Micro-assembly Technology in PCBs: The Future of Electronic Assembly

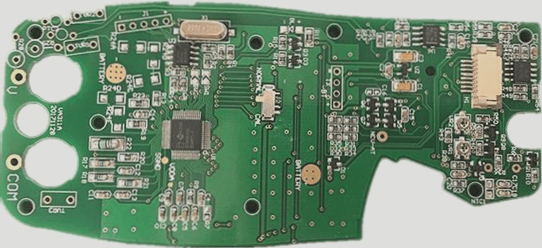

Micro-assembly technology is revolutionizing electronic assembly processes by integrating micro-small electronic components into high-density, high-speed, and high-reliability three-dimensional electronic products on multilayer interconnection circuit boards. These products are significantly smaller than traditional electronics, with improved reliability due to fewer solder joints.

The Role of Surface Mount Components in SMT

- Chip resistors

- Chip trimmer potentiometers

- Chip tantalum electrolytic capacitors

- Chip inductors

- Surface mount tactile switches

- Surface mount connectors

- Integrated circuits

- Hybrid integrated circuits

Advancements in Surface Mount Components

Surface mount components are focusing on miniaturization and high performance, such as high power, high precision, large capacity, high reliability, long life, and high frequency. Integrated circuits now feature ultra-small lead center distances, while chip tantalum electrolytic capacitors boast impressive temperature and humidity characteristics.

The Evolution of Soldering Technology

Soldering plays a critical role in circuit assembly technology, enabling narrow pitch technology. Recent developments include various welding processes like convection infrared reflow welding, vapor phase reflow welding, and lead-free soldering.

The Importance of Placement Equipment

Placement machines are essential in surface mount production systems, achieving high mounting speeds and accuracy. With CCD optical camera correction systems, placement accuracy has reached remarkable levels.

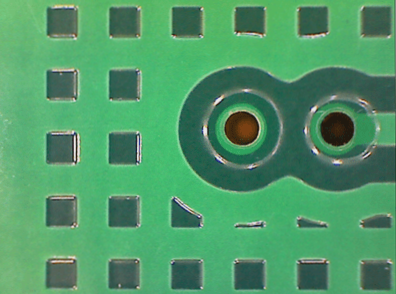

The Significance of Printed Circuit Boards

Printed circuit boards act as carriers for electronic components and aid in heat dissipation. Advancements in PCB technology have led to high-density, high-frequency, and ultra-thin designs, driving changes in design and production technologies.

Key Technologies in PCB Production

- Computer-aided design technology

- Computer integrated manufacturing system technology

- Wiring and plate making

- Metallization technology

- Holeization technology

- Lamination technology

- Material technology

As electronic components continue to evolve towards micro-miniaturization and narrow-pitch requirements, the demand for refined and precise SMT technology is on the rise. Surface mounting processes encompass various technologies, from soldering to PCB design and production, shaping the future of electronic assembly.