Latest Trends in PCB Technology

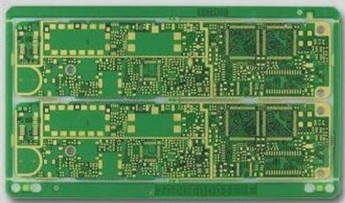

- High-density arbitrary layer interconnection printed circuit board

- Integrated printed circuit board

- High heat dissipation metal substrate

- High frequency and high-speed printed circuit board

Manufacturing processes for HDI with different hierarchical structures vary in complexity. The more complex the structure, the more challenging it is to manufacture. Key technological characteristics include “step connection,” “wrong hole connection,” “cross-layer connection,” and “stacked hole connection.” Ultra-high-density arbitrary-layer interconnected printed circuit boards cater to the demand for lightweight, thin, and multifunctional electronic products like smartphones, notebook computers, digital cameras, and LCD TVs.

Integrated printed circuit boards integrate electronic components into the board structure, enhancing system functionality, reliability, signal transmission performance, and cost-effectiveness. This technology supports the miniaturization of electronic devices and is gaining traction globally, with breakthroughs in materials and manufacturing processes.

High heat dissipation metal substrates utilize superior thermal conductivity to dissipate heat from high-power components. They are compatible with surface mount technology, reducing product volume and assembly costs while enhancing mechanical durability. Buried metal-based printed circuit boards offer advanced heat dissipation design concepts, providing excellent heat dissipation performance, flexible design options, lightweight construction, and compatibility with existing PCB production processes.

The demand for high-frequency and high-speed printed circuit boards is increasing due to the growing need for faster and more efficient electronic devices. These boards are designed to handle rapid signal transmission and are crucial for applications such as telecommunications, data centers, and high-speed computing.

Evolution of High-Frequency and High-Speed Printed Circuits

- High-frequency and high-speed printed circuits have a rich history, with roots in military applications dating back to the late 20th century.

- In recent years, frequency bands once reserved for military use have been repurposed for civilian applications, driving advancements in high-frequency and high-speed information transmission technologies.

- This shift has revolutionized industries by enabling long-distance communication, telemedicine surgery, and automated control of large logistics warehouses.

- The electronic components and printed circuit board industries catering to high-frequency signal transmission face stringent technical requirements, including precise impedance control, smooth metal connections, and specific line width specifications.

- Technological advancements have fueled the growth of electronic products, with demand projected to increase significantly in the coming years.

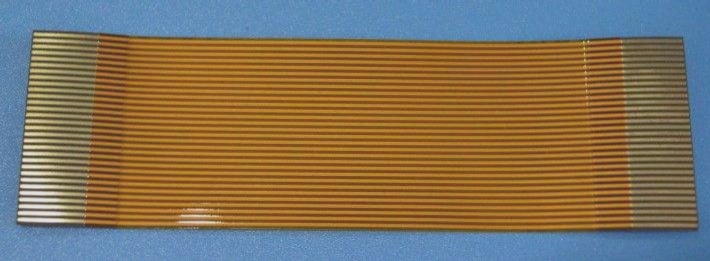

Rigid-Flex Printed Board Technology

- The demand for miniaturization and high density in electronic components and PCBs has surged due to the development of high-performance electronic devices.

- Innovations in laminated multilayer board manufacturing have led to the widespread adoption of various boards in electronic devices.

- Mobile devices, such as digital cameras and portable gadgets, require compact designs with efficient space utilization for functional components.

- Rigid-flex PCBs, a combination of small build-up multilayer boards and flexible boards, offer space-saving solutions by integrating rigid PCBs and FPCs without the need for additional connectors.

- Due to their compact nature and mountability, rigid-flex PCBs are increasingly popular in mobile devices.

If you require further modifications or additional details, please do not hesitate to reach out!