Laser PCB Processing Technology Overview

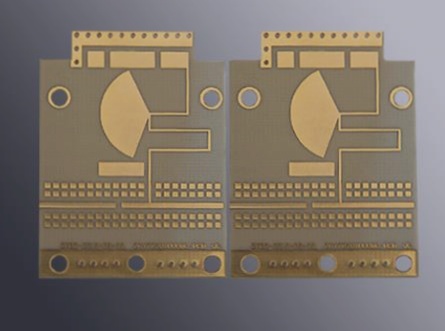

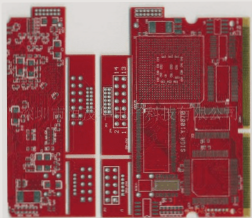

Laser PCB processing technology involves utilizing laser beams to perform various tasks such as cutting, welding, surface treatment, perforation, micromachining, and object identification. This technology is widely used in the PCB fabrication industry.

Applications of Laser Technology in PCB Processing

- Laser Welding: Used for sealing devices like automobile body plates, lithium batteries, cardiac pacemakers, and more, using lasers such as YAG, CO2, and semiconductor pump lasers.

- Laser Cutting: Applied in industries like automotive, computers, and aerospace for cutting materials such as metal parts, acrylic, steel pipes, and titanium alloys using lasers like YAG and CO2.

- Laser Marking: Widely used across various materials and industries with lasers like YAG, CO2, and semiconductor pump lasers.

- Laser Drilling: Primarily used in aerospace, automobile manufacturing, and electronics with lasers like YAG and CO2, for applications like producing synthetic diamond wire drawing dies and multilayer PCBs.

- Laser Heat Treatment: Common in the automotive and aerospace industries for treating parts like cylinder liners and gears using lasers like YAG and CO2.

- Laser Rapid Prototyping: Integrates laser PCB processing with CNC and flexible manufacturing technologies, mainly used in mold and model industries with lasers like YAG and CO2.

- Laser Coating: Extensively used in aerospace, mold, and electromechanical industries with high-power YAG and CO2 lasers.

Research Categories in Laser PCB Processing

Research in laser PCB processing can be classified into laser PCB processing systems, which include lasers, light guide systems, processing machine tools, control systems, and inspection systems.