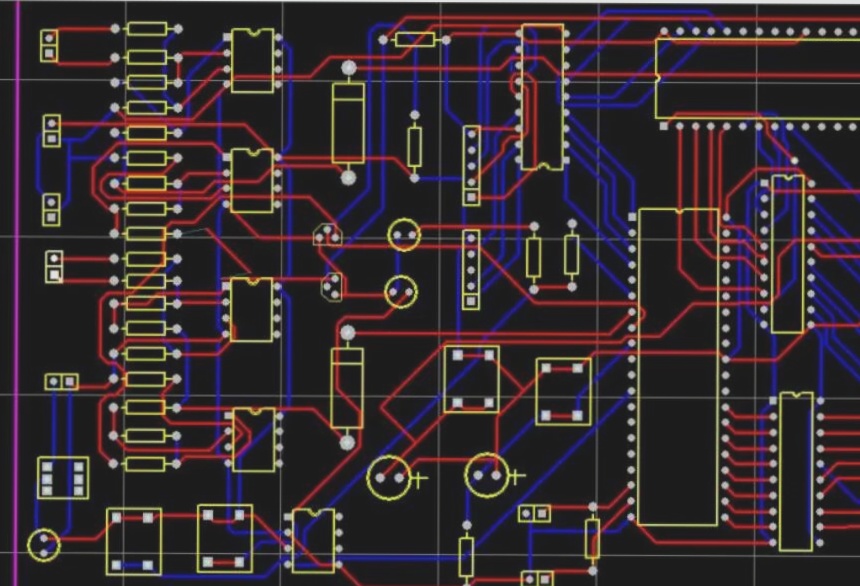

Before mass production of PCB boards, it is essential for the customer to provide details such as materials, size, quantity, and other parameters, particularly for high-frequency circuit boards. The manufacturer will then create a prototype of the PCB board based on the provided parameters. Once the prototyping is complete, both parties will need to communicate and negotiate any potential issues before proceeding to mass production based on the customized quantity. The following article will provide an overview.

The Purpose of PCB Board Prototyping:

1. Assess the capabilities of the PCB manufacturers.

2. Minimize the defective rate during PCB production.

3. Establish a strong foundation for future mass production.

The following are the parameters that need to be provided for PCB board prototyping:

Specific requirements include (to be provided in a word document or PCB file description):

1. Guidelines for sheet selection.

2. Description of sheet thickness.

3. Explanation of copper skin thickness on the circuit board.

4. Specifications for selecting solder mask color.

5. Special production requirements and description of special layers.

6. Required dimensional tolerance details.

7. Quantity of samples required.

8. Imposition requirements that are necessary.

The Purpose of PCB Board Prototyping:

1. Assess the capabilities of the PCB manufacturers.

2. Minimize the defective rate during PCB production.

3. Establish a strong foundation for future mass production.

The following are the parameters that need to be provided for PCB board prototyping:

Specific requirements include (to be provided in a word document or PCB file description):

1. Guidelines for sheet selection.

2. Description of sheet thickness.

3. Explanation of copper skin thickness on the circuit board.

4. Specifications for selecting solder mask color.

5. Special production requirements and description of special layers.

6. Required dimensional tolerance details.

7. Quantity of samples required.

8. Imposition requirements that are necessary.