What is aluminum nitride substrate:

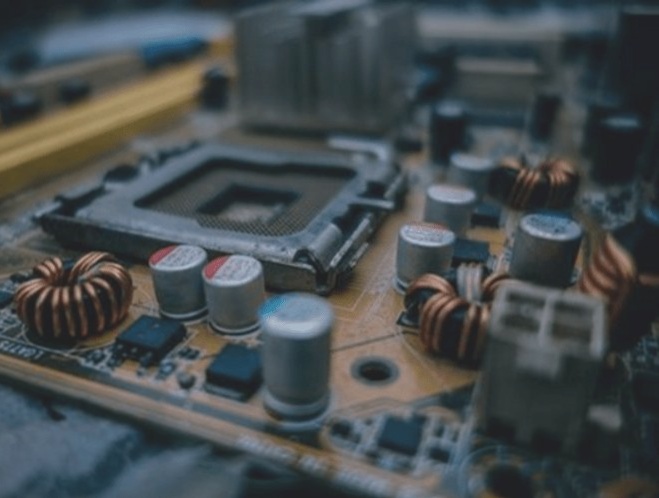

Aluminum nitride substrate refers to a ceramic material with aluminum nitride (AIN) as the main crystalline phase. Metal circuits are then etched onto the aluminum nitride substrate, making it the aluminum nitride ceramic substrate.

Aluminum nitride is known for its high thermal conductivity, making it a commonly used semiconductor material. Its high thermal conductivity and excellent electrical insulation performance make it an ideal material for sintered bodies. This makes it an excellent choice for semiconductors and a variety of other applications where heat dissipation is crucial.

Aluminum nitride ceramic is a versatile material with applications in high-temperature and high-power electronics, LED lighting technology, and general heat dissipation. Its durability and conductivity make it suitable for a wide range of uses in different industries, making it a common material in various applications.

Application of Aluminum Nitride Substrate:

1: Aluminum nitride as a substrate material

The substrate used for packaging not only needs to meet the basic requirements of high resistivity, high thermal conductivity, and low dielectric constant, but also needs to have good thermal matching with semiconductor materials such as silicon wafers, along with characteristics such as easy molding, high surface flatness, easy metallization, easy processing, low cost, and certain mechanical properties.

Aluminum nitride substrate has a series of excellent characteristics such as excellent thermal conductivity, reliable electrical insulation, low dielectric constant and dielectric loss, non-toxicity, and coefficient of thermal expansion matching with silicon. The thermal conductivity can reach 170W/(m • k), which is more than 5 times that of traditional substrate material alumina. Compared with other electronic grade ceramic materials, it is very suitable for insulation substrates of high-power devices, heat dissipation substrates of ultra-large scale integrated circuits, and packaging substrates from performance, cost, and environmental factors.

2: Aluminum Nitride for Deep UV LED Substrates

Aluminum nitride substrate can effectively alleviate stress accumulation during the epitaxial process, reduce epitaxial wafer defects, and significantly improve the performance and lifespan of deep ultraviolet LED devices. In addition to the general properties of wide band gap semiconductor materials such as large band gap (6.2 eV), high breakdown electric field strength, high thermal conductivity, and high chemical stability, aluminum nitride also has excellent ultraviolet light transmittance, making it an ideal material for preparing ultraviolet photoelectric product devices (such as purified water, disinfection, communication, sensors, medical treatment, and photolithography).

3: Aluminum nitride is widely used in thermal interface materials (TIM)

Thermal conductive silicone grease filled with high thermal conductivity particles such as aluminum nitride (AlN), also known as thermal conductive paste, has a certain fluidity and is a common traditional heat dissipation material with good thermal performance and a shorter manufacturing cycle; Low viscosity makes it easy to fill interface voids.

4: Aluminum Nitride as an Ultra High-Temperature Packaging Material

The melting point of aluminum nitride (AlN) is as high as 2500 ℃, making it suitable for high-temperature and heat-resistant materials. The coefficient of thermal expansion of aluminum nitride is similar to the coefficient of thermal expansion of Si and SiC. After thick film metallization, it can meet the requirements of temperatures up to 500 ℃ and a power density of 1000W/cm2. Aluminum nitride ceramic chip-level packaging can be applied to ultra-high-temperature (above 500 ℃) microelectronic devices.

5: Aluminum Nitride as a High-Power Device Material

In wireless transceiver systems, the solid-state amplification circuit of the transceiver module (TR module) uses a wide bandgap semiconductor power device with higher output power. Aluminum nitride (AlN) with high thermal conductivity can transfer internal heat to the heat sink, avoiding excessive internal temperature inside the module. TR components fully utilize the high thermal conductivity and strength characteristics of aluminum nitride substrates, adopting multi-layer high-temperature co-firing technology to solve the vertical interconnection of RF signals in high-density assembly of stacked structures, as well as issues such as heat dissipation and sealing.

6: Aluminum Nitride as a High-Frequency Device Material

Aluminum nitride can be used as a collector, clamp, and energy transfer window for microwave tubes. The dielectric loss of aluminum nitride can be as low as 10 ^ (-4). When the window heat is too high, it can effectively ensure the safety of electronic devices.

7: Aluminum nitride used as a thin film material

Aluminum nitride thin film material has good thermal stability and piezoelectric properties at high temperatures and can work in high-temperature environments close to 1200 ℃, making it a high-performance piezoelectric material. Aluminum nitride thin films can be applied in micro modules, sensors, integrated circuits, and active components.

Aluminum nitride (AlN) substrates have a series of excellent characteristics such as high thermal conductivity, high resistance, low dielectric loss, thermal expansion performance that matches semiconductor materials such as silicon, and good mechanical properties. Aluminum nitride electronic ceramics have become an important solution to the heat dissipation problem of highly integrated and miniaturized electronic devices, effectively ensuring the reliability and safety of electronic devices.

Aluminum nitride substrate refers to a ceramic material with aluminum nitride (AIN) as the main crystalline phase. Metal circuits are then etched onto the aluminum nitride substrate, making it the aluminum nitride ceramic substrate.

Aluminum nitride is known for its high thermal conductivity, making it a commonly used semiconductor material. Its high thermal conductivity and excellent electrical insulation performance make it an ideal material for sintered bodies. This makes it an excellent choice for semiconductors and a variety of other applications where heat dissipation is crucial.

Aluminum nitride ceramic is a versatile material with applications in high-temperature and high-power electronics, LED lighting technology, and general heat dissipation. Its durability and conductivity make it suitable for a wide range of uses in different industries, making it a common material in various applications.

Application of Aluminum Nitride Substrate:

1: Aluminum nitride as a substrate material

The substrate used for packaging not only needs to meet the basic requirements of high resistivity, high thermal conductivity, and low dielectric constant, but also needs to have good thermal matching with semiconductor materials such as silicon wafers, along with characteristics such as easy molding, high surface flatness, easy metallization, easy processing, low cost, and certain mechanical properties.

Aluminum nitride substrate has a series of excellent characteristics such as excellent thermal conductivity, reliable electrical insulation, low dielectric constant and dielectric loss, non-toxicity, and coefficient of thermal expansion matching with silicon. The thermal conductivity can reach 170W/(m • k), which is more than 5 times that of traditional substrate material alumina. Compared with other electronic grade ceramic materials, it is very suitable for insulation substrates of high-power devices, heat dissipation substrates of ultra-large scale integrated circuits, and packaging substrates from performance, cost, and environmental factors.

2: Aluminum Nitride for Deep UV LED Substrates

Aluminum nitride substrate can effectively alleviate stress accumulation during the epitaxial process, reduce epitaxial wafer defects, and significantly improve the performance and lifespan of deep ultraviolet LED devices. In addition to the general properties of wide band gap semiconductor materials such as large band gap (6.2 eV), high breakdown electric field strength, high thermal conductivity, and high chemical stability, aluminum nitride also has excellent ultraviolet light transmittance, making it an ideal material for preparing ultraviolet photoelectric product devices (such as purified water, disinfection, communication, sensors, medical treatment, and photolithography).

3: Aluminum nitride is widely used in thermal interface materials (TIM)

Thermal conductive silicone grease filled with high thermal conductivity particles such as aluminum nitride (AlN), also known as thermal conductive paste, has a certain fluidity and is a common traditional heat dissipation material with good thermal performance and a shorter manufacturing cycle; Low viscosity makes it easy to fill interface voids.

4: Aluminum Nitride as an Ultra High-Temperature Packaging Material

The melting point of aluminum nitride (AlN) is as high as 2500 ℃, making it suitable for high-temperature and heat-resistant materials. The coefficient of thermal expansion of aluminum nitride is similar to the coefficient of thermal expansion of Si and SiC. After thick film metallization, it can meet the requirements of temperatures up to 500 ℃ and a power density of 1000W/cm2. Aluminum nitride ceramic chip-level packaging can be applied to ultra-high-temperature (above 500 ℃) microelectronic devices.

5: Aluminum Nitride as a High-Power Device Material

In wireless transceiver systems, the solid-state amplification circuit of the transceiver module (TR module) uses a wide bandgap semiconductor power device with higher output power. Aluminum nitride (AlN) with high thermal conductivity can transfer internal heat to the heat sink, avoiding excessive internal temperature inside the module. TR components fully utilize the high thermal conductivity and strength characteristics of aluminum nitride substrates, adopting multi-layer high-temperature co-firing technology to solve the vertical interconnection of RF signals in high-density assembly of stacked structures, as well as issues such as heat dissipation and sealing.

6: Aluminum Nitride as a High-Frequency Device Material

Aluminum nitride can be used as a collector, clamp, and energy transfer window for microwave tubes. The dielectric loss of aluminum nitride can be as low as 10 ^ (-4). When the window heat is too high, it can effectively ensure the safety of electronic devices.

7: Aluminum nitride used as a thin film material

Aluminum nitride thin film material has good thermal stability and piezoelectric properties at high temperatures and can work in high-temperature environments close to 1200 ℃, making it a high-performance piezoelectric material. Aluminum nitride thin films can be applied in micro modules, sensors, integrated circuits, and active components.

Aluminum nitride (AlN) substrates have a series of excellent characteristics such as high thermal conductivity, high resistance, low dielectric loss, thermal expansion performance that matches semiconductor materials such as silicon, and good mechanical properties. Aluminum nitride electronic ceramics have become an important solution to the heat dissipation problem of highly integrated and miniaturized electronic devices, effectively ensuring the reliability and safety of electronic devices.