PCB Design: Streamlining the Development Process

Transforming Concepts into Functional Products Efficiently

Creating a printed circuit board (PCB) that meets design specifications is crucial but challenging. Design engineers aim to convert initial concepts into functional products quickly and reliably to accelerate time-to-market.

Utilizing Advanced Software Tools for Efficient Design

Designers now leverage advanced software tools to streamline the PCB design process. These tools facilitate rapid iteration and refinement, converting ideas into detailed designs with confidence. By minimizing errors and optimizing project time, designers can manufacture PCBs that meet functional requirements efficiently.

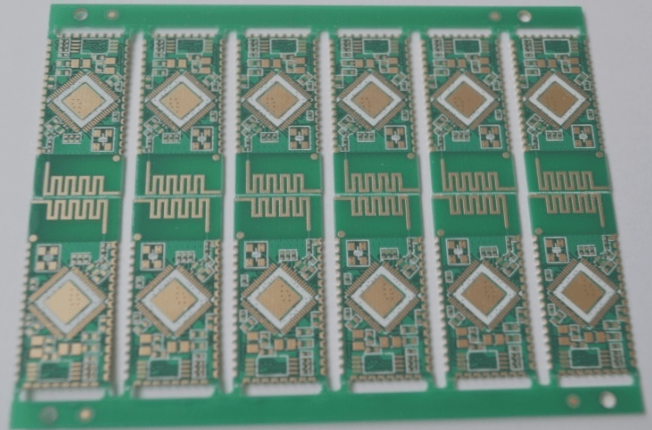

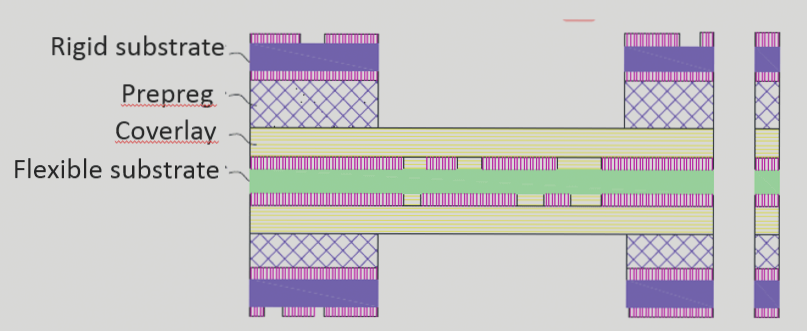

Advancements in Electronic Technologies

Electronic technologies are integrated into various products, driving the need for sophisticated circuits, smaller form factors, and higher performance. This evolution leads to the development of high-density interconnect (HDI) and flexible PCBs, pushing the boundaries of modern electronics.

Design for Manufacturing (DFM) in PCB Development

Design for Manufacturing (DFM) plays a critical role in PCB development, ensuring designs are not only functional but also manufacturable. DFM capabilities in design software help identify manufacturing issues early, enhancing collaboration between designers and manufacturers to expedite the manufacturing process and reduce costs.

Advantages of PCB Design Software

- Quick Start: Reuse previous designs for rapid project initiation.

- Component Library: Access extensive libraries for customizable components.

- Intuitive Routing Tools: Easy placement and movement of routing elements.

- Quality Improvement: Enhance design quality with Design Rule Check (DRC).

- File Generation: Easily generate production files for manufacturing.

- Time Savings: Identify and resolve design issues early to reduce delays.

- Design for Manufacturability (DFM): Optimize designs for manufacturing processes.

- Engineering Change Tracking

Advantages of PCB Design Software

- Modifications made during the design process are automatically tracked and recorded, ensuring transparency and reducing errors during revisions.

- Collaboration is promoted through design software, allowing engineers to share designs, receive feedback, and improve the final product.

- Automatic placement and drag-and-drop features simplify the design process, enhancing efficiency and accuracy in creating complex PCBs.

- Document generation is automated, saving time by eliminating the need for manual creation of PCB layouts, schematics, and component lists.

- Integrity checks alert designers to potential defects early on, preventing costly mistakes and ensuring the final design meets specifications.

Challenges of Not Using PCB Design Software

- Missed deadlines and delayed time-to-market compared to competitors using PCB design software.

- Quality and reliability issues due to manual design methods being more error-prone.

- Increased costs from inefficient workflows and higher production costs without automated design tools.

- Slower design updates and revisions when using manual processes instead of advanced design software.

In conclusion, utilizing PCB design software accelerates the design process, improves product quality, and enhances collaboration, essential elements in today’s competitive market. For any inquiries regarding PCB or PCBA, contact me at info@wellcircuits.com.