PCBA is now a widely adopted method for circuit board production and processing. Many manufacturers are increasingly outsourcing their PCBA production to specialized OEM companies, which helps alleviate some of their operational pressure. However, with numerous PCBA OEMs available in the market, many individuals are unsure how to select a suitable manufacturing partner. Today, I will provide a detailed guide on “How to choose PCBA foundry manufacturers and what types exist.”

1. How to choose a PCBA foundry manufacturer?

1. When selecting a PCBA OEM manufacturer, customers should thoroughly investigate the manufacturer’s foundational aspects, particularly verifying their compliance and professionalism.

1. Regarding formality, you can assess it through relevant qualifications, such as whether it has obtained ISO9001 quality management system certification. It requires patience to fully grasp its electronic processing expertise.

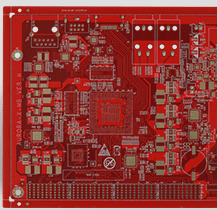

2. Visiting the PCBA factory in person is essential. Inspection aspects include the conditions of the SMT workshop, the DIP workshop, the office environment, and the overall morale of the employees. For example, check if their production equipment is sufficiently advanced, whether the PCBA production processes meet required standards, and if the workshop environment is clean and organized.

3. Customers should also consider the manufacturer’s recent development trajectory. A consistent upward trend can reflect the manufacturer’s overall strength and suitability for collaboration.

4. To ensure the quality of PCB boards and electronic components from PCBA foundries, it’s important to look at the reputable companies they collaborate with. Check if they partner with well-known medium to large enterprises or provide comprehensive PCBA solutions for recognized brands. Additionally, observe if they are engaged in currently trending areas in the electronics field to gain insight into their processing capabilities.

5. Furthermore, it’s crucial to investigate whether the manufacturer has established effective quality control and comprehensive procurement capabilities for electronic components. Assess whether they maintain long-term, stable relationships with agents and have advantages in supply cycles and costs.

6. Types of PCBA foundry materials

1. Technical

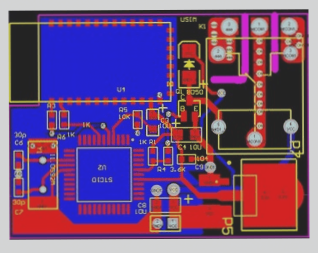

Their main capabilities focus on program R&D, both forward and reverse engineering, product design, and they also offer related PCBA processing and material procurement services during product development.

2. Processing type

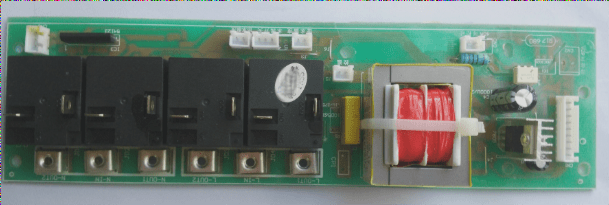

Processing companies typically have multiple SMT production lines and DIP post-welding lines, along with complete testing equipment, three anti-features, and potting glue.

1. How to choose a PCBA foundry manufacturer?

1. When selecting a PCBA OEM manufacturer, customers should thoroughly investigate the manufacturer’s foundational aspects, particularly verifying their compliance and professionalism.

1. Regarding formality, you can assess it through relevant qualifications, such as whether it has obtained ISO9001 quality management system certification. It requires patience to fully grasp its electronic processing expertise.

2. Visiting the PCBA factory in person is essential. Inspection aspects include the conditions of the SMT workshop, the DIP workshop, the office environment, and the overall morale of the employees. For example, check if their production equipment is sufficiently advanced, whether the PCBA production processes meet required standards, and if the workshop environment is clean and organized.

3. Customers should also consider the manufacturer’s recent development trajectory. A consistent upward trend can reflect the manufacturer’s overall strength and suitability for collaboration.

4. To ensure the quality of PCB boards and electronic components from PCBA foundries, it’s important to look at the reputable companies they collaborate with. Check if they partner with well-known medium to large enterprises or provide comprehensive PCBA solutions for recognized brands. Additionally, observe if they are engaged in currently trending areas in the electronics field to gain insight into their processing capabilities.

5. Furthermore, it’s crucial to investigate whether the manufacturer has established effective quality control and comprehensive procurement capabilities for electronic components. Assess whether they maintain long-term, stable relationships with agents and have advantages in supply cycles and costs.

6. Types of PCBA foundry materials

1. Technical

Their main capabilities focus on program R&D, both forward and reverse engineering, product design, and they also offer related PCBA processing and material procurement services during product development.

2. Processing type

Processing companies typically have multiple SMT production lines and DIP post-welding lines, along with complete testing equipment, three anti-features, and potting glue.