PCB Cutting Methods and Techniques

The Importance of Proper PCB Cutting

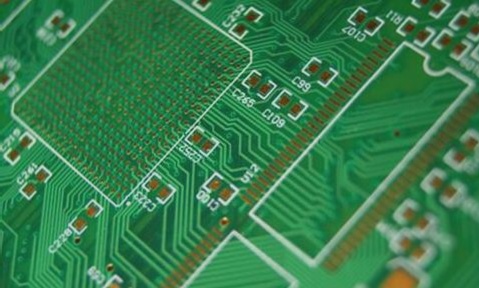

Circuit board cutting is a crucial process in the manufacturing and assembly of PCBs. It involves dividing a PCB into smaller pieces without compromising its functionality. Proper cutting methods are essential to ensure the overall performance of the circuit board.

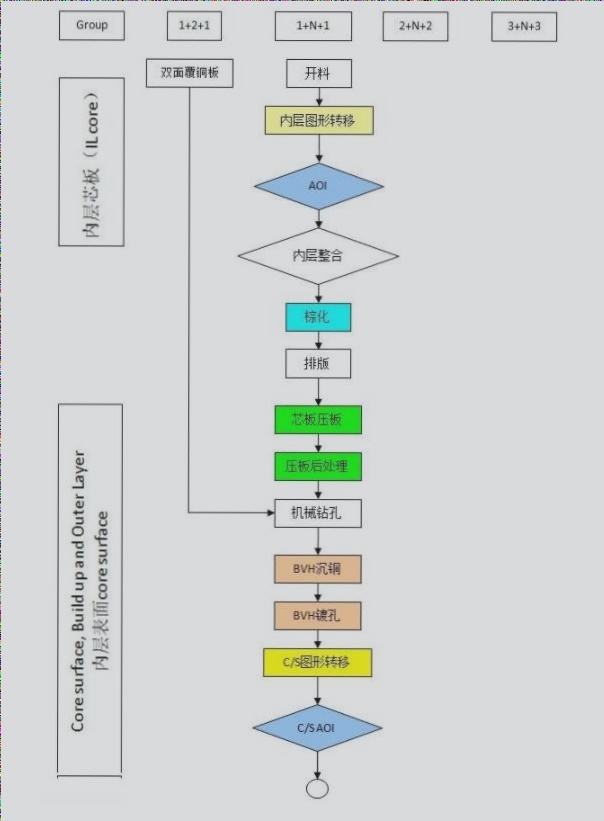

Common PCB Cutting Methods

- Linear Cutting (V-Cutting): This method involves using cutting tools or V-knives to make straight cuts along the edges of the PCB or specified cutting lines.

- Milling and Cutting: CNC milling machines are used for precise shaping and hole positioning according to design documents.

- Wire Cutting: For complex PCBs, wire-cutting technology can achieve high accuracy and complexity in cutting.

- Laser Cutting: Utilizing laser beams for high-precision and complex shape cutting on PCB boards.

V-Cut Cutting Method

V-cutting involves pre-cutting dividing lines on the PCB to facilitate subsequent assembly of SMT circuit boards. It is crucial for maintaining the structural integrity of the PCB.

Key Points about V-Cut:

- V-Cut can only cut straight lines from head to tail and cannot change direction.

- Thin PCBs (< 1.0mm) should avoid V-cut grooves to prevent structural damage.

- Improper V-Cut design can lead to severe deformation during reflow processes.

Stamp Hole Connection

Stamp holes are used for irregular or circular PCBs to provide support and prevent collapse. They are common in creating independent modules for PCB assembly processes.

Conclusion

Proper PCB cutting methods are essential for maintaining the functionality and performance of circuit boards. By utilizing the right cutting techniques, manufacturers can ensure the integrity of PCBs for various applications.

The Benefits of V-Cutting in PCB Manufacturing

V-cutting is a crucial technique in PCB manufacturing that is primarily utilized to separate whole PCB boards into individual pieces. This process plays a significant role in enhancing production efficiency and cutting down costs, especially in large-scale manufacturing operations.