Improving PCB Quality with Upper and Lower Backing Pads

PCB (Printed Circuit Board) manufacturing requires precise drilling to maintain product quality. Utilizing upper and lower backing pads is crucial in preventing burrs and blooming during the drilling process, ultimately enhancing the PCB’s overall quality and yield rate.

Functions and Considerations of Backing Pads

- Backings must provide adequate hardness to prevent burrs without excessive wear on drill bits.

- Resin composition balance is crucial to avoid molten resin issues during drilling.

- High thermal conductivity aids in heat dissipation, preventing drill bit overheating.

- Rigidity and elasticity ensure precise alignment and drilling accuracy.

Materials for Backing Boards in PCB Drilling

Common materials in China include phenolic paper rubber sheets, epoxy glass cloth sheets, and aluminum foils like LF2Y2 and LF21Y. Aluminum foils offer superior rigidity, elasticity, and thermal conductivity, reducing drill breakage and hole irregularities.

Benefits of Aluminum Foil

- Excellent heat dissipation properties maintain optimal drilling temperatures.

- Prevents resin contamination during drilling, ensuring hole cleanliness.

- Available in various thicknesses, with 0.20mm being a balanced and commonly chosen option.

Investing in quality backing pads is essential for enhancing PCB manufacturing efficiency and product quality, despite the additional cost incurred.

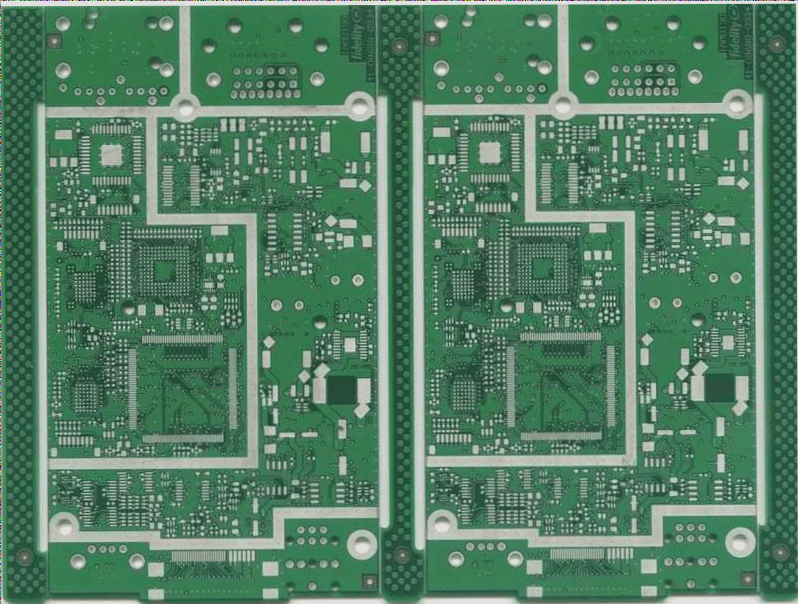

Composite Backing Boards for PCB Drilling

- Composite backing boards with 0.06mm aluminum alloy foil on the upper and lower layers

- Features a pure fiber core in the middle, totaling 0.35mm in thickness

- Designed for high-quality multilayer PCB drilling

- Advantages over traditional aluminum foil include superior drilling quality, precise hole positioning, longer drill bit life, and resilience

- Significantly lighter than aluminum foil, ideal for small hole drilling applications

Underlay Board Options for PCB Drilling

- Common options in China: phenolic paper boards, cardboard, and wood chip boards

- Cardboard: soft, prevents drill bit breakage, suitable for thin copper foil

- Wood chip boards: harder but poor texture uniformity, not ideal for thicker copper foils

- Phenolic paper boards: best hardness uniformity, reliable drilling results, more expensive

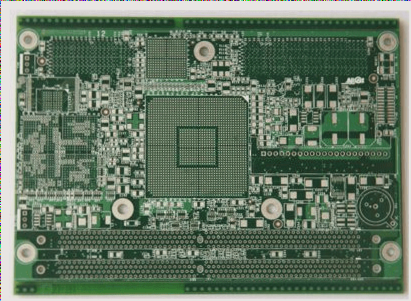

Composite Underlay Boards in International Markets

- Composite underlay boards with 0.06mm aluminum alloy foil on upper and lower layers, pure fiber core in the middle

- Total thickness of 1.50mm, exceptional performance for multilayer boards and small-diameter holes

- More environmentally friendly than phenolic paper boards but higher cost

Choosing the Right PCB Backing Material

Choosing the right backing material for PCB drilling involves balancing performance, cost, and environmental factors. Composite backing boards offer superior results for high-quality, multi-layer PCB applications, while traditional options like phenolic paper and aluminum foil are cost-effective choices for less demanding tasks.