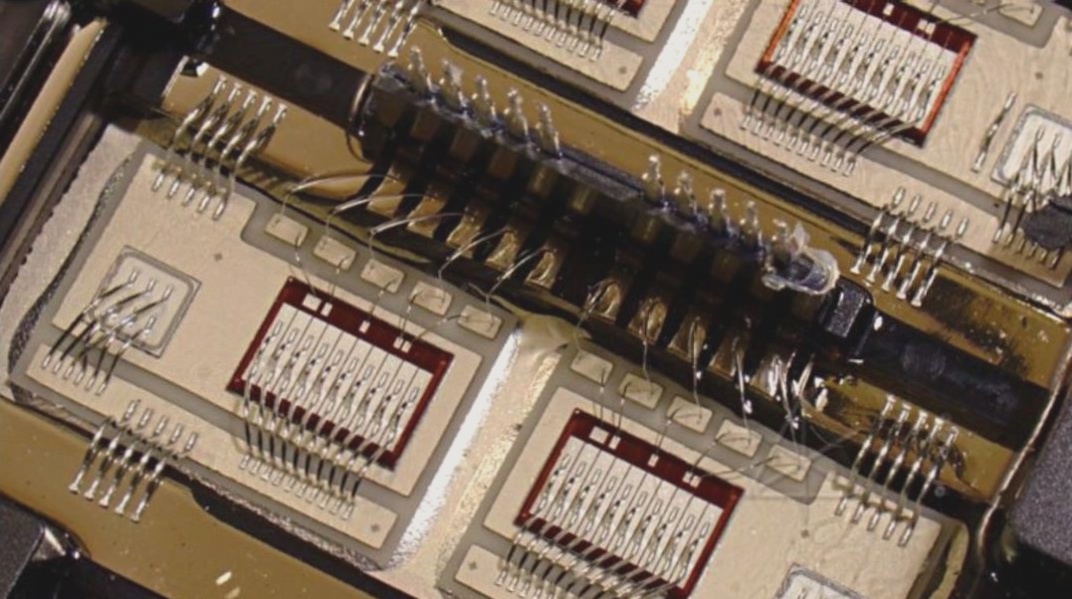

Customizing multi-layer circuit board (PCB) vias is a crucial step in the fabrication process. These vias come in three main types: “blind vias,” “buried vias,” and “through-holes.” Let’s delve into the distinctions among these vias:

① Blind Via: Positioned on the top and bottom surfaces of the circuit board, these vias have a specified depth. They facilitate connections between the surface circuitry and the underlying inner circuitry. Typically, the depth and diameter of blind vias do not exceed certain ratios.

② Buried Via: These vias are located within the inner layers of the PCB and do not extend to the board’s surface. Both blind and buried vias are situated within the inner layers of the circuit board. Prior to lamination, necessary through-holes are drilled. After lamination, these pre-drilled through-holes become inner vias. This scenario is common in multi-layer circuit boards, whereas double-sided boards do not encounter this situation.

③ Through-Hole: These vias penetrate from the bottom layer to the top layer, serving purposes such as internal interconnection or serving as positioning holes for components. Due to their ease of implementation and cost-effectiveness, through-holes are commonly used in printed circuit boards.

Employing blind and buried vias can reduce the size and layer count of the circuit board to some extent. Additionally, they can enhance electromagnetic compatibility, lower customization costs, and augment product features. Conversely, through-holes consume significant wiring space. Dense concentrations of through-holes can impede inner wiring in multi-layer circuit boards. When densely packed through-holes traverse the surface between the power and ground layers, they not only disrupt the impedance characteristics of the power-ground layer but also risk causing layer failures in the power-ground wiring. However, the specific design of vias depends on the product requirements of the customer. Not all multi-layer circuit boards necessitate the use of blind or buried vias.

① Blind Via: Positioned on the top and bottom surfaces of the circuit board, these vias have a specified depth. They facilitate connections between the surface circuitry and the underlying inner circuitry. Typically, the depth and diameter of blind vias do not exceed certain ratios.

② Buried Via: These vias are located within the inner layers of the PCB and do not extend to the board’s surface. Both blind and buried vias are situated within the inner layers of the circuit board. Prior to lamination, necessary through-holes are drilled. After lamination, these pre-drilled through-holes become inner vias. This scenario is common in multi-layer circuit boards, whereas double-sided boards do not encounter this situation.

③ Through-Hole: These vias penetrate from the bottom layer to the top layer, serving purposes such as internal interconnection or serving as positioning holes for components. Due to their ease of implementation and cost-effectiveness, through-holes are commonly used in printed circuit boards.

Employing blind and buried vias can reduce the size and layer count of the circuit board to some extent. Additionally, they can enhance electromagnetic compatibility, lower customization costs, and augment product features. Conversely, through-holes consume significant wiring space. Dense concentrations of through-holes can impede inner wiring in multi-layer circuit boards. When densely packed through-holes traverse the surface between the power and ground layers, they not only disrupt the impedance characteristics of the power-ground layer but also risk causing layer failures in the power-ground wiring. However, the specific design of vias depends on the product requirements of the customer. Not all multi-layer circuit boards necessitate the use of blind or buried vias.