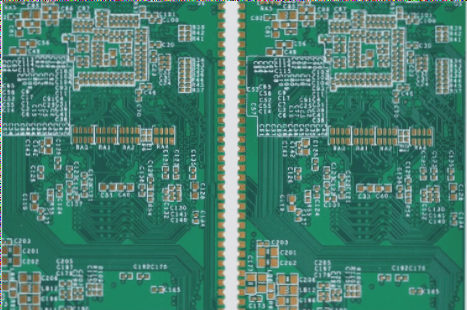

1. Bubbles can form between the traces of the FPC flexible circuit board or along the edge of a single trace.

The main cause: Bubbles between two or more traces typically result from narrow trace spacing and high trace profiles. During the screen printing process, the solder mask may fail to fully cover the substrate, allowing air or moisture to remain between the solder mask and the substrate. During curing and exposure, this trapped gas expands due to heat, causing the trace to rise excessively. As the squeegee presses against the trace, the increased height of the trace changes the angle between the squeegee and the trace, preventing the solder mask from reaching the base of the trace. This creates a pocket of gas between the trace base and the solder mask, which, upon heating, leads to bubble formation.

Solution: During screen printing, visually inspect whether the solder mask material is fully applied to both the substrate and the sidewalls of the traces. Additionally, closely monitor the electroplating process to control current levels precisely.

2. **Solder Masks and Pinholes in the Holes of the FPC Flexible Circuit Board**

**Main Cause**: The primary issue arises when the FPC flexible circuit board is not promptly printed with paper during the screen printing process, leading to excessive residual ink accumulation in the screen. Under the pressure of the squeegee, this excess ink can be pushed into the holes. Additionally, a low mesh count on the screen can also contribute to the formation of holes in the solder mask. Dirt on the photoplate can prevent certain areas of the FPC from being exposed to light during the exposure process, resulting in pinholes in the pattern.

**Solution**: Ensure timely paper printing and choose a high-mesh screen for plate making. Regularly inspect the cleanliness of the photoplate during the exposure process.

3. **Blackening Signs on Copper Foil Lines Beneath the Solder Mask of the FPC Flexible Circuit Board**

**Main Cause**: This issue often occurs when the FPC flexible circuit board is not properly dried after being wiped, or when the surface of the printed board is contaminated by liquid splashes or handled improperly before the solder mask is applied.

**Solution**: Visually inspect the copper foil on both sides of the printed board for any signs of oxidation during the screen printing process.

4. **Dirt and Unevenness on the Surface of the FPC Flexible Circuit Board**

**Main Cause**: Surface dirt is typically caused by airborne particles such as flying hairs or other debris. Uneven surfaces usually result from not promptly printing paper during the screen printing process or failing to remove residual ink from the screen, which leads to an uneven surface texture.

**Solution**: The clean room must maintain strict cleanliness standards, ensuring that only authorized personnel are present. Regular cleaning of the room is essential. Additionally, timely paper printing and the removal of residual ink from the screen during screen printing are crucial to preventing surface issues.

5. **Ghosting and Cracking on the FPC Flexible Circuit Board**

**Main Cause**: Ghosting occurs due to poor alignment of the FPC flexible circuit board during screen printing and the failure to remove residual ink from the screen in time. This results in regular ink marks adjacent to the FPC pads. Cracking typically occurs because of insufficient exposure during the FPC exposure process, which leads to small cracks on the surface of the board.

**Solution**: Ensure that the paper is firmly positioned using positioning pins and remove residual ink from the screen promptly. Properly calibrate exposure settings to ensure the exposure lamp energy and time are optimized, typically between 9-11 exposure levels, to avoid cracks.

6. **Inconsistent Color on Both Sides of the FPC Flexible Circuit Board and Issues with Skip Printing or “Flying White”**

**Main Cause**: Discrepancies in the number of squeegee passes on both sides of the screen can result in uneven color. Mixing new and old inks can also cause color inconsistency, where one side might use fresh, well-mixed ink while the other uses older ink. Skip printing may occur if the electroplating current is too high or the plating is too thick, causing the pattern lines to rise excessively. This can lead to areas without ink, especially when the squeegee blade and frame are not aligned properly, or if there are gaps in the squeegee.

**Solution**: Maintain consistent squeegee passes on both sides and avoid mixing new and old inks. Control the electroplating current and ensure that the squeegee blade is in good condition without any gaps.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me

The main cause: Bubbles between two or more traces typically result from narrow trace spacing and high trace profiles. During the screen printing process, the solder mask may fail to fully cover the substrate, allowing air or moisture to remain between the solder mask and the substrate. During curing and exposure, this trapped gas expands due to heat, causing the trace to rise excessively. As the squeegee presses against the trace, the increased height of the trace changes the angle between the squeegee and the trace, preventing the solder mask from reaching the base of the trace. This creates a pocket of gas between the trace base and the solder mask, which, upon heating, leads to bubble formation.

Solution: During screen printing, visually inspect whether the solder mask material is fully applied to both the substrate and the sidewalls of the traces. Additionally, closely monitor the electroplating process to control current levels precisely.

2. **Solder Masks and Pinholes in the Holes of the FPC Flexible Circuit Board**

**Main Cause**: The primary issue arises when the FPC flexible circuit board is not promptly printed with paper during the screen printing process, leading to excessive residual ink accumulation in the screen. Under the pressure of the squeegee, this excess ink can be pushed into the holes. Additionally, a low mesh count on the screen can also contribute to the formation of holes in the solder mask. Dirt on the photoplate can prevent certain areas of the FPC from being exposed to light during the exposure process, resulting in pinholes in the pattern.

**Solution**: Ensure timely paper printing and choose a high-mesh screen for plate making. Regularly inspect the cleanliness of the photoplate during the exposure process.

3. **Blackening Signs on Copper Foil Lines Beneath the Solder Mask of the FPC Flexible Circuit Board**

**Main Cause**: This issue often occurs when the FPC flexible circuit board is not properly dried after being wiped, or when the surface of the printed board is contaminated by liquid splashes or handled improperly before the solder mask is applied.

**Solution**: Visually inspect the copper foil on both sides of the printed board for any signs of oxidation during the screen printing process.

4. **Dirt and Unevenness on the Surface of the FPC Flexible Circuit Board**

**Main Cause**: Surface dirt is typically caused by airborne particles such as flying hairs or other debris. Uneven surfaces usually result from not promptly printing paper during the screen printing process or failing to remove residual ink from the screen, which leads to an uneven surface texture.

**Solution**: The clean room must maintain strict cleanliness standards, ensuring that only authorized personnel are present. Regular cleaning of the room is essential. Additionally, timely paper printing and the removal of residual ink from the screen during screen printing are crucial to preventing surface issues.

5. **Ghosting and Cracking on the FPC Flexible Circuit Board**

**Main Cause**: Ghosting occurs due to poor alignment of the FPC flexible circuit board during screen printing and the failure to remove residual ink from the screen in time. This results in regular ink marks adjacent to the FPC pads. Cracking typically occurs because of insufficient exposure during the FPC exposure process, which leads to small cracks on the surface of the board.

**Solution**: Ensure that the paper is firmly positioned using positioning pins and remove residual ink from the screen promptly. Properly calibrate exposure settings to ensure the exposure lamp energy and time are optimized, typically between 9-11 exposure levels, to avoid cracks.

6. **Inconsistent Color on Both Sides of the FPC Flexible Circuit Board and Issues with Skip Printing or “Flying White”**

**Main Cause**: Discrepancies in the number of squeegee passes on both sides of the screen can result in uneven color. Mixing new and old inks can also cause color inconsistency, where one side might use fresh, well-mixed ink while the other uses older ink. Skip printing may occur if the electroplating current is too high or the plating is too thick, causing the pattern lines to rise excessively. This can lead to areas without ink, especially when the squeegee blade and frame are not aligned properly, or if there are gaps in the squeegee.

**Solution**: Maintain consistent squeegee passes on both sides and avoid mixing new and old inks. Control the electroplating current and ensure that the squeegee blade is in good condition without any gaps.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me