The turnkey PCB manufacturing and assembling process is quite simple as if we talk about general PCB assembling and manufacturing. Printed circuit boards are necessary for all electronics and digital machines or appliances. Earlier PCB manufacturing was a hectic task and wasted time and money.

The turnkey manufacturers used to start manufacturing directly, which may result in the wastage of money and time if any step or part goes wrong in the turnkey PCB. Just like humans, electronic devices also need a brain to control all activities and provide energy to the rest of the body in the sense of coordination.

PCB assembly manufacturers provide multiple services to their customers online and deliver the printed circuit board assemblies to their clients.

What are the 6 stages of manufacturing and assembling Turnkey PCB?

Unlike the older ages, the manufacturers work in the dark without assuming the consequences of using different dimensions. Technology has made their work easier, and they plan just like other projects to manage each step and keep track of it. This type of management helps to get the best result in a single turn and saves time and cost.

Is a turnkey PCB assembly the same as PCB assembly?

Turnkey PCB assembly is quite different from consigning PCB assembly as PCB manufacturers design, manufacture, and assemble turnkey PCB all under a single roof, while consigning PCB assembly goes to different hands for each process.

It depends on the client what he wants to do either they want to prepare the PCB assembly from a single person or buy different parts from different manufacturers and get it assembled by his engineers.

6 major stages of manufacturing and assembly of turnkey PCB

So, whatever the reasons, turnkey PCB manufacturing is rocking high due to its safe and less expensive nature. The turnkey manufacturing and assembly process is now quite organized and planned to avoid inconvenience. The manufacturers observe six major steps to safely reach the proper Turnkey PCB manufacturing, assembling, and delivery to their client. Following are the six main steps of manufacturing and assembling turnkey PCB.

High-quality but money-saving prototyping

Earlier, the manufacturers did not look for the plan to have enough tools to decide whether they would get the same results of turnkey PCB assembly or not. They directly go for the manufacturing process by developing circuits using different electronic parts.

Humans can make mistakes even if they have experience doing specific work. So, the circuit the manufacturers develop may get the wrong way which will ruin all the money the manufacturer has invested in buying different components for developing the circuit.

But now, in this modern age of technology, the manufacturers have developed software to work on designing or 3D modeling in which you can see what you are going to design and how it would be suitable for the specific device for which clients have asked building the turnkey PCB assembly.

Manufacturers put their PCB assembly designs online to offer device manufacturers their services. Turnkey manufacturers now offer their design with more proficiency with an offer of asking for the design of their client’s choice.

They approach the people uploading their design on the portal, get viral, and win the project of manufacturing turnkey PCB.

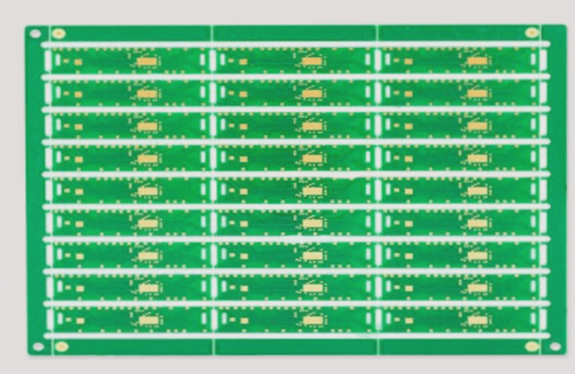

Manufacturing of Turnkey PCB

When the turnkey PCB design is ready, it is confirmed that it will suit the turnkey PCB assembly. By using sophisticated software, manufacturers go through prototyping and get the approval of the design from the clients, usually online clients. Now, it is time to manufacture turnkey PCBs, which usually becomes easy after prototyping.

Now, the manufacturer is ready to deal with the manufacturing of turnkey PCBs from simple and small designs to complex designs. The use of software makes the manufacturing process easy for PCB manufacturers.

- As per the turnkey PCB design’s complexity and simplicity, the manufacturers can charge the customer

- Usually, the manufacturers are not responsible for the material and components used in the PCB manufacturing as the client suggests or provide the material or components for circuit development.

- During manufacturing, the manufacturers follow different steps for developing circuits like preparing board, adding copper, printing inner layers, alignment of layers and their bonding, etc.

Depending on the complexity of manufacturing, turnkey PCB manufacturers can demand the cost of the project. Situations can change but the type of design plays an important role.

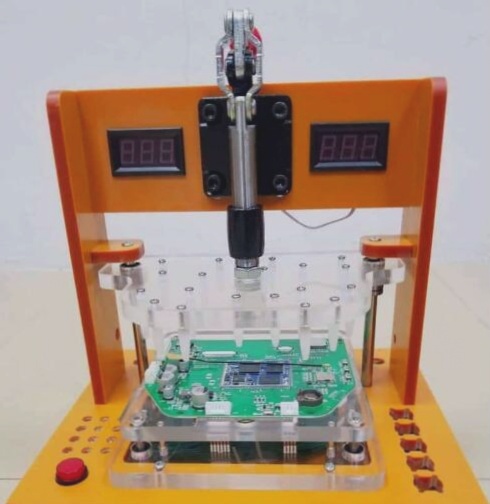

Assembling of different electronic components devices

Turnkey PCB manufacturing leads to the assembling of these PCBs to create an assembly to make it the brain of different electron and digital devices. Some clients only order turnkey PCBs from one manufacturer and order the PCB assembly from another manufacturer, but many of them prefer to get the PCB assembly from the same manufacturer.

- If they hire the same company or the manufacturer for turnkey PCB manufacturing, they will create the best assembly of turnkey PCB and other electronic devices.

- The electronic companies having a contract with manufacturers usually hire them to assemble the electronic components of the devices.

- After having the contract, the electronic companies deliver the relevant components of the electronic device, share their plan and needs for the devices, and the manufacturers start work accordingly.

In the case of Turnkey PCB manufacturing and assembly, the working rule is to choose the same manufacturer for PCB manufacturing and assembling of other electronic components of the devices. It will be helpful to provide the electronic companies smooth and painless experience. It will not only make the electronic devices’ power system outclass but also ensure the best packaging and on-time delivery. By choosing the turnkey manufacturing and assembly of PCB, you are choosing tension-free services and ample time to focus on your business and leave the rest of working on your partner manufacturing company.

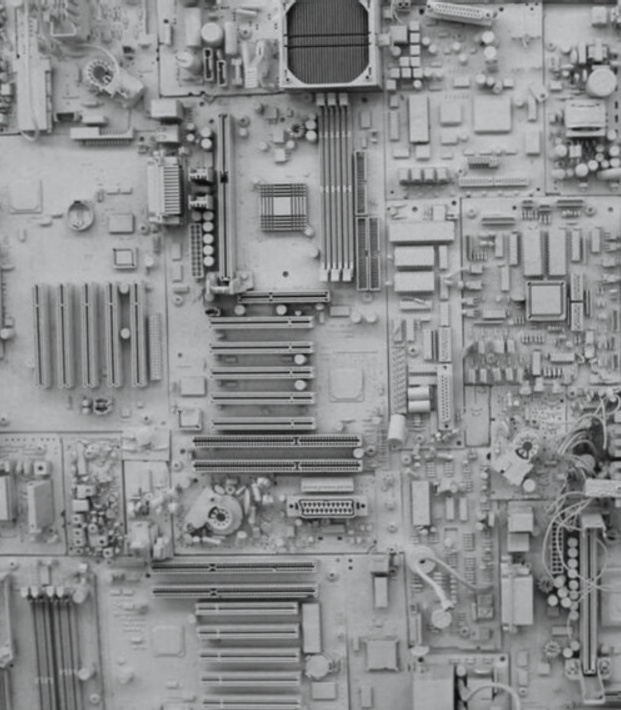

Testing of turnkey PCB assembly

When the circuit board is after the turnkey PCB assembly, it is time to check whether everything in the circuit is in the right place or not. For this purpose, the manufacturing company holds two types of tests, the initial test and the final test.

- For this purpose, the manufacturer company not only checks the PCB solder paste, mounting, and soldering but also keenly looks into the PCB assembly with other electric devices to create a proper circuit board like the motherboard in a computer.

- This circuit board is responsible for the working of the whole device as everything is under its control as it is acting as the brain of the device.

For the final test and finishing, the manufacturing company asks for the outer packaging you want to have for your product. The electronic company will share the picture of the final packaging of the product, and the manufacturing company will create the same like to deliver the best for your product. It is a very important step as testing thoroughly is key.

Safe storage and management of Turnkey PCB

As electronic companies do not order the PCB manufacturing and assembly in a small amount usually, they have hundreds or thousands of products for which they need PCB assembly so, so the manufacturing company needs to have proper storage and management of the PCB assembly. Here, the manufacturer company needs to be proactive in managing things brilliantly and delivering a quality product to their clients.

The electronic device-making company should hand over this responsibility to the manufacturers as it has done all previous steps wonderfully.

The device PCB assembly manufacturers have ample space and management skills that are far better than that you hire a place to keep your order until it gets shipped. The professional and skilled team will properly manage the PCB assembly along with packaging while having a record of each of them.

Integration system

When you are choosing a company for manufacturing PCB assembly by using API, you are defining very clearly that the company is responsible for preparing and delivering the order.

- The electronic device company will just order the PCB design by looking at the portfolio and staying relaxed for the order placement and shipping.

- In the case of manufacturing and assembly of turnkey PCBs, you just need to place an order, stay calm, and focus on your business.

- You will get the organized, packed, and on-time delivery of your order.

You do not need to get the headache of contacting another company for shipment as the manufacturer company does it by itself. So, you are free to focus on the growth of your company, making strategies for effective marketing, and carving a new way to success.

Conclusion

As explained in this article, turnkey PCB assembly is different from the consign PCB assembly as the order maker does not need to worry about anything after placing an order. After order placement and providing general information about your product and expectations, you are free to focus on your business. The manufacturer company will plan, manufacture, assemble, pack, and deliver the PCB turnkey PCB assembly at your door on time.