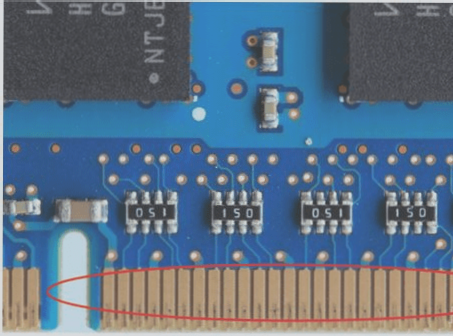

In PCB design, discussions about serpentine lines frequently arise. These lines are commonly found in high-speed, high-density boards, which are often regarded as advanced designs, showcasing expertise in their creation. Numerous articles online address serpentine lines, but some may mislead novices, causing confusion and unnecessary challenges. Let’s explore the practical applications of serpentine lines.

To grasp the concept of serpentine lines, we first need to discuss PCB routing. This topic likely doesn’t require much introduction, as wiring is a daily task for hardware engineers. Each trace on a PCB is meticulously drawn by engineers. While this may seem straightforward, routing involves numerous principles that are often overlooked, such as the concepts of microstrip and stripline. In essence, a microstrip line is a trace located on the surface of the PCB, whereas a stripline is situated within the inner layers. What distinguishes these two types? The reference plane for a microstrip line is the ground plane of the inner layer, with the opposite side of the trace exposed to air, resulting in differing dielectric constants. For example, the dielectric constant of the commonly used FR4 substrate is around 4.2, while that of air is 1. In contrast, a stripline is surrounded by reference planes on both its top and bottom sides.

1. The entire trace is situated close to the PCB substrate, and the dielectric constant surrounding the trace remains uniform. This configuration facilitates the transmission of TEM waves along the strip line and quasi-TEM waves along the microstrip line. Why are they termed quasi-TEM waves? This phenomenon arises from the phase mismatch at the boundary between air and the PCB substrate. What is a TEM wave? … Delving deeper into this topic could take us far beyond ten and a half months. To summarize, whether dealing with a microstrip line or a stripline, their primary function is to convey signals, be they digital or analog. These signals travel as electromagnetic waves from one end of the trace to the other. Since they are waves, they possess speed. What is the speed of the signal on a PCB trace? This varies depending on the dielectric constant, leading to different speeds. The speed of electromagnetic waves in air is commonly recognized as the speed of light. The propagation velocity in other media can be calculated using the following formula:

2. ( V = frac{C}{sqrt{E_r}} )

In this equation, ( V ) represents the propagation speed in the medium, ( C ) is the speed of light, and ( E_r ) is the dielectric constant of the medium. Using this formula, we can readily determine the transmission speed of the signal on a PCB trace. For instance, if we input the dielectric constant of the FR4 substrate into the formula, we find that the transmission speed of signals in FR4 is approximately half the speed of light. However, for the microstrip line located on the surface layer, since half of it is in air and the other half in the substrate, the dielectric constant is slightly reduced, resulting in a marginally faster transmission speed compared to the stripline. Empirical data indicates that the trace delay for microstrip lines is around 140 ps/inch, whereas for striplines, it is approximately 166 ps/inch.

3. As previously mentioned, the primary concern is the delay in signal transmission on the PCB. In other words, the signal does not travel instantaneously from one pin to another through the trace. Although the signal transmission speed is extremely high, a sufficiently long trace can still impact signal delivery. For example, a 1 GHz signal has a period of 1 ns, with the rise or fall time being about one-tenth of that period, or 100 ps. If our trace exceeds 1 inch (about 2.54 cm), the transmission delay will be greater than the rise time. If the trace exceeds 8 inches (approximately 20 cm), the delay could encompass a full cycle! Thus, the influence of the PCB can be significant, and it’s common for our boards to feature traces longer than 1 inch. So, does this delay affect the board’s normal operation? In practical systems, if only one signal is present and others remain inactive, the delay may appear negligible. However, in high-speed systems, this delay can indeed have an impact.

4. Similar to other traces, common routing rules apply to serpentine lines. However, due to the unique structure of serpentine lines, special care should be taken during layout. For instance, aim to keep serpentine lines parallel and spaced apart. Shorter lengths are preferable; as the saying goes, avoid making tight bends in confined areas. Such practices help minimize signal interference. The added length of serpentine lines can adversely affect the signal, so if the timing requirements of the system can be met without them, it is best to avoid using them. Some engineers use serpentine lines to equalize lengths for DDR or high-speed signals across the board. While this may seem like a better layout approach, in practice, it often reflects poor management of trace lengths and unnecessary complexity. Unneeded winding not only wastes board area but can also degrade signal quality. It is advisable to calculate necessary delay redundancy based on actual signal speed requirements before establishing board routing rules.

5. Beyond equal length considerations, I have encountered several other frequently discussed effects of serpentine lines in online articles, which I will briefly outline here.

1. A commonly referenced argument pertains to impedance matching. This notion is puzzling. The impedance of PCB traces depends on line width, dielectric constant, and the distance to the reference plane, not on the serpentine shape itself. I am unclear on the origin of this assertion.

2. Filtering effects are also mentioned. While these effects may exist, they are not relevant for digital circuits. In RF circuits, serpentine traces can form LC circuits, potentially filtering signals at certain frequencies, but this is not typically applicable to digital designs.

3. Inductance is a relevant consideration. All traces on a PCB exhibit parasitic inductance, and some PCB inductors can indeed be created.

4. Antenna effects can also be observed; this is evident in devices like mobile phones or radios, where certain antennas are designed using PCB traces.

5. The idea of using serpentine lines as fuses is puzzling. How can a short, narrow serpentine trace function as a fuse? Would it burn out under high current? This approach seems impractical, and the cost of such a “fuse” would be prohibitive. I find it difficult to understand what applications would warrant this.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me

To grasp the concept of serpentine lines, we first need to discuss PCB routing. This topic likely doesn’t require much introduction, as wiring is a daily task for hardware engineers. Each trace on a PCB is meticulously drawn by engineers. While this may seem straightforward, routing involves numerous principles that are often overlooked, such as the concepts of microstrip and stripline. In essence, a microstrip line is a trace located on the surface of the PCB, whereas a stripline is situated within the inner layers. What distinguishes these two types? The reference plane for a microstrip line is the ground plane of the inner layer, with the opposite side of the trace exposed to air, resulting in differing dielectric constants. For example, the dielectric constant of the commonly used FR4 substrate is around 4.2, while that of air is 1. In contrast, a stripline is surrounded by reference planes on both its top and bottom sides.

1. The entire trace is situated close to the PCB substrate, and the dielectric constant surrounding the trace remains uniform. This configuration facilitates the transmission of TEM waves along the strip line and quasi-TEM waves along the microstrip line. Why are they termed quasi-TEM waves? This phenomenon arises from the phase mismatch at the boundary between air and the PCB substrate. What is a TEM wave? … Delving deeper into this topic could take us far beyond ten and a half months. To summarize, whether dealing with a microstrip line or a stripline, their primary function is to convey signals, be they digital or analog. These signals travel as electromagnetic waves from one end of the trace to the other. Since they are waves, they possess speed. What is the speed of the signal on a PCB trace? This varies depending on the dielectric constant, leading to different speeds. The speed of electromagnetic waves in air is commonly recognized as the speed of light. The propagation velocity in other media can be calculated using the following formula:

2. ( V = frac{C}{sqrt{E_r}} )

In this equation, ( V ) represents the propagation speed in the medium, ( C ) is the speed of light, and ( E_r ) is the dielectric constant of the medium. Using this formula, we can readily determine the transmission speed of the signal on a PCB trace. For instance, if we input the dielectric constant of the FR4 substrate into the formula, we find that the transmission speed of signals in FR4 is approximately half the speed of light. However, for the microstrip line located on the surface layer, since half of it is in air and the other half in the substrate, the dielectric constant is slightly reduced, resulting in a marginally faster transmission speed compared to the stripline. Empirical data indicates that the trace delay for microstrip lines is around 140 ps/inch, whereas for striplines, it is approximately 166 ps/inch.

3. As previously mentioned, the primary concern is the delay in signal transmission on the PCB. In other words, the signal does not travel instantaneously from one pin to another through the trace. Although the signal transmission speed is extremely high, a sufficiently long trace can still impact signal delivery. For example, a 1 GHz signal has a period of 1 ns, with the rise or fall time being about one-tenth of that period, or 100 ps. If our trace exceeds 1 inch (about 2.54 cm), the transmission delay will be greater than the rise time. If the trace exceeds 8 inches (approximately 20 cm), the delay could encompass a full cycle! Thus, the influence of the PCB can be significant, and it’s common for our boards to feature traces longer than 1 inch. So, does this delay affect the board’s normal operation? In practical systems, if only one signal is present and others remain inactive, the delay may appear negligible. However, in high-speed systems, this delay can indeed have an impact.

4. Similar to other traces, common routing rules apply to serpentine lines. However, due to the unique structure of serpentine lines, special care should be taken during layout. For instance, aim to keep serpentine lines parallel and spaced apart. Shorter lengths are preferable; as the saying goes, avoid making tight bends in confined areas. Such practices help minimize signal interference. The added length of serpentine lines can adversely affect the signal, so if the timing requirements of the system can be met without them, it is best to avoid using them. Some engineers use serpentine lines to equalize lengths for DDR or high-speed signals across the board. While this may seem like a better layout approach, in practice, it often reflects poor management of trace lengths and unnecessary complexity. Unneeded winding not only wastes board area but can also degrade signal quality. It is advisable to calculate necessary delay redundancy based on actual signal speed requirements before establishing board routing rules.

5. Beyond equal length considerations, I have encountered several other frequently discussed effects of serpentine lines in online articles, which I will briefly outline here.

1. A commonly referenced argument pertains to impedance matching. This notion is puzzling. The impedance of PCB traces depends on line width, dielectric constant, and the distance to the reference plane, not on the serpentine shape itself. I am unclear on the origin of this assertion.

2. Filtering effects are also mentioned. While these effects may exist, they are not relevant for digital circuits. In RF circuits, serpentine traces can form LC circuits, potentially filtering signals at certain frequencies, but this is not typically applicable to digital designs.

3. Inductance is a relevant consideration. All traces on a PCB exhibit parasitic inductance, and some PCB inductors can indeed be created.

4. Antenna effects can also be observed; this is evident in devices like mobile phones or radios, where certain antennas are designed using PCB traces.

5. The idea of using serpentine lines as fuses is puzzling. How can a short, narrow serpentine trace function as a fuse? Would it burn out under high current? This approach seems impractical, and the cost of such a “fuse” would be prohibitive. I find it difficult to understand what applications would warrant this.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me