With the continuous advancement of electronic technology, the use of PCBs (Printed Circuit Boards) has become increasingly widespread. PCBs are essential components in electronic devices, playing a vital role across various applications. Among the different types of PCBs, Aluminum PCBs and FR4 PCBs (Glass Fiber Reinforced Epoxy Resin PCBs) are two of the most commonly used, with notable differences in materials, performance, and applications. Aluminum PCBs offer superior thermal conductivity compared to FR4 PCBs. This article will explore the key differences between Aluminum PCBs and FR4 PCBs in detail.

Materials

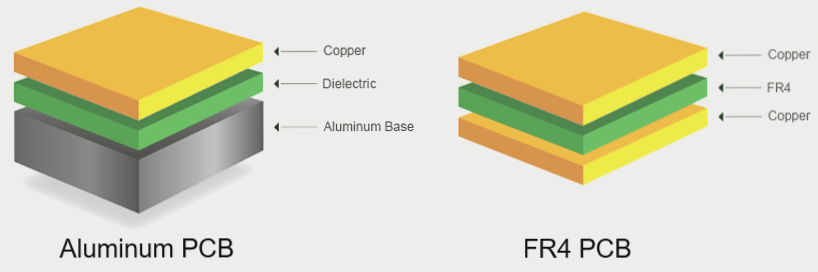

The name “Aluminum PCB” reveals its primary material—aluminum. Typically, it features an aluminum substrate, which provides excellent thermal conductivity for the PCB. An insulating layer is generally applied over the aluminum substrate to electrically isolate the circuit.

In contrast, FR4 PCBs are made from glass fiber-reinforced epoxy resin. This material offers excellent mechanical strength but has relatively poor thermal conductivity. The “FR” in FR4 stands for “Flame Retardant,” ensuring compliance with UL 94V-0 safety standards.

Thermal Conductivity

Aluminum PCBs are well-known for their superior thermal conductivity. Aluminum, being an excellent heat conductor, makes these PCBs ideal for applications that require efficient heat transfer and dissipation. For instance, LED lighting systems generate significant heat, and aluminum PCBs effectively manage this heat, improving the performance and lifespan of the LEDs. On the other hand, FR4 PCBs have relatively low thermal conductivity, which makes them unsuitable for applications where heat dissipation is critical. This is because FR4 is primarily made of glass fiber-reinforced epoxy resin, which does not efficiently conduct heat.

Coefficient of Thermal Expansion

Thermal expansion is a concern with FR4, particularly in the thickness direction of the board, as it can negatively impact the quality of metalized holes and circuit lines. The reason for this is the significant difference in the coefficient of thermal expansion (CTE) between copper and FR4 material: copper has a CTE of 17×10^-6 cm/cm℃, while FR4 has a much higher CTE of 110×10^-6 cm/cm℃. This large discrepancy can cause expansion mismatches between the base material and copper lines, leading to stress, cracking, and reliability issues in the PCB.

Aluminum substrates, with a CTE of 50×10^-6 cm/cm℃, offer a closer match to the CTE of copper foil. This similarity helps maintain the integrity and reliability of the PCB, making aluminum substrates an excellent choice when a lower coefficient of thermal expansion is required.

Laminating Layers

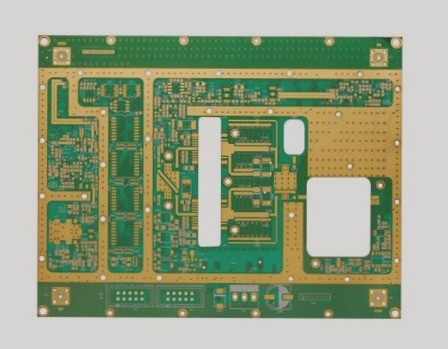

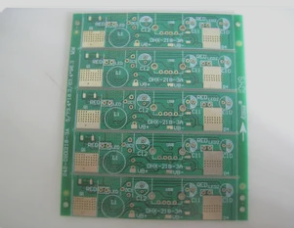

Aluminum PCBs are typically constructed with three layers: the aluminum substrate, a copper conductive layer, and a dielectric layer. These layers make aluminum PCBs especially suitable for high-temperature environments. In contrast, FR4 PCBs can be designed as single-layer, double-layer, or multi-layer boards, depending on the complexity of the circuit.

Mechanical Strength and Rigidity

Due to the metal core base, aluminum PCBs offer higher mechanical strength and rigidity compared to FR4 PCBs. For applications that require the PCB to support multiple electronic components, aluminum PCBs provide superior structural support. The aluminum substrate enhances the mechanical stability of the circuit, ensuring better performance under demanding conditions.

Thickness

In terms of thickness, FR4 PCBs generally offer a wider range of thickness options due to their ability to be multi-layered. However, aluminum PCBs have a more restricted thickness range, mainly due to the thickness of the dielectric and metal backing layer. The aluminum backing layer is typically thicker to aid in heat dissipation, which limits the overall thickness compared to FR4 boards.

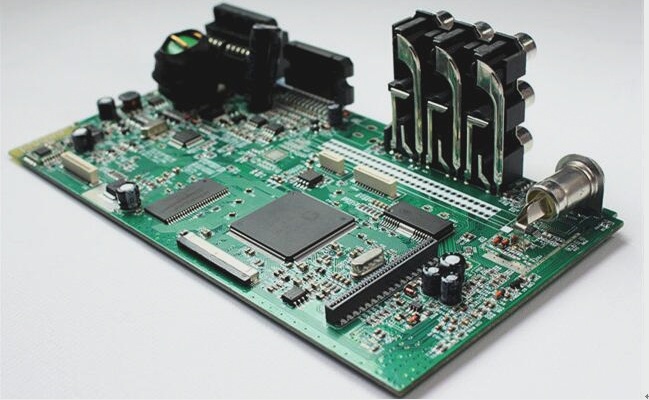

Applications

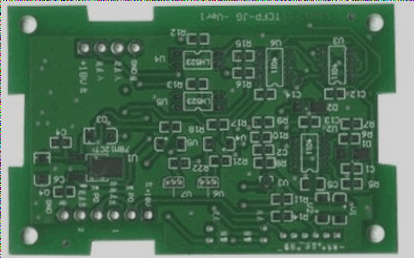

Each type of PCB is suited to different applications based on its unique properties. Aluminum PCBs are ideal for high thermal and electrical conductivity applications. Besides LED lighting, they are widely used in power modules, high-power RF applications, automotive electronics, and other high-performance systems. In contrast, FR4 PCBs are commonly used in everyday electronic circuits where thermal conductivity is less of a concern. The mechanical strength and electrical insulation properties of FR4 make it suitable for general-purpose electronics. For applications requiring better thermal resistance, high-TG (Glass Transition Temperature) FR4 variants are available, providing higher temperature stability for more demanding environments.

In conclusion, the differences between Aluminum PCBs and FR4 PCBs are substantial in terms of materials, thermal performance, coefficient of thermal expansion, lamination, mechanical strength, thickness, and suitability for specific applications. Selecting the appropriate PCB type for a given application is crucial for optimizing device performance and ensuring long-term reliability. Aluminum PCBs are the preferred choice for applications requiring efficient heat dissipation and electrical conductivity, while FR4 PCBs are typically used for general-purpose electronic circuits. By understanding these differences, engineers and designers can make informed decisions to meet the needs of their projects.

Furthermore, if your project requires PCBs with varying thicknesses, FR4 PCBs are the optimal choice. However, for applications requiring strong electromagnetic shielding and superior heat dissipation, aluminum PCBs are highly recommended.

If you have any questions regarding PCBs or PCBA, feel free to contact us at info@wellcircuits.com.