PCB Circuit Maintenance Techniques

As electronic products continue to advance, the need for PCB circuit maintenance has become more prevalent. Below are several methods and techniques for effectively maintaining circuit boards:

1. Examination of Physical Damage

- Check for deformations or component breakage caused by dropping.

- Inspect chip sockets for proper handling requirements.

- Ensure correct chip insertion to prevent misalignment and potential damage.

- Verify correct terminal insertion to avoid shorts.

2. Checking for Burnt Components

When examining the circuit board, look for burnt components such as resistor-capacitor diodes. Use a multimeter to measure resistance and identify damaged parts that require replacement.

3. Inspection of Integrated Circuits

Inspect integrated circuits like 74 series CPUs for cracks or discoloration, as these issues indicate potential damage that may necessitate chip replacement.

4. Examination of Traces and Vias

Check for peeling or burnt traces on the circuit board, and ensure that deep copper vias are not detached from their pads.

5. Fuse Analysis

Examine fuses on the circuit board to determine if they have melted, using a multimeter if necessary to confirm their status.

6. Troubleshooting Overcurrent Issues

Analyze the cause of overcurrent by examining the circuit board’s schematic and identifying burnt components. Utilize experience to pinpoint problem areas and determine the root cause of failures.

7. Static Measurement for Digital Circuits

For digital circuits, use a multimeter to check for short circuits between the power supply and ground. Identify potential issues by measuring specific chip pins and investigating further if a short circuit is detected.

These maintenance steps provide a foundational understanding of circuit board upkeep, especially for complex boards that may require in-depth analysis.

PCB Maintenance Guide

1. Use a multimeter to measure diodes and ensure proper functionality. The resistance should typically read tens to hundreds of ohms, with diode failure often caused by excessive current.

2. Measure capacitance with the multimeter’s resistance setting to check for shorts. This helps identify if the issue lies with the component or the connecting circuit.

3. Assess the resistance of transistors on the circuit board to determine their performance. Resistance measurement is essential, especially in circuits with pull-up resistors on the bus.

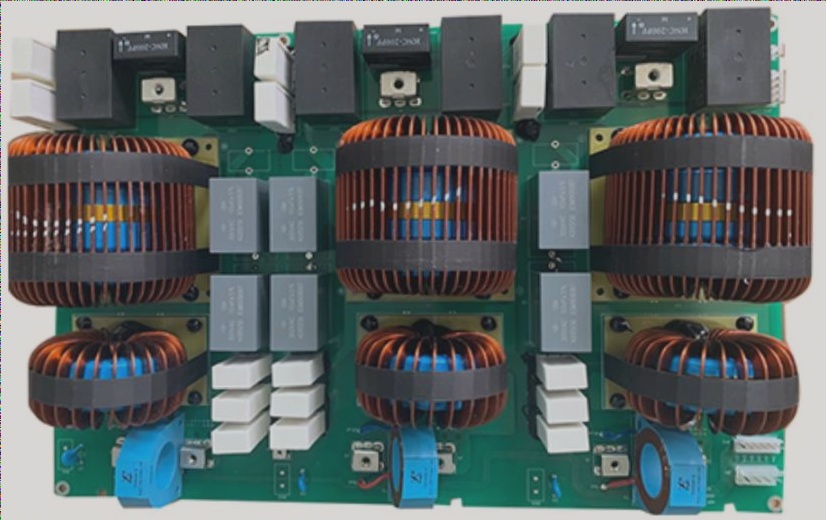

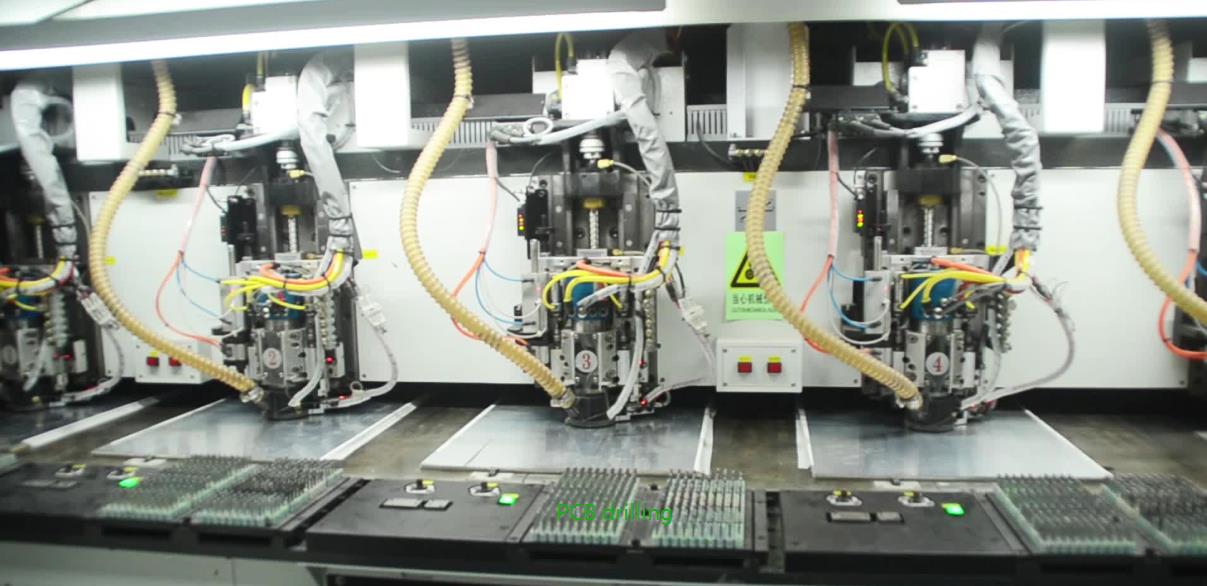

4. Large PCB manufacturers utilize online measurement methods for maintenance. This facilitates standardized debugging and problem identification, subdividing issues into specific components.

5. Steps for online measurement:

- Ensure all necessary power supplies (5V, 12V, 24V) are connected to the circuit board.

- Use an oscilloscope to measure the gate circuit and assess logic levels.

- Check crystal oscillators with an oscilloscope for output, replacing damaged components if necessary.

- Measure the digital address control bus to confirm the signal’s normalcy.

6. The online measurement method involves comparing functioning and non-functioning boards for diagnosis, completing circuit board maintenance effectively.

7. This guide covers circuit board maintenance techniques: observational methods, static measurements, and dynamic approaches. While new instruments are emerging, proficiency in basic tools like multimeters and oscilloscopes remains crucial for electronic engineers.