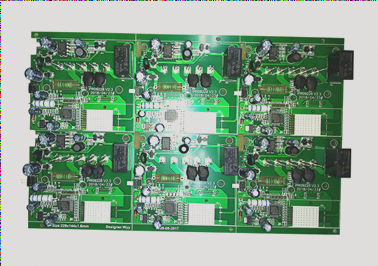

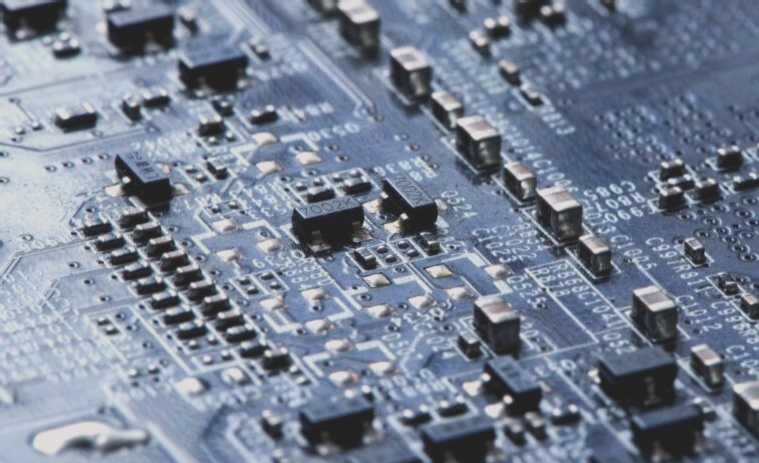

At first glance, regardless of the inherent quality of the PCB, its surface appears uniform. However, it is through this surface that we can identify crucial differences that significantly impact the durability and functionality of the PCB over its lifespan.

Whether during the PCBA manufacturing assembly process or in actual operation, a PCB must exhibit reliable performance, which is vital. Aside from associated costs, any defects during assembly can be carried over to the final product, potentially leading to malfunctions in use and resulting in claims. From this perspective, it’s fair to say that the expense of a high-quality PCB is minimal.

In all market segments, especially those producing products for critical applications, the repercussions of such failures can be dire.

When evaluating PCB prices, these considerations must be taken into account. While the initial investment in reliable, guaranteed, and long-lasting products may be higher, they prove to be cost-effective over time.

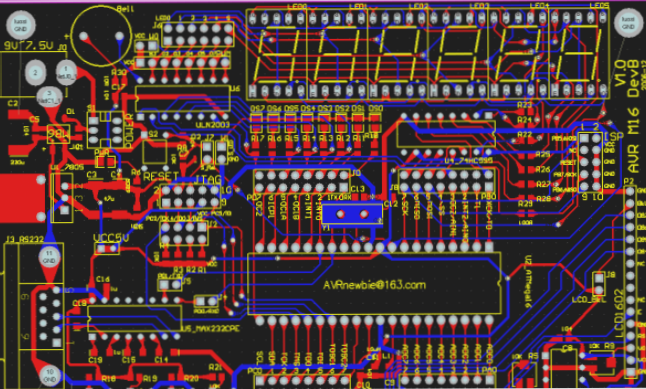

High-reliability circuit boards should possess the following 14 essential characteristics:

1. A hole wall copper thickness of 25 microns

Benefit:

Enhances reliability, including improved resistance to z-axis expansion.

**Risk of not doing this:**

Creating holes or experiencing outgassing, electrical connectivity issues during assembly (inner layer separation, hole wall breakage), or failures under load conditions in actual usage. IPC Class 2 (the standard adopted by most PCB manufacturers) mandates 20% less copper plating.

1. **No welding repair or open circuit repair**

**Benefit:**

A flawless circuit ensures reliability and safety, with no maintenance or risk.

**Risk of not doing this:**

Improper repairs can compromise the circuit board. Even if repairs are deemed ‘proper,’ risks of failure under load conditions (e.g., vibration) remain, potentially leading to actual usage failures.

2. **Cleanliness requirements exceeding IPC specifications**

**Benefit:**

Enhancing PCB cleanliness can boost reliability.

**Risk of not doing this:**

Residues and solder buildup on the circuit board threaten the solder mask. Ionic residues may lead to corrosion and contamination on the soldering surface, resulting in reliability issues (bad solder joints/electrical failures) and an increased likelihood of actual failures.

3. **Strictly controlling the service life of each surface treatment**

**Benefit:**

Enhances solderability and reliability, while reducing moisture intrusion risks.

**Risk of not doing this:**

Metallurgical changes in older circuit board treatments can cause soldering issues. Moisture intrusion may lead to problems such as delamination and separation (open circuits) of the inner layer and hole wall during assembly and actual use.

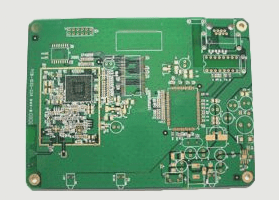

4. **Use internationally recognized substrates—avoid “local” or unknown brands**

**Benefit:**

Improves reliability and assures known performance.

**Risk of not doing this:**

Subpar mechanical performance can hinder the circuit board’s expected performance during assembly, leading to issues like delamination, disconnection, and warping. Deteriorated electrical characteristics may result in inadequate impedance performance.

5. **Tolerance of copper clad laminate meets IPC 4101 Class B/L requirements**

**Benefit:**

Tightly controlling the dielectric layer thickness minimizes deviation in expected electrical performance.

**Risk of not doing this:**

Electrical performance may fail to meet specifications, causing significant variation in output/performance among components from the same batch.

6. **Define solder mask materials to ensure compliance with IPC-SM-840 Class T requirements**

**Benefit:**

NCAB Group acknowledges “excellent” inks, ensuring ink safety and compliance with UL standards.

**Risk of not doing this:**

Inferior inks can lead to adhesion, flux resistance, and hardness issues, causing the solder mask to detach from the PCB and potentially result in copper circuit corrosion. Poor insulation can lead to short circuits from accidental electrical continuity or arcing.

7. **Defining tolerances for shapes, holes, and other mechanical features**

**Benefit:**

Strict tolerance control enhances product dimensional quality—improving fit, shape, and functionality.

**Risk of not doing this:**

Assembly issues, such as alignment or fitting problems (discovered only upon completion), may arise. Increased size deviation can complicate base installation.

8. **NCAB specifies solder mask thickness, despite IPC lacking relevant regulations**

**Benefit:**

Enhances electrical insulation, reduces peeling or adhesion loss risks, and strengthens resistance to mechanical impact, regardless of where it occurs.

**Risk of not doing this:**

A thin solder mask can create adhesion, flux resistance, and hardness challenges, leading to detachment from the PCB and copper circuit corrosion. Insufficient insulation properties can result in short circuits from accidental conduction or arcing.

9. **Defining appearance and repair requirements, even when IPC does not**

**Benefit:**

Promotes care and safety during the manufacturing process.

**Risk of not doing this:**

Surface scratches, minor damages, and repairs may render the circuit board functional but visually unappealing. Additionally, hidden risks could impact assembly and actual use.

10. **Requirements for plug hole depth**

**Benefit:**

High-quality plug holes minimize assembly failure risks.

**Risk of not doing this:**

Chemical residues from gold deposit processes may remain in unfilled plug holes, affecting solderability. Hidden tin beads in the holes could cause short circuits during assembly or actual use.

11. **Peters SD2955 specifies the brand and model of peelable blue glue**

**Benefit:**

Specifying peelable blue glue prevents the use of “local” or inferior brands.

**Risk of not doing this:**

Substandard or cheap peelable glue may foam, melt, crack, or solidify during assembly, making it ineffective for peeling.

12. **NCAB implements specific approval and ordering procedures for each purchase order**

**Benefit:**

This program ensures all specifications are confirmed.

**Risk of not doing this:**

Without careful confirmation of product specifications, deviations may not be identified until PCB assembly or final product stages, which could be too late.

13. **Do not accept boards with scrapped units**

**Benefit:**

Avoiding partial assemblies helps customers enhance efficiency.

**Risk of not doing this:**

All defective boards necessitate special assembly procedures. If scrap units are not clearly marked (x-out) or isolated, there’s a risk of assembling known defective boards, wasting parts and time.

Whether during the PCBA manufacturing assembly process or in actual operation, a PCB must exhibit reliable performance, which is vital. Aside from associated costs, any defects during assembly can be carried over to the final product, potentially leading to malfunctions in use and resulting in claims. From this perspective, it’s fair to say that the expense of a high-quality PCB is minimal.

In all market segments, especially those producing products for critical applications, the repercussions of such failures can be dire.

When evaluating PCB prices, these considerations must be taken into account. While the initial investment in reliable, guaranteed, and long-lasting products may be higher, they prove to be cost-effective over time.

High-reliability circuit boards should possess the following 14 essential characteristics:

1. A hole wall copper thickness of 25 microns

Benefit:

Enhances reliability, including improved resistance to z-axis expansion.

**Risk of not doing this:**

Creating holes or experiencing outgassing, electrical connectivity issues during assembly (inner layer separation, hole wall breakage), or failures under load conditions in actual usage. IPC Class 2 (the standard adopted by most PCB manufacturers) mandates 20% less copper plating.

1. **No welding repair or open circuit repair**

**Benefit:**

A flawless circuit ensures reliability and safety, with no maintenance or risk.

**Risk of not doing this:**

Improper repairs can compromise the circuit board. Even if repairs are deemed ‘proper,’ risks of failure under load conditions (e.g., vibration) remain, potentially leading to actual usage failures.

2. **Cleanliness requirements exceeding IPC specifications**

**Benefit:**

Enhancing PCB cleanliness can boost reliability.

**Risk of not doing this:**

Residues and solder buildup on the circuit board threaten the solder mask. Ionic residues may lead to corrosion and contamination on the soldering surface, resulting in reliability issues (bad solder joints/electrical failures) and an increased likelihood of actual failures.

3. **Strictly controlling the service life of each surface treatment**

**Benefit:**

Enhances solderability and reliability, while reducing moisture intrusion risks.

**Risk of not doing this:**

Metallurgical changes in older circuit board treatments can cause soldering issues. Moisture intrusion may lead to problems such as delamination and separation (open circuits) of the inner layer and hole wall during assembly and actual use.

4. **Use internationally recognized substrates—avoid “local” or unknown brands**

**Benefit:**

Improves reliability and assures known performance.

**Risk of not doing this:**

Subpar mechanical performance can hinder the circuit board’s expected performance during assembly, leading to issues like delamination, disconnection, and warping. Deteriorated electrical characteristics may result in inadequate impedance performance.

5. **Tolerance of copper clad laminate meets IPC 4101 Class B/L requirements**

**Benefit:**

Tightly controlling the dielectric layer thickness minimizes deviation in expected electrical performance.

**Risk of not doing this:**

Electrical performance may fail to meet specifications, causing significant variation in output/performance among components from the same batch.

6. **Define solder mask materials to ensure compliance with IPC-SM-840 Class T requirements**

**Benefit:**

NCAB Group acknowledges “excellent” inks, ensuring ink safety and compliance with UL standards.

**Risk of not doing this:**

Inferior inks can lead to adhesion, flux resistance, and hardness issues, causing the solder mask to detach from the PCB and potentially result in copper circuit corrosion. Poor insulation can lead to short circuits from accidental electrical continuity or arcing.

7. **Defining tolerances for shapes, holes, and other mechanical features**

**Benefit:**

Strict tolerance control enhances product dimensional quality—improving fit, shape, and functionality.

**Risk of not doing this:**

Assembly issues, such as alignment or fitting problems (discovered only upon completion), may arise. Increased size deviation can complicate base installation.

8. **NCAB specifies solder mask thickness, despite IPC lacking relevant regulations**

**Benefit:**

Enhances electrical insulation, reduces peeling or adhesion loss risks, and strengthens resistance to mechanical impact, regardless of where it occurs.

**Risk of not doing this:**

A thin solder mask can create adhesion, flux resistance, and hardness challenges, leading to detachment from the PCB and copper circuit corrosion. Insufficient insulation properties can result in short circuits from accidental conduction or arcing.

9. **Defining appearance and repair requirements, even when IPC does not**

**Benefit:**

Promotes care and safety during the manufacturing process.

**Risk of not doing this:**

Surface scratches, minor damages, and repairs may render the circuit board functional but visually unappealing. Additionally, hidden risks could impact assembly and actual use.

10. **Requirements for plug hole depth**

**Benefit:**

High-quality plug holes minimize assembly failure risks.

**Risk of not doing this:**

Chemical residues from gold deposit processes may remain in unfilled plug holes, affecting solderability. Hidden tin beads in the holes could cause short circuits during assembly or actual use.

11. **Peters SD2955 specifies the brand and model of peelable blue glue**

**Benefit:**

Specifying peelable blue glue prevents the use of “local” or inferior brands.

**Risk of not doing this:**

Substandard or cheap peelable glue may foam, melt, crack, or solidify during assembly, making it ineffective for peeling.

12. **NCAB implements specific approval and ordering procedures for each purchase order**

**Benefit:**

This program ensures all specifications are confirmed.

**Risk of not doing this:**

Without careful confirmation of product specifications, deviations may not be identified until PCB assembly or final product stages, which could be too late.

13. **Do not accept boards with scrapped units**

**Benefit:**

Avoiding partial assemblies helps customers enhance efficiency.

**Risk of not doing this:**

All defective boards necessitate special assembly procedures. If scrap units are not clearly marked (x-out) or isolated, there’s a risk of assembling known defective boards, wasting parts and time.