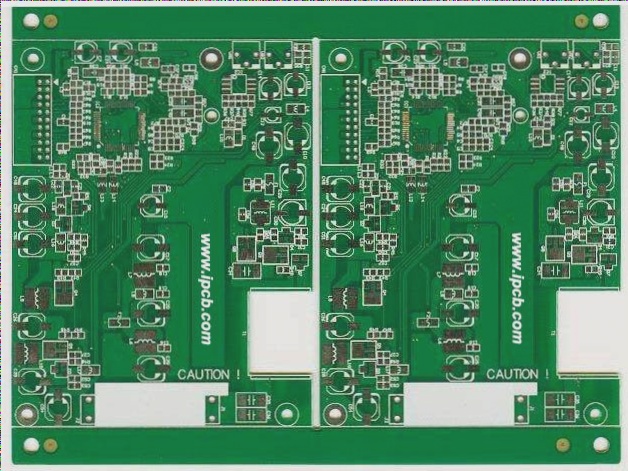

Key Features of High-Reliability Multi-Sided PCB Boards

- Enhanced Reliability: Multi-sided PCB boards offer improved z-axis expansion resistance, contributing to their durability.

- Risks to Consider: Electrical connectivity issues, such as inner layer separation and hole wall cracking, may occur during assembly. Potential failures under load conditions are also a concern.

- IPC Class2 Standard: For most factories, adherence to the IPC Class2 standard, which mandates less than 20% copper plating on PCB multilayers, is crucial.

- Perfect Circuitry: High-reliability multi-sided boards ensure safety and reliability without the need for maintenance. However, improper maintenance can lead to open circuits or malfunctions under load conditions.

- Improved Cleanliness: Maintaining cleanliness on PCB multilayer boards is essential for enhancing reliability. Residues, solder accumulation, and ion residues can all pose risks to the board’s integrity.

- Soldering for Reliability: Proper soldering not only improves reliability but also helps prevent moisture intrusion, which can cause metallographic changes and assembly issues on old PCB multilayer boards.

Whether in the manufacturing assembly process or during practical use, ensuring the reliable performance of multi-sided PCB boards is paramount to their functionality and longevity.