Advantages of PCBs

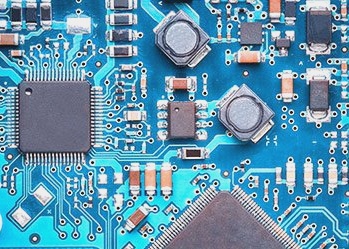

- High Density: PCBs have evolved with advancements in integrated circuit integration and mounting technology, allowing for high-density layouts.

- High Reliability: Rigorous inspections and tests ensure that PCBs can operate reliably for up to 20 years.

- Designability: PCB designs can meet various performance requirements efficiently through standardized processes.

- Manufacturability: Modern management approaches enable standardized, automated production processes for consistent quality.

- Testability: Established test methods and standards ensure accurate evaluation of PCB product eligibility and service life.

- Assemblability: PCBs allow for standardized component assembly, enabling automated and large-scale production.

- Maintainability: Standardized design and production processes facilitate quick part replacement for system restoration, along with system miniaturization and high-speed signal transmission capabilities.

Recent advancements in PCB technology have also focused on enhancing thermal management capabilities, improving signal integrity for high-speed applications, and incorporating eco-friendly materials for sustainable manufacturing practices.