Factors Affecting PCB Prices

- Board Materials: PCBs can be made from materials like FR-4 and CEM-3, impacting costs.

- Board Thickness and Copper Thickness: Ranging from 0.6mm to 3.0mm and ½ Oz to 3 Oz respectively.

- Solder Mask Ink: Differences between ordinary and photosensitive green ink affect material costs.

- Production Processes: Varied processes like gold-plating versus tin-spraying lead to price differences.

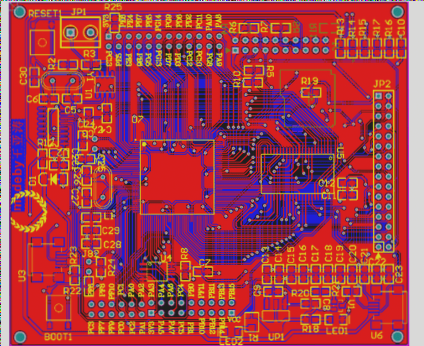

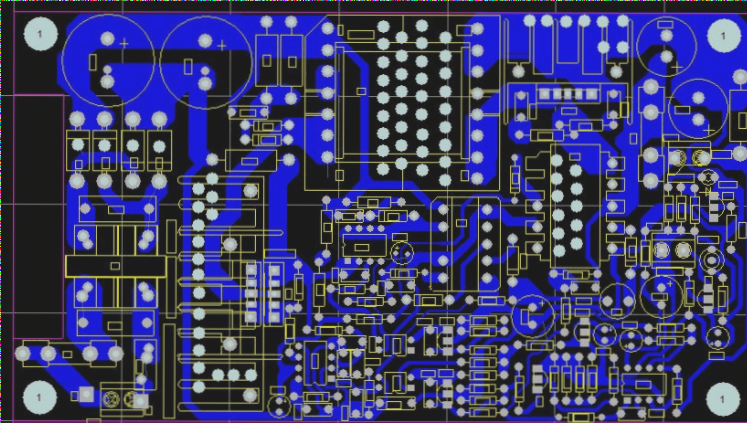

- Complexity of PCB Design: More intricate designs result in higher costs due to drilling and production variations.

- Customer Requirements: Specific demands influence production rates and costs.

- Manufacturer Variances: Different manufacturers have diverse costs based on equipment and expertise.

- Payment Methods: Prices may vary by 5% to 10% depending on the chosen payment method.

- Regional Pricing: Prices in China rise from south to north, impacting overall pricing.

To calculate PCB quotations, consider plate costs, drilling costs, process costs, and labor/utilities/management costs. Raw material prices have recently stabilized, reducing the likelihood of significant price increases.