Challenges and Solutions in Implementing Robots for Automated Production in the PCB Industry

From single-station or single-line applications to multi-line setups, fully implementing robots for automated production remains a challenge for many PCB companies. These companies face significant investment costs for such a transformation. However, they can undertake incremental changes by upgrading qualified single stations and single lines, gradually expanding automation as they achieve tangible results.

The Current Landscape of the PCB Industry

The PCB industry is both technology and capital-intensive but still heavily relies on labor. Despite the prevalence of automated equipment, manual labor and assembly line operations remain necessary. Due to various factors such as industrial transfer, new labor laws, and changing workforce demographics, PCB manufacturers are facing growing challenges such as labor shortages, escalating costs, and negative effects on production schedules, product quality, and profitability. As robot performance improves and costs decline, the shift towards the “automation equipment + industrial robot operation” model is becoming the ultimate trend in the PCB industry’s transformation and development.

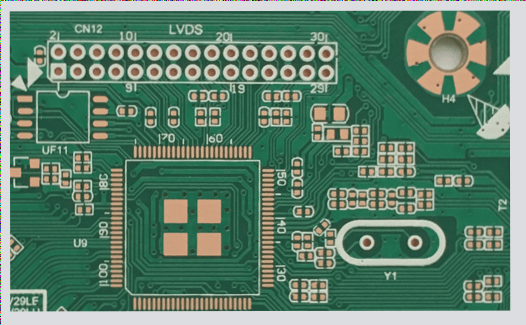

Representative Robot Application Cases

- Six-axis multi-joint robot for AOI inspection process: By utilizing a six-axis multi-joint robot, workers can be replaced in loading, turning, and unloading the AOI machines, significantly increasing efficiency and reducing health hazards.

- SCARA robot for circuit board coil inspection process: Employing a SCARA robot improves detection efficiency and reduces the risk of quality issues from undetected faults in PCB coils.

- DELTA robot for small circuit board boxing process: The Delta800 robot, combined with a vision system, autonomously sorts and selects qualified FPCs, matching manual labor efficiency.

Advantages of Industrial Robots in the PCB Industry

- Reduction in labor and increased efficiency: Robots can perform high-speed tasks, outperforming manual labor and reducing costs.

- Improved operational accuracy and product quality: Robots equipped with programming and vision systems ensure precise positioning and enhanced product quality.

- Enhanced worker health and safety: Robots reduce potential health and safety risks in the working environment, leading to a safer workplace.

Benefits of Industrial Robots in the PCB Industry

- Reduction in inefficiency and quality issues: Industrial robots eliminate productivity loss, enhance quality, and decrease accidents caused by repetitive tasks.

- Optimized workflows and reduced workspace requirements: Robots streamline processes, minimizing the need for extensive workspaces.

- Material consumption reduction: Industrial robots enhance efficiency and minimize material waste in handling.

- Continuous 24-hour operation in low-light environments: Robots can operate continuously, even in dim lighting, ensuring consistent production.

- Flexible manufacturing processes: With the rise of small batch orders in the PCB industry, industrial robots offer increased flexibility in production, leading to faster order completion.

- Enhanced brand image and competitiveness: Integrating industrial robots elevates automation levels, enhancing product quality, production efficiency, and cost control, ultimately strengthening a company’s competitive position in the market.

Future Prospects of Industrial Robots in the PCB Industry

The use of industrial robots in the PCB industry is still evolving, with several challenges to overcome. Many production lines in the PCB industry handle non-standard products, requiring robots to navigate workspace constraints, equipment limitations, and diverse PCB materials. This necessitates sensor integration to enhance robot functionality and training for employees to operate and maintain robots effectively.

Looking ahead, the following trends are expected in robot application within the PCB industry:

- Shift from single-station or single-line to multi-line applications: PCB companies can gradually introduce robots in specific stations or lines, moving towards full automation as outcomes improve.

- Integration of robots with other intelligent equipment like AGVs: Combining robots and AGVs can streamline material transfer between production lines, enhancing workflow efficiency.

- Full automation in new factory setups: Future factories will incorporate robots and AGVs from the start, eliminating the need for retrofitting existing facilities.

- Industrial robots and the Internet of Things (IoT): The fusion of robotics and IoT technologies will make manufacturing processes smarter, more adaptable, and responsive to changing production demands.

In conclusion, the extensive use of industrial robots in the PCB industry represents an inevitable and promising advancement for the future.