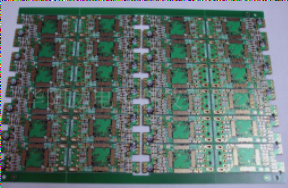

Advantages of Small Batch PCB Assembly

- Cost Efficiency: Small batch PCB assembly minimizes waste and reduces unnecessary overhead costs by producing only as many boards as needed. This approach is particularly beneficial for companies developing cutting-edge products.

- Faster Turnaround Times: Small batch PCB assembly enables rapid prototyping and testing cycles, crucial for industries where time-to-market is a critical factor.

- Flexibility in Design Changes: Small batch production allows for more frequent adjustments to the PCB layout, component selection, and design elements, ensuring the final product aligns closely with the latest requirements.

- Reduced Inventory Risk: Small batch assembly minimizes excess inventory costs and storage issues associated with large inventories, especially valuable for companies working with evolving technologies.

In the prototype phase, products often undergo design and functionality improvisation. Low-volume production offers benefits in terms of cost, efficiency, and risk management. Small-volume production minimizes storage costs and prevents excess inventory accumulation, providing an effective method for testing product designs and functionality.

The fast turnaround time of low-volume PCB production allows rapid evaluation of design changes, ensuring companies can respond effectively to market demands and stay ahead of the competition.

Advantages of Small Batch PCB Assembly

Business success often depends on the ability to adapt quickly to change. Small-volume PCB assembly provides a crucial advantage in this aspect. By steering clear of large-scale production, companies can enjoy faster turnaround times, allowing for prompt defect identification and design flaw rectification. This flexibility enables businesses to incorporate feedback swiftly and tailor products to better suit customer needs, ultimately enhancing the chances of success.

Enhancing Product Quality

The rapid production of PCB prototypes and early detection of defects significantly contribute to the quality of the final product. Detecting issues at an early stage empowers companies to refine and enhance their designs, ensuring a high-quality product launch. This not only enhances credibility but also assists manufacturers in building a strong reputation in the market, as the product undergoes testing and validation before mass production.

Accessible to Startups and Enthusiasts

Small batch PCB assembly has democratized innovation, providing a level playing field for not just large corporations but also startups and hobbyists to explore ideas without substantial financial risks. The affordability of testing concepts in small batches simplifies the process for small businesses to experiment with new ideas. For startups seeking funding, presenting a proof of concept, rather than just a business plan, is invaluable in showcasing product potential and instilling confidence in potential investors.

Final Thoughts

Small batch PCB assembly offers a plethora of benefits, including cost savings through outsourcing, faster turnaround times, and a low-risk approach to testing novel concepts. It empowers businesses to stay nimble, react promptly to design alterations, and ensure the production of top-notch products. Moreover, it creates avenues for startups and enthusiasts to materialize their visions without requiring substantial initial investments, positioning it as a crucial strategy for fostering innovation and achieving success in the market.