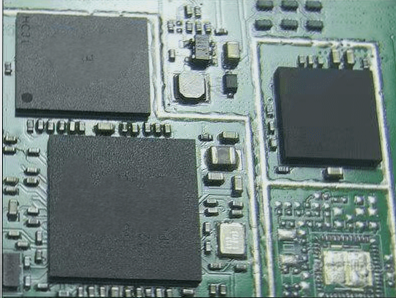

WellCircuits Limited recently encountered the issue of component tilting during SMT chip processing for customers, as shown in the image provided. In such cases, the component appears soldered but is not securely attached to the board. Typically, our workers are required to address this issue manually.

This situation is a common occurrence during SMT patch proofing at WellCircuits Limited. While many customers supply the materials for processing, they may not always enforce strict component control, leading to potential issues with individual components. When components are found to be tilted, we conduct a thorough examination, checking the following points:

1. Ensure that the PCB is not deformed.

2. Verify that parameters such as IC thickness and mounting pressure are within normal limits.

3. Confirm that the support pin setting on the SMT placement machine is appropriate.

4. Check that the suction position is centered on the component.

5. Inspect the Tray Feeder housing the IC to ensure it is functioning properly.

6. Review the parameter settings of the reflow oven to meet requirements.

7. Assess whether the storage environment for components meets temperature and humidity guidelines.

If the issue stems from a faulty component, we will transparently report it to the customer and assist in sourcing components from reliable suppliers. WellCircuits Limited remains committed to delivering top-notch service to our valued customers.

This situation is a common occurrence during SMT patch proofing at WellCircuits Limited. While many customers supply the materials for processing, they may not always enforce strict component control, leading to potential issues with individual components. When components are found to be tilted, we conduct a thorough examination, checking the following points:

1. Ensure that the PCB is not deformed.

2. Verify that parameters such as IC thickness and mounting pressure are within normal limits.

3. Confirm that the support pin setting on the SMT placement machine is appropriate.

4. Check that the suction position is centered on the component.

5. Inspect the Tray Feeder housing the IC to ensure it is functioning properly.

6. Review the parameter settings of the reflow oven to meet requirements.

7. Assess whether the storage environment for components meets temperature and humidity guidelines.

If the issue stems from a faulty component, we will transparently report it to the customer and assist in sourcing components from reliable suppliers. WellCircuits Limited remains committed to delivering top-notch service to our valued customers.