The Basics of Single-Sided PCB Boards

Introduction to Single-Sided PCB

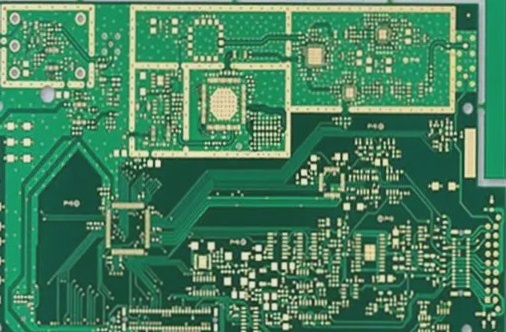

Single-sided PCB boards are commonly used in electronic manufacturing for simple circuit designs. These boards consist of a single circuit and electronic components, making them ideal for products like calculators and toys.

Key Features of Single-Sided PCB

- Reduces errors in wiring and assembly, saving time for maintenance and inspection

- Standardized design for easy interchangeability

- High wiring density, small size, and lightweight for electronic equipment miniaturization

- Facilitates mechanized and automated production, reducing equipment costs

Applications of Single-Sided PCB

Single-sided PCBs are used in various industries such as LCD, FPC, chemical, and electrical isolation. They are commonly found in household appliances, commercial machines, and electronic components.

Manufacturing Process of Single-Sided PCB

The manufacturing process involves material cutting, drilling, copper sinking, circuit production, electroplating, etching, surface treatment, testing, and packaging. Tools like printers, UV exposure machines, and etchants are used in the production process.

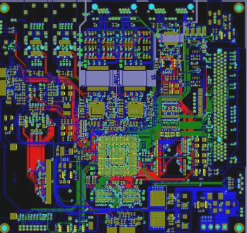

Designing a Single-Sided PCB

To create a single-sided PCB, design the circuit diagram and print it on transparent photosensitive film. Ensure the circuit diagram is mirrored for correct etching on the copper plate.

Production Process of Single-Sided PCB Boards

To create a single-sided PCB board, start by cleaning the copper plate and roughening its surface with sandpaper. This helps the photosensitive film adhere better to the copper plate. Then, place the photosensitive film on the copper plate and expose it using a UV exposure machine. This exposure initiates a chemical reaction between the patterns on the film and the copper plate surface.

After exposure, immerse the copper plate in an etching solution. The solution etches and removes the non-circuit parts on the plate’s surface. Once done, thoroughly clean the copper plate. At this stage, the copper plate should exhibit the circuit pattern, indicating the formation of the required circuit pattern.

Next, use a drilling machine to drill holes in specific positions on the copper plate. These holes facilitate connections when soldering components onto the circuit board, marking the completion of the single-sided PCB board production.

Significance of Single-Sided PCB Boards

Single-sided PCB boards are essential components in almost all electronic devices. They enable the electrical interconnection between various electronic components, such as integrated circuits, in devices ranging from electronic watches and calculators to advanced computers, communication devices, and military systems.

PCBs provide mechanical support for assembling electronic components, establish wiring and electrical connections, ensure electrical insulation between components, and define essential electrical characteristics like characteristic impedance. Additionally, PCBs offer solder mask graphics for automated soldering, as well as identification characters and graphics for component insertion, inspection, and maintenance.