Methods for Designing Jigsaw Puzzles

There are various methods for designing jigsaw puzzles, making it challenging to determine the best technique and quantity of puzzles for new product trials.

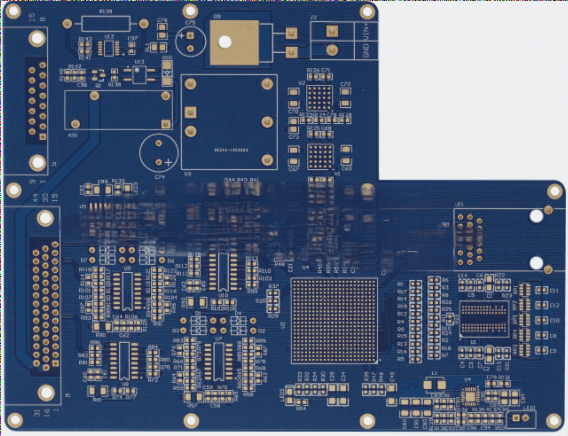

PCB Design Engineers and Structural Requirements

PCB design engineers prioritize meeting product structural requirements based on characteristics like limitations, height restrictions, and constraints. Considerations for sheet utilization and production efficiency are crucial during PCB manufacturing and SMT processing.

Impact of Thermal Expansion on Product Reliability

Thermal expansion resulting from geometric dimensions and PCB mounting techniques can significantly impact product reliability and performance, increasing complexity and manufacturing costs in SMT production.

Enhancing SMT Production Efficiency

Utilizing jigsaw methods to enhance SMT production efficiency is essential, drawing from experience shared by SMT process engineers.

Splicing Methods in SMT Production Line

- To enhance utilization rate in the SMT production line, common splicing methods include AAAA or AB, considering product complexity, placement cycle balance, and component issues during reflow.

- The AABB design simplifies equipment configuration and processes, enhancing SMT line speed and efficiency for rapid PCBA product production.

- The AAA/BBB design, more suitable for most factories, allows for stable production processes and improved efficiency by considering component layout and equipment allocation.