Introduction:

UL 94 is a safety standard established by Underwriters Laboratories (UL) to assess the flammability of plastic materials used in devices and appliances. It provides a classification system based on the material’s ability to resist ignition and sustain combustion when exposed to a small flame or ignition source. Flame-retardant thermoplastics, which are vital in industries such as electronics, automotive, and construction, undergo rigorous testing to meet UL 94 standards.

Test Methods

The UL 94 standard categorizes materials based on their flammability characteristics. Below are the test methods for the different classifications.

Horizontal Burn Test (HB)

This test involves clamping one end of the sample horizontally at an angle of 45±2 degrees. An iron mesh is placed horizontally beneath the sample, 10±1mm from it. A burner (with a flame height of approximately 20mm) is positioned at a 45-degree angle, 6mm from the other end of the sample, and the timer is started for 30±1 seconds. If the specimen reaches the 25mm mark within this time, another timer is started, and the burner is removed.

50W Vertical Flame Test

The burner (with a flame height of approximately 20mm) is placed at the center of the sample’s bottom side. It is ignited for 10±0.5 seconds before being removed at a speed of 300mm/s, ensuring it is at least 150mm away from the specimen. The time for the first spontaneous ignition is recorded. After the combustion stops, a second ignition is conducted, followed by another 10±0.5 seconds of flame exposure. The time of second spontaneous ignition and the time the specimen continues to glow after the flame is extinguished are noted.

500W Vertical Combustion Test

Step One

The specimen is fixed horizontally with a jig or fixture. The burner is positioned at the bottom of the specimen at an angle of 20±5 degrees from the horizontal. The flame tip touches the center of the specimen’s bottom, and the specimen is exposed to the flame for 5±0.5 seconds. The burner is then removed for 5±0.5 seconds. This procedure is repeated five times. After the fifth exposure, the specimen is removed, and any holes or damage in the material are observed and recorded.

Step Two

The burner (with a flame height of approximately 125mm) is placed at a 20±5 degree angle to the side of the specimen, with the inner part of the flame (40mm ± 2mm high) contacting the bottom side of the sample. The flame is applied for 5±0.5 seconds, then the burner is removed for 5±0.5 seconds. This cycle is repeated five times. After the fifth flame exposure, the time of spontaneous combustion and the time the specimen remains red after the flame is extinguished are recorded.

Advantages of UL 94 Compliance:

Adhering to UL 94 standards offers several key advantages for both manufacturers and consumers. First, it ensures the safety and reliability of products by minimizing the risk of fire hazards. Second, it enhances the marketability of products by demonstrating compliance with stringent safety standards. Additionally, UL 94 compliance may be a regulatory requirement in certain industries, especially those involving electronics, building materials, and transportation.

Materials with UL 94 Certification

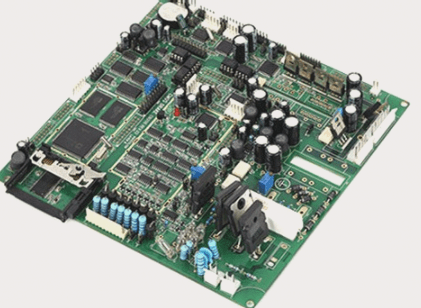

Currently, UL 94 certified injection molding materials include ABS, PC, ABS/PC, PP, PA, PEEK, and others. If you require UL 94 compliance for your product, you can specify it when placing an order, or contact mila@wellcircuits.com to select the most appropriate material for your needs.