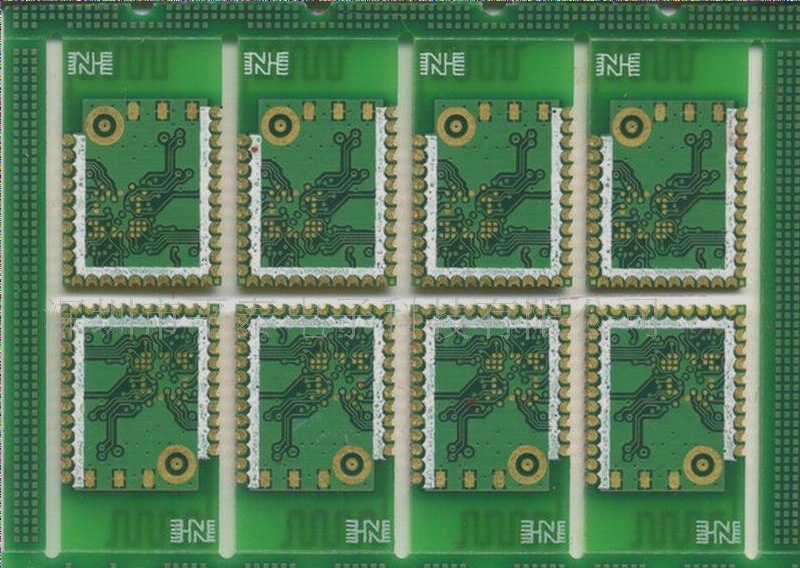

Placement of Stiffeners in Flexible PCBs

The Latest in Flexible PCB Stiffener Placement

- Stiffeners on the Top Layer

- Stiffeners on the Bottom Layer

- Stiffeners on Both Top and Bottom Layers

Top-layer stiffeners provide structural support to the flexible PCB, distributing weight evenly and ensuring balance, especially useful for components like LED displays.

Bottom-layer stiffeners enhance strength in specific areas, preventing long-term damage in sections with active components that require more support.

Using stiffeners on both layers increases rigidity and strength, crucial for critical areas of the PCB and applications with varying mechanical stresses.

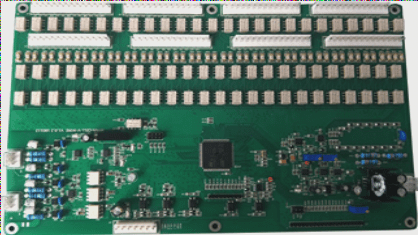

Enhancing Structural Integrity

In certain scenarios, stiffeners on both sides of a flexible PCB are essential for improving overall structural integrity, especially in applications with diverse mechanical stresses. Multi-layer stiffener designs offer greater stability, making them suitable for varying temperature ranges, vibrations, and impacts.

Attachment Methods for Stiffeners

Two primary methods for attaching stiffeners to a flexible PCB are Thermal Bonding and Pressure-Sensitive Adhesive (PSA). Each method has unique characteristics, with thermal bonding providing a stronger mechanical connection and PSA offering a simpler, more cost-effective solution.

If you have any inquiries regarding PCBs or PCBA, feel free to reach out to us at info@wellcircuits.com