How to Improve EMC Performance in PCB Design

One way to mitigate edge radiation effects and enhance electromagnetic interference performance is by retracting the power layer to confine the electric field within the grounding layer. Reducing the power layer by specific measurements can significantly limit the electric field emitted from the edges of the board.

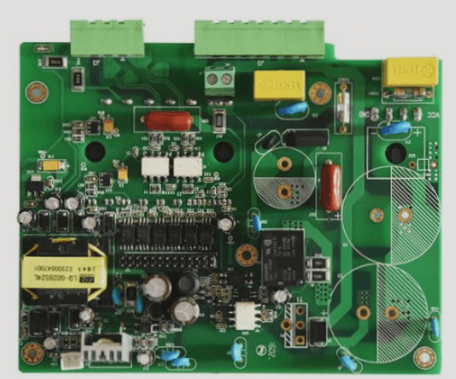

Ground Plane Size and Shielding

Ensuring that the ground plane is larger than the power or signal layers is crucial to reduce external radiation interference. By following the 20H principle and maintaining a specific distance between traces, you can effectively shield the PCB from outside disturbances.

Implementing the 3W and 20H Principles

- 3W Principle: Maintain a center-to-center distance between traces that is at least three times the trace width. This principle is essential for proper signal transmission and interference prevention.

- 20H Principle: To adhere to this principle, reduce the power layer by a specific measurement from the ground layer when dividing the plane layers. This step is critical for optimizing PCB performance.

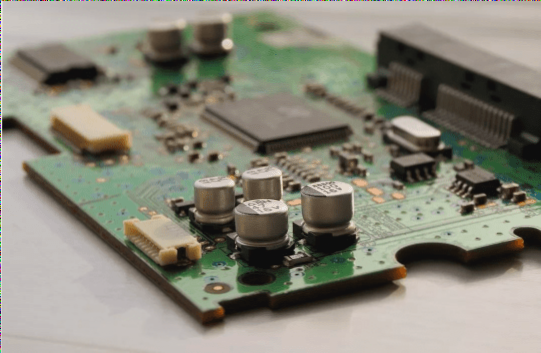

Types of PCB Signal Lines

PCB signal lines are typically classified into microstrip lines and strip lines, each with unique characteristics and applications. Microstrip lines offer faster signal transmission speeds, while strip lines provide better shielding from external interference.

Understanding EMC in PCB Design

EMC, or Electromagnetic Compatibility, is essential for devices to operate effectively in their electromagnetic environments without causing or experiencing harmful interference. Ensuring EMC for sensors involves managing electromagnetic interference and maintaining immunity to external disturbances.

Design Methods for Analog and Digital Grounds

When designing PCB layouts, distinguishing between analog and digital grounds is crucial for optimal performance. Various methods, such as direct separation, magnetic beads, and capacitive coupling, can be employed to ensure proper grounding and minimize interference.

PCB Grounding Techniques for Noise Suppression

- Inductive Coupling: Utilize inductors to link digital and analog grounds, with inductance values typically in the range of microhenries (uH) to tens of microhenries.

- Zero-Ohm Resistors: Place a zero-ohm resistor between the digital and analog grounds.

Capacitors play a crucial role in isolating DC currents and establishing floating grounds. Failure to DC-couple a capacitor can result in voltage differentials and static charge accumulation, potentially causing discomfort upon enclosure contact. When capacitors and magnetic beads are used concurrently, they may redundantly interact, with the magnetic beads allowing DC to pass through, rendering the capacitors ineffective. When arranged in series, their combined effectiveness diminishes.

Inductors, while effective in certain scenarios, tend to be bulky and possess numerous stray parameters, leading to performance instability and less precise control over distributed parameters. Inductance can also introduce notch effects and LC resonance, impacting noise characteristics.

The equivalent circuit of a magnetic bead functions as a band-rejection filter, suppressing noise at specific frequencies. However, selecting the appropriate magnetic bead for unpredictable noise frequencies can be challenging, making them less optimal. In contrast, zero-ohm resistors provide a restricted current path that effectively constrains loop currents and suppresses noise across all frequencies, offering a more dependable solution compared to magnetic beads.

In essence, the fundamental principle dictates that analog and digital grounds should converge at a singular point. It is advisable to interconnect various ground types using 0-ohm resistors, employ magnetic beads when incorporating high-frequency components into the power supply, utilize small capacitors for coupling high-frequency signal lines, and leverage inductors for high-power, low-frequency applications.

If you require PCB manufacturing services, feel free to reach out to me. Contact me