Designing PCBs involves several challenges, such as undesirable breakouts caused by drill wander, misalignment, and stress concentration. One effective solution to mitigate these issues is the use of teardrops.

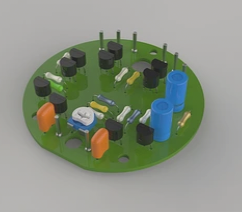

PCB teardrops are design features where the junction between a trace, pad, or via is tapered or gradually widened to form a teardrop-shaped connection. In some cases, teardrops may even resemble a snowman, with two rounded pads connected by a narrow trace in the middle. These teardrops add extra copper areas, ensuring smoother transitions and more evenly distributed stress. By improving both mechanical and electrical reliability, teardrops are especially useful in enhancing connections for through-hole pads and vias.

Functions of Teardrops in PCB Design

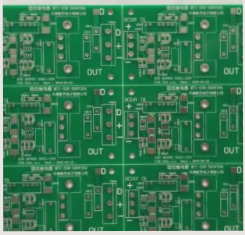

Minimize Undesirable Breakouts and Compensate for Misalignment

During the drilling of vias or holes in a PCB, slight deviations from the intended position can cause misalignment between the drilled holes and corresponding pads or traces. Teardrops help to address both hole and layer misalignment challenges. By incorporating teardrops, pads or traces gradually taper towards the drilled holes, creating a larger landing area for the drill bit. Furthermore, when vias or pads connect traces on different layers, the teardrop shape provides tolerance for any slight misalignment. This tapered design ensures a sufficient connection area is maintained, reducing the negative impact of misalignment on both the electrical and mechanical integrity of the connection.

Reduce Mechanical Stress and Enhance Reliability

Teardrops also play a crucial role in alleviating stress concentrations at connection points, particularly where thin traces meet pads or via annular rings. Issues such as solder joint fractures, pad lifting, or via cracking can arise in these areas. Teardrops help to prevent these issues by providing a smooth transition from a wider trace to a narrower neck. This gradual change in shape reduces stress concentrations and offers relief by eliminating abrupt geometric changes. Additionally, teardrops reinforce the structural integrity of through-hole pads and vias, enabling the PCB to better withstand environmental factors, temperature fluctuations, and physical stress, ultimately boosting its overall reliability.

Teardrops are especially important in specific applications such as flexible PCBs. The flexibility of these boards can create stress points, particularly where traces meet pads. By integrating teardrops into flexible PCB layouts, the traces and pads are better able to endure bending and flexing without suffering significant stress-related issues. Besides flexible PCBs, teardrops are also beneficial in high-speed designs, fine-pitch component layouts, and high-stress or high-density areas of the board.

If you have any questions about PCB or PCBA, please feel free to contact me at info@wellcircuits.com.