PCB Board Production Methods

Method 1: Wax Paper Printing

- Cut copper clad board to circuit size.

- Create circuit design on wax paper.

- Print circuit onto board using printing material.

- Etch using potassium chlorate solution.

- Rinse, clean, and drill holes.

Method 2: Standard Pad Design

- Create accurate pad and connection designs.

- Cut and clean printing plate.

- Transfer diagram and apply pads.

- Secure components and etch with ferric chloride.

- Polish, apply rosin solution, and dry.

Latest Updates:

Recent advancements in PCB production methods have focused on the use of eco-friendly materials and automated processes to increase efficiency and reduce waste. Companies are investing in AI technology to optimize circuit designs and minimize errors during production. Additionally, the integration of IoT devices in PCB manufacturing has enabled real-time monitoring of production processes, leading to improved quality control and faster turnaround times.

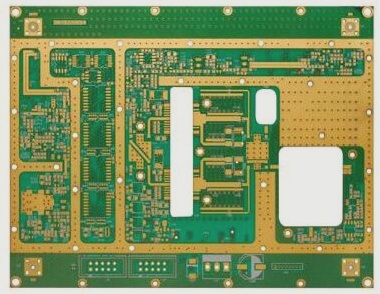

Sub-Printing Method for PCB Fabrication

- Print or hand-draw the circuit diagram on 80gsm copy paper at a 1:1 scale, ensuring the paper is flat.

- Replace fax machine paper with hot melt plastic film and copy the circuit diagram onto the plastic film using the fax machine’s copy function.

- Secure the plastic film flatly onto the copper-clad plate using double-sided tape, ensuring no wrinkles and avoiding tape over the melted part for production quality.

- Apply paint evenly on the plastic film with a paintbrush, using single-direction strokes to prevent film wrinkling and overlapping on the copper plate lines. Remove the plastic film carefully after completing the circuit diagram and dry thoroughly before etching. For mass production, align multiple boards under a silk screen using a wooden frame and apply paint in one direction with consistent pressure. Correct errors with paint and bamboo tools, adjusting brush pressure for optimal results.

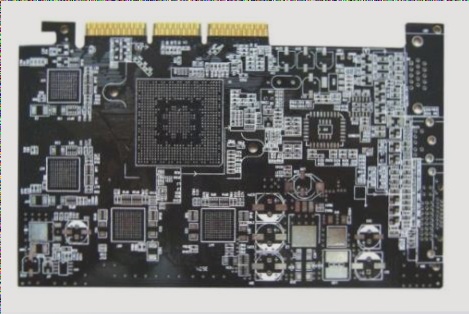

Introduction to PCB Board Process in PROTEL

Newcomers often find Protel software user-friendly but may struggle with non-software concepts crucial to PCB design. Understanding the modern PCB manufacturing flow—from single-sided to multi-layer boards—is essential for effective design.

Key steps include cutting, screen printing, etching, material removal, drilling, marking, flux application, and finalizing products. Protel layers directly influence the physical PCB, accommodating dense electronic components and wiring needs. Multi-layer boards support complex circuits with specialized power and signal layers interconnected by vias.

Silkscreen layers display essential component details, optimizing assembly and maintenance. Integrating SMD components requires surface-specific design and careful attention to pad placement. External plane and fill areas aid circuit performance, particularly in shielding and high-current environments.

Customizing pad types ensures structural integrity and thermal management. Solder masks protect against unwanted tin adhesion, crucial for reliable soldering. Optimizing via usage minimizes signal interference and supports high-current paths.

Understanding these principles is fundamental for mastering Protel and achieving efficient PCB designs.