The Significance of Copper-Clad Laminate in PCB Manufacturing

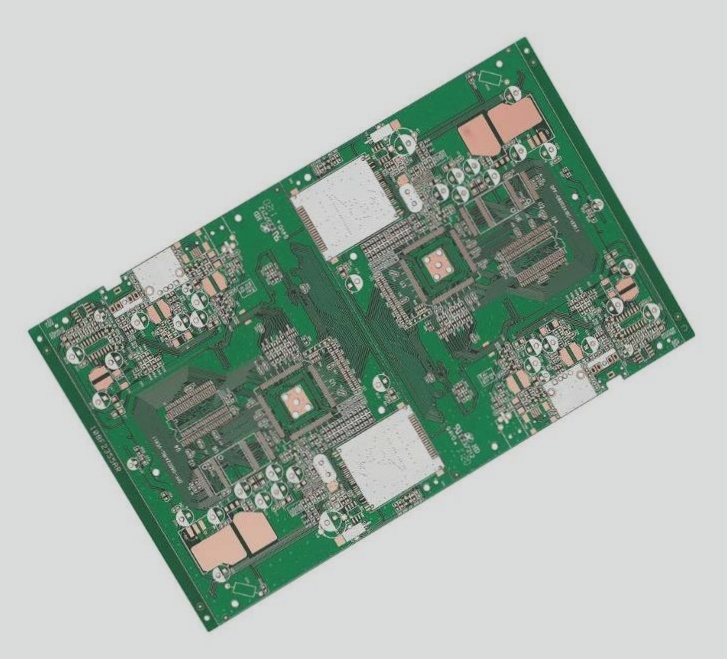

Copper-clad laminate plays a vital role as a substrate material in the production of PCBs, serving as the core material in the initial stages of PCB manufacturing. It consists of a substrate, copper foil, and adhesive, forming the primary component of a circuit board. The laminate is created by impregnating electronic glass fibers or other reinforcing materials with resin, with one or both sides coated in copper.

Applications of Copper-Clad Laminate

- Electronic Communication Field: Widely utilized in mobile phones, computers, communication devices, and network equipment, with a significant impact on mobile phone performance.

- Computer Field: Essential in computer hardware, including power boards, motherboards, expansion cards, and memory modules.

- Consumer Electronics: Increasingly used in products like smartwatches and smart homes.

- Automotive Electronics: Commonly found in in-car entertainment systems, navigation systems, and body control systems.

Role of PCB Copper Coating

- Enhanced Conductivity: Improves electrical connections between components, reduces signal loss, and minimizes resistance on circuit boards.

- Mechanical Strength and Corrosion Resistance: Enhances the board’s durability, protecting it from external pressure, wear, oxidation, and corrosion.

- Electromagnetic Interference Reduction: Forms a grounding or power layer to shield against electromagnetic interference, crucial for high-frequency circuits.

Copper-clad laminate serves as a fundamental material for PCBs, fulfilling key functions such as conductivity, insulation, support, and signal transmission.